The Importance of Rigid-Flex PCBs in Advancing 3D Printing Technology

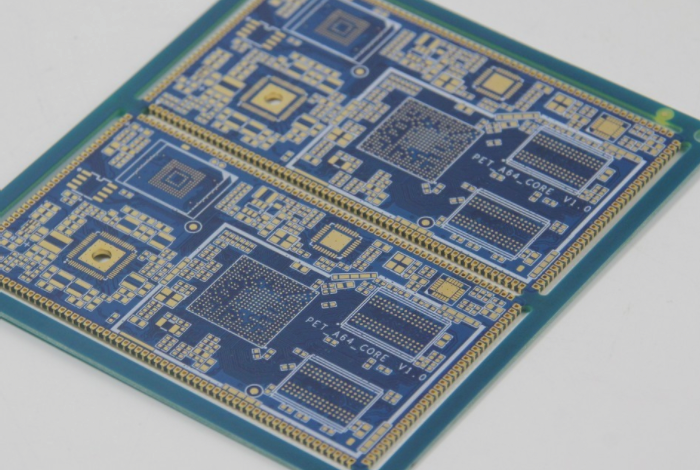

In the dynamic realm of 3D printing, achieving precise results is a top priority for enthusiasts and professionals alike. A key player in this arena is the rigid-flex printed circuit board (PCB). These innovative components are instrumental in elevating the performance, reliability, and precision of 3D printers.

Enhancing Structural Stability and Precision

Rigid-flex PCBs merge the strengths of rigid and flexible circuit technologies, featuring layers of both substrates to enable adaptable designs that suit various shapes and sizes. This unique construction is particularly advantageous in 3D printers, optimizing space utilization and ensuring seamless functionality for peak performance.

Improving Durability and Longevity

By integrating rigid and flexible elements into a single circuit, rigid-flex PCBs enhance the printer’s ability to withstand mechanical stresses and thermal changes. This durability translates to fewer malfunctions, prolonging the printer’s lifespan and minimizing downtime.

Streamlining Design and Efficiency

Rigid-flex PCBs reduce the overall weight and size of 3D printers by eliminating the need for complex wiring, harnesses, and connectors. This streamlined design not only enhances efficiency but also allows for more compact printer models, ideal for space-constrained environments.

Advancements in Signal Integrity and Thermal Management

Furthermore, rigid-flex PCBs play a crucial role in maintaining consistent signal paths, reducing noise, and interference in data transmission. This ensures quick and precise printer responses, ultimately enhancing print quality. Additionally, these PCBs aid in efficient heat dissipation, regulating component temperatures to prevent overheating and ensure printing precision.

Conclusion

Rigid-flex PCBs are pivotal in the evolution of 3D printing technology, offering benefits that include improved signal integrity, thermal management, and overall efficiency. By minimizing noise in data transmission and optimizing thermal conditions, these components contribute to a reliable, accurate, and effective 3D printing process.

Introduction

In the rapidly evolving 3D printing industry, the demand for precision, reliability, and performance is on the rise. Rigid-flex PCBs (Printed Circuit Boards) are crucial in meeting these increasing demands, enhancing the quality and functionality of 3D printers to meet the high standards expected by users.

Key Benefits of Rigid-Flex PCBs in 3D Printing

- Enhanced structural stability for consistent performance

- Improved signal integrity, reducing electrical interference

- Efficient thermal management to prevent overheating

- Compact design for space optimization without compromising performance

Future Prospects and Innovation

As the pursuit of precision in 3D printing advances, rigid-flex PCBs are set to play a pivotal role. Their ability to blend rigid and flexible designs positions them well to meet the changing needs of the industry. These PCBs are expected to drive further innovation in 3D printing, leading to faster, more reliable, and higher-quality machines.

Conclusion

Rigid-flex PCBs are indispensable in the continual progress of 3D printing. Whether you are a seasoned professional or new to the field, understanding the significance of these components offers valuable insights into the workings and capabilities of 3D printers. With rigid-flex PCBs at the forefront of innovation, they will continue to shape the future of 3D printing for years to come.