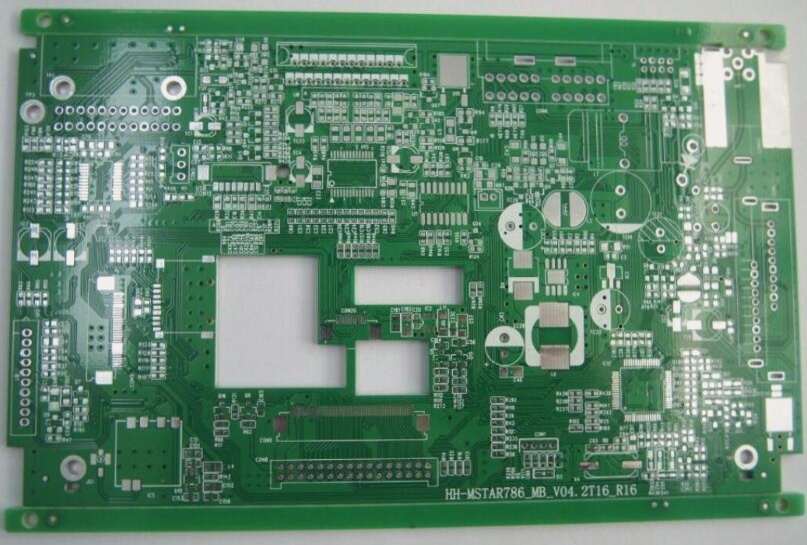

Printed Circuit Board Assembly (PCBA) Explained

From household lighting to aerospace devices, Printed Circuit Board Assembly (PCBA) is widely used in various industries. As a crucial component in electronic devices, mastering PCBA processes is essential for engineers and manufacturers. If you’re looking to enhance your understanding of PCB Assembly, keep reading.

Key Components of a Printed Circuit Board

- Copper layers

- Batteries

- Resistors

- LEDs

- Transistors

- Capacitors

- Inductors

- Diodes

- Switches

- Solder masks

- Silkscreens

A Printed Circuit Board (PCB) consists of these essential elements, with specific components varying based on requirements and surface area.

Types of Circuit Boards

Circuit boards are classified into three main types based on manufacturing processes and applications:

- Single-sided circuit board

- Double-sided circuit board

- Multilayered circuit board

PCB Assembly Process Overview

The PCB Assembly process involves several stages, including:

- Solder Paste Application

- Automated Component Placement

- Reflow Soldering

- Inspection

Applications of Printed Circuit Board Assembly

Printed Circuit Boards (PCBs) are utilized across various industries for:

- Medical devices

- LED lighting solutions

- Consumer electronics

- Automotive systems

- Aerospace technologies

- Safety and security devices

- Military and defense operations

Conclusion: Evolving PCB Assembly Technologies

PCB Assembly techniques, including Surface-Mount Technology (SMT) and Through-Hole Technology (THT), continue to advance, offering benefits such as high density, reduced size, and easy component insertion. Additionally, Box-Build Assembly integrates PCBs with other components for seamless electrical equipment operation.

For reliable PCB solutions tailored to your needs, contact us today to explore our cost-effective services and extensive industry experience.