Reducing PCB Stress: Tips for Better Performance

1. Minimizing Temperature Impact

Temperature plays a crucial role in PCB stress. Lowering reflow oven temperatures or adjusting heating and cooling rates can help prevent bending and warping. However, be cautious of potential solder shorts.

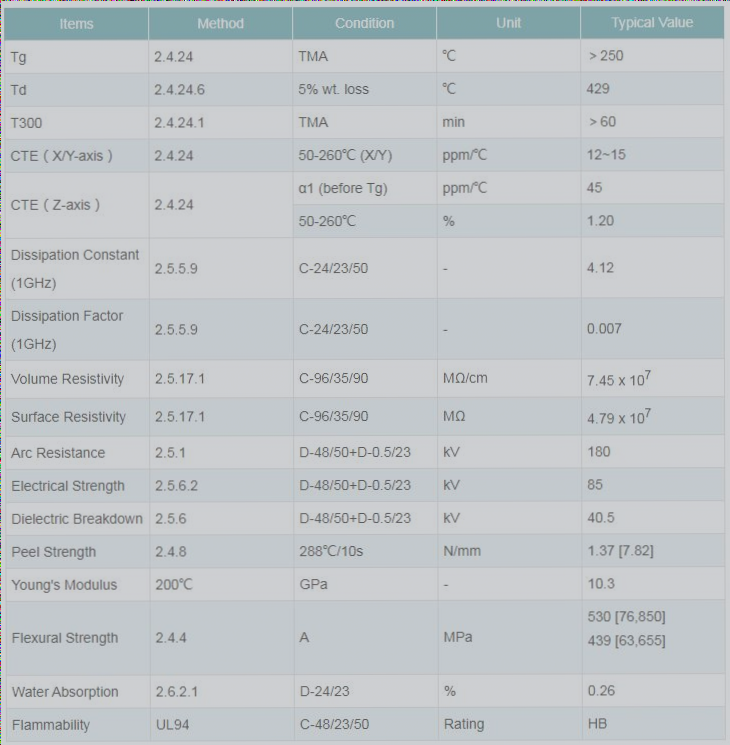

2. Opt for High Tg Materials

High Tg materials have a higher glass transition temperature, making them more resistant to deformation during reflow. While they come at a higher cost, they offer better stress tolerance.

3. Consider PCB Thickness

Thinner PCBs are popular for lightweight devices but can be prone to deformation. Opting for a 1.6mm thickness reduces the risk of bending and ensures rigidity post-reflow.

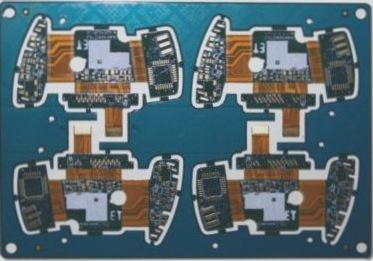

4. Reduce PCB Size and Puzzle Cuts

Positioning larger boards along the chain edge in reflow ovens can prevent denting and deformation. Orienting boards with the narrow edge facing the travel direction minimizes potential deformation.

5. Utilize Furnace Tray Fixtures

Reflow carriers or templates support PCBs during thermal expansion, reducing bending. Adding covers to clamp boards between pallets can further prevent warping, though it may increase costs.

6. Avoid V-Cuts for Sub-Boards

Using routers instead of V-Cuts for panel separation maintains the board’s structural integrity. Minimizing V-Cut depth can also help prevent issues.

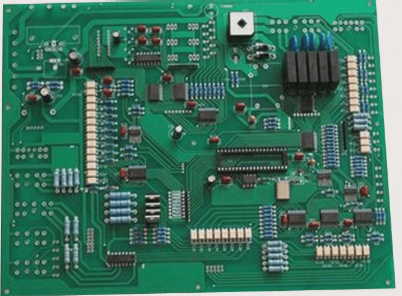

If you require PCB manufacturing services, feel free to contact us.