**Printed Circuit Board (PCB)** is the foundation for circuit components and devices in electronic products. It provides the necessary electrical connections between various circuit elements and devices. With the rapid advancement of electronic technology, the density of PCBs continues to increase. The quality of PCB design significantly impacts its ability to resist interference. Therefore, when designing a PCB, it is crucial to follow general design principles and meet the requirements for anti-interference.

### General Principles of PCB Design

To achieve optimal performance in an electronic circuit, both the placement of components and the routing of traces are crucial. For designing a PCB that balances quality and cost-effectiveness, the following general principles should be adhered to:

1. **PCB Layout**

The first consideration is the size of the PCB. A larger PCB size leads to longer traces, higher impedance, reduced noise immunity, and increased cost. On the other hand, a PCB that is too small can result in poor heat dissipation and increased susceptibility to interference between adjacent traces. Once the PCB size is determined, the next step is to position special components, followed by the arrangement of all circuit components based on functional units.

The following principles should be observed when positioning special components:

(1) Minimize the trace length between high-frequency components to reduce their parasitic parameters and mutual electromagnetic interference. Components that are sensitive to interference should not be placed too close to each other, and input and output components should be kept as far apart as possible.

(2) Some components or traces may carry a high potential difference, so it is important to increase the distance between them to prevent accidental short circuits due to discharge. High-voltage components should be placed in locations that are less accessible during troubleshooting or adjustments.

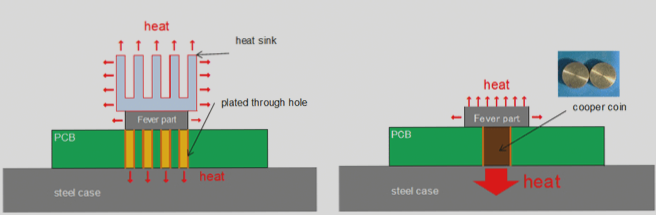

(3) Components weighing more than 15g should be secured with brackets before soldering. Large, heavy, or heat-generating components should not be mounted directly on the PCB but rather on the machine’s chassis or baseplate. Consideration should also be given to heat dissipation, and thermal components should be positioned away from other heat-generating parts.

(4) The layout of adjustable components such as potentiometers, adjustable inductance coils, variable capacitors, micro switches, etc., should take into account the structural requirements of the entire system. If adjustments are made inside the machine, these components should be placed on the printed circuit board in locations that facilitate easy access for adjustment. If adjustments are made externally, their positions should align with the adjustment knobs on the chassis panel.

(5) Space must be allocated for the positioning holes of the printed board and the fixed bracket.

When arranging all components on the circuit board, the following principles should be followed based on the functional units of the circuit:

(1) Position each functional circuit unit according to the flow of the circuit to ensure the layout supports efficient signal circulation, maintaining the signal direction as consistent as possible.

(2) Center each functional circuit around its core components and arrange surrounding components evenly, neatly, and compactly on the PCB. Minimize and shorten the leads and connections between components.

(3) For circuits operating at high frequencies, it is essential to account for the distributed parameters between components. Typically, components should be arranged in parallel as much as possible, as this not only improves the aesthetic but also simplifies installation, soldering, and mass production.

(4) Components at the edges of the circuit board should generally be placed no less than 2mm from the board’s edge. The optimal shape for a circuit board is rectangular, with an aspect ratio of 3:2 to 4:3. For circuit boards larger than 200x150mm, the mechanical strength of the board must also be considered.

**2. Wiring**

The wiring principles are as follows:

(1) Input and output wires should not run adjacent or parallel to each other whenever possible. In such cases, it is advisable to insert ground wires between the signal wires to minimize feedback coupling.

(2) The minimum width of the printed wire is determined by the adhesive strength between the wire and the insulating substrate, as well as the current passing through them. For example, with a copper foil thickness of 0.05mm and a wire width between 1-15mm, carrying a current of 2A, the temperature rise should not exceed 3°C. Therefore, a wire width of 1.5mm is typically sufficient. For integrated circuits, particularly digital circuits, a wire width between 0.02-0.3mm is generally chosen. However, it is preferable to use the widest traces possible, especially for power and ground connections. The minimum spacing between wires is determined by the insulation resistance and breakdown voltage. For integrated circuits, especially digital ones, spacing of 5-8mm is typically acceptable, depending on the manufacturing process.

(3) Printed conductor bends should generally be arc-shaped, as right angles or sharp corners can negatively affect electrical performance in high-frequency circuits. Additionally, large areas of copper foil should be avoided, as they can expand and detach due to prolonged heating. If large copper areas are necessary, using a grid pattern is recommended to help release volatile gases produced by the heating of the adhesive between the copper foil and the substrate.

**3. Pad**

The center hole of the pad should be slightly larger than the diameter of the component lead. If the pad is too large, it may result in poor soldering. The outer diameter (D) of the pad is generally at least (d + 1.2) mm, where “d” is the lead diameter. For high-density digital circuits, the minimum pad diameter may be (d + 1.0) mm.

**PCB and Circuit Anti-Interference Measures**

The anti-interference design of a printed circuit board is closely related to the specific circuit. Here, only a few common PCB anti-jamming measures are outlined.

**1. Power Line Design**

To minimize loop resistance, the width of the power line should be maximized according to the current requirements of the printed circuit board. Additionally, the power and ground lines should align with the direction of data transmission to improve noise immunity.

**2. Ground Wire Design**

The following principles should guide ground wire design:

(1) Digital and analog grounds should be separated. If both logic circuits and analog circuits exist on the same PCB, these grounds should be kept as separate as possible. For low-frequency circuits, the ground should be connected at a single point. If this is difficult to implement, a partial series connection can be used, followed by parallel grounding. For high-frequency circuits, grounding should be done at multiple points in series, with short, thick ground wires and a grid-like ground foil around the high-frequency components.

(2) Ground wires should be as thick as possible. Thin ground wires can cause voltage fluctuations, degrading noise immunity. The ground wire should be capable of carrying three times the maximum current expected on the PCB. If possible, the width should be 2-3mm or greater.

(3) Grounding should form a closed loop. For digital circuit-only boards, grounding is typically arranged in loops to enhance noise immunity.

**3. Decoupling Capacitor Configuration**

A standard practice for PCB design is to use appropriate decoupling capacitors at critical points on the PCB. General configuration guidelines for decoupling capacitors are as follows:

(1) Place a 10-100µF electrolytic capacitor across the power input. Ideally, this should be 100µF or more.

(2) In general, each integrated circuit chip should be paired with a 0.01µF ceramic capacitor. If space is limited, a 1-10pF capacitor can be used for every 4-8 chips.

(3) For components with weak noise immunity or those subject to large power changes when powered off, such as RAM and ROM storage devices, decoupling capacitors should be directly connected between the chip’s power and ground pins.

(4) Minimize the lead length for capacitors, particularly for high-frequency bypass capacitors.

Additionally, two points should be noted:

(1) When there are components such as contactors, relays, or buttons on the PCB, appropriate precautions must be taken during their operation to avoid interference.