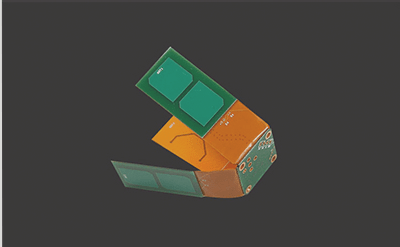

FPC Flexible Circuit Boards and Stiffeners: Enhancing Mechanical Strength

FPC flexible circuit boards are favored for their lightweight, thin, and compact design, making them ideal for smart electronic devices. However, their lower mechanical strength can lead to issues such as cracking when subjected to bending and abrasion.

Importance of Stiffeners

Stiffeners play a crucial role in enhancing the mechanical strength of FPC flexible circuit boards and simplifying component installation on the PCB surface. Various materials, including PET, PI, adhesive, metal, and resin-reinforced boards, are used as stiffeners.

Production Process

The production process of FPC flexible circuit board reinforcement boards involves cutting, drilling, black holes or PTH, adhering dry film, copper plating, etching, and more. Different types of reinforcement boards, such as hot-pressurized and pressure-sensitive boards, are utilized.

Pressing Process and Maturation

Hot-compressive and pressure-sensitive reinforcement boards are used in the pressing process, with maturation for hot-pressurized plates requiring high-temperature baking for complete aging. Equipment like refrigerators, laminating machines, and ovens are essential for PCB production.

Fixture and Reinforcement Materials

Introduction to FPC flexible circuit board fixtures, stiffener film reinforcement boards, adhesives, and release papers are crucial for enhancing the mechanical strength of the boards and facilitating surface mounting operations.

Storage Recommendations

It is recommended to store reinforcement plate films requiring refrigeration at temperatures between 1 and 9 degrees Celsius with a shelf life of 3 months. Flexible circuit board reinforcement materials should not be stored at room temperature for more than 8 hours.