Generally, everyone should understand the layout and wiring rules of a PCB board. However, the design rules of the RF board PCB board may not be as well-known. Today, let’s discuss the layout and wiring principles of the RF board PCB board.

RF board PCB board layout principle

1) Layout determination: Prior to starting the layout, it is important to have a comprehensive understanding of the board’s function, working frequency band, current and voltage, main RF device types, EMC, and related RF indicators. It is also crucial to clarify the stack structure, impedance control, external structure size, shielding cavity and cover size and position, and special device processing instructions (e.g. size and position of devices that need to be hollowed out and directly dissipated by the chassis). Furthermore, the power, heat dissipation, gain, isolation, sensitivity of the main RF device and the connection of filtering, biasing, and matching circuits should be specified. The impedance matching circuit guidelines recommended in the device manual or obtained through RF field analysis software simulation should also be considered for the power amplifier circuit.

2) Physical partition: The main components should be arranged according to the flow direction of the single board’s main signal. First, position the components on the RF path according to the RF port location and adjust their orientation to minimize the length of the RF path. In addition to general layout rules, it is important to consider how to reduce mutual interference and increase the anti-interference ability of each part to ensure sufficient isolation of multiple circuits. For circuit modules with insufficient isolation or sensitive and strong radiation sources, the use of metal shields to block RF energy from the RF area should be considered.

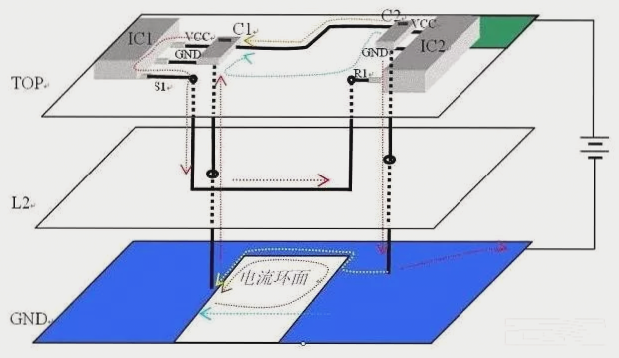

3) Electrical partition: The layout is generally divided into three parts: power supply, digital, and analog, which must be separated in space. Layout and wiring should not cross these areas. Additionally, efforts should be made to separate strong and weak current signals, digital and analog signals, and to arrange circuits that complete the same function within a certain range to minimize the signal loop area.

RF board PCB board wiring principles

1) Always keep digital circuits away from analog circuits as much as possible. Ensure that RF traces refer to a large-area ground plane, and run the RF traces on the surface as much as possible.

2) Do not route digital and analog signal lines across regions. If RF wiring must pass through the signal line, it is preferable to route a ground connected to the main ground along the RF wiring between them. Another option is to ensure that the RF wiring is connected to the main ground, crossing the signal line to reduce capacitive coupling. Put as much ground as possible around each RF trace and connect to the main ground. In general, RF printed lines should not be wired in parallel and should not be too long. If parallel wiring is necessary, a ground wire should be added between the two wires (the ground wire should be drilled through holes to ensure good grounding). For RF differential lines, run parallel lines and add ground lines outside the two parallel lines (ground lines are drilled through holes to ensure good grounding). The characteristic impedance of the printed lines should be designed according to the requirements of the device.

3) The basic sequence of RF printed circuit board wiring should be: RF line → baseband RF interface line (IQ line) → clock line → power supply part → digital baseband part → ground.

4) Green oil will impact the performance and signal of the microstrip line. It is recommended that microstrip lines with high frequency should not be coated with green oil, and the single board microstrip line with medium and low frequency is recommended to be coated with green oil.

5) RF traces are usually not punched. If RF traces must be changed, the size of the vias should be reduced to reduce path inductance and the chance of RF energy leaking to other areas in the laminate.

6) Duplexers, IF amplifiers, and mixers always have multiple RF/IF signals that interfere with each other. The RF and IF traces should be crossed as much as possible, and a ground should be spaced between them.

7) Except for special purposes, it is forbidden to protrude excess wire ends on the RF signal traces.

8) The wiring of the baseband RF interface line (IQ line) should be wider, more than 10mil, in order to avoid phase error. The line length should be as equal as possible, and the spacing should be as equal as possible.

9) The RF control line requires the wiring to be as short as possible. The wiring length is adjusted according to the input and output impedance of the transmission control signal device to reduce the introduction of noise. Keep traces away from RF signals, non-metallized vias, and “ground” edges. Do not drill ground vias around the traces to prevent signals from being coupled to the RF ground through the vias.

10) Keep digital wiring and power wiring away from RF circuits as much as possible. Clock circuits and high-frequency circuits are the main sources of interference and radiation and must be arranged separately and away from sensitive circuits.

11) The main clock wiring is required to be as short as possible. The line width is recommended to be more than 10mil, and the two sides of the trace are grounded to prevent interference from other signal lines. It is recommended to use stripline routing.

12) The control line of the voltage-controlled oscillator (VCO) must be kept away from the RF signal, and the VCO control line can be subjected to packet processing if necessary on the PCB board.

RF board PCB board layout principle

1) Layout determination: Prior to starting the layout, it is important to have a comprehensive understanding of the board’s function, working frequency band, current and voltage, main RF device types, EMC, and related RF indicators. It is also crucial to clarify the stack structure, impedance control, external structure size, shielding cavity and cover size and position, and special device processing instructions (e.g. size and position of devices that need to be hollowed out and directly dissipated by the chassis). Furthermore, the power, heat dissipation, gain, isolation, sensitivity of the main RF device and the connection of filtering, biasing, and matching circuits should be specified. The impedance matching circuit guidelines recommended in the device manual or obtained through RF field analysis software simulation should also be considered for the power amplifier circuit.

2) Physical partition: The main components should be arranged according to the flow direction of the single board’s main signal. First, position the components on the RF path according to the RF port location and adjust their orientation to minimize the length of the RF path. In addition to general layout rules, it is important to consider how to reduce mutual interference and increase the anti-interference ability of each part to ensure sufficient isolation of multiple circuits. For circuit modules with insufficient isolation or sensitive and strong radiation sources, the use of metal shields to block RF energy from the RF area should be considered.

3) Electrical partition: The layout is generally divided into three parts: power supply, digital, and analog, which must be separated in space. Layout and wiring should not cross these areas. Additionally, efforts should be made to separate strong and weak current signals, digital and analog signals, and to arrange circuits that complete the same function within a certain range to minimize the signal loop area.

RF board PCB board wiring principles

1) Always keep digital circuits away from analog circuits as much as possible. Ensure that RF traces refer to a large-area ground plane, and run the RF traces on the surface as much as possible.

2) Do not route digital and analog signal lines across regions. If RF wiring must pass through the signal line, it is preferable to route a ground connected to the main ground along the RF wiring between them. Another option is to ensure that the RF wiring is connected to the main ground, crossing the signal line to reduce capacitive coupling. Put as much ground as possible around each RF trace and connect to the main ground. In general, RF printed lines should not be wired in parallel and should not be too long. If parallel wiring is necessary, a ground wire should be added between the two wires (the ground wire should be drilled through holes to ensure good grounding). For RF differential lines, run parallel lines and add ground lines outside the two parallel lines (ground lines are drilled through holes to ensure good grounding). The characteristic impedance of the printed lines should be designed according to the requirements of the device.

3) The basic sequence of RF printed circuit board wiring should be: RF line → baseband RF interface line (IQ line) → clock line → power supply part → digital baseband part → ground.

4) Green oil will impact the performance and signal of the microstrip line. It is recommended that microstrip lines with high frequency should not be coated with green oil, and the single board microstrip line with medium and low frequency is recommended to be coated with green oil.

5) RF traces are usually not punched. If RF traces must be changed, the size of the vias should be reduced to reduce path inductance and the chance of RF energy leaking to other areas in the laminate.

6) Duplexers, IF amplifiers, and mixers always have multiple RF/IF signals that interfere with each other. The RF and IF traces should be crossed as much as possible, and a ground should be spaced between them.

7) Except for special purposes, it is forbidden to protrude excess wire ends on the RF signal traces.

8) The wiring of the baseband RF interface line (IQ line) should be wider, more than 10mil, in order to avoid phase error. The line length should be as equal as possible, and the spacing should be as equal as possible.

9) The RF control line requires the wiring to be as short as possible. The wiring length is adjusted according to the input and output impedance of the transmission control signal device to reduce the introduction of noise. Keep traces away from RF signals, non-metallized vias, and “ground” edges. Do not drill ground vias around the traces to prevent signals from being coupled to the RF ground through the vias.

10) Keep digital wiring and power wiring away from RF circuits as much as possible. Clock circuits and high-frequency circuits are the main sources of interference and radiation and must be arranged separately and away from sensitive circuits.

11) The main clock wiring is required to be as short as possible. The line width is recommended to be more than 10mil, and the two sides of the trace are grounded to prevent interference from other signal lines. It is recommended to use stripline routing.

12) The control line of the voltage-controlled oscillator (VCO) must be kept away from the RF signal, and the VCO control line can be subjected to packet processing if necessary on the PCB board.