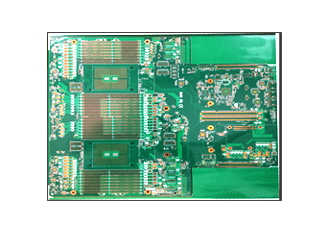

Number of layers: 16L, Board thickness: 2.36+/-0.22mm, Material: IT968G, Thickness-to-diameter ratio: 11.5:1, Impedance: 32 groups, Back drilling: 6 groups, Hole to trace: 0.175mm

Home » Shop » PCB Fabrication » 16-layer high-speed back drilling PCB

16-layer high-speed back drilling PCB

Product Details

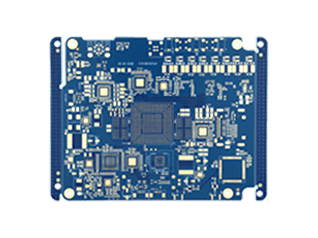

A 16-layer high-speed back-drilled PCB is a printed circuit board used in high-density, high-performance electronic devices. The back-drilling process in multi-layer PCBs is especially important as it helps optimize signal paths, reduce signal loss and interference, and improve overall signal integrity.

Lianmao IT968G is a commonly used high-speed PCB material known for its excellent electrical performance and mechanical stability, making it suitable for high-speed circuits. If your project requires a 16-layer high-speed back-drilled PCB and you wish to use Lianmao IT968G material, you should consult Qinlv Internation Co., Ltd. Wellcircuits PCB can provide this material and corresponding layer count PCB manufacturing, along with technical support services.

When designing a 16-layer high-speed back-drilled PCB, several key aspects need to be considered:

1. **Stacking Structure**

The stacking order and stacking thickness are crucial for controlling signal delay and reducing impedance variations.

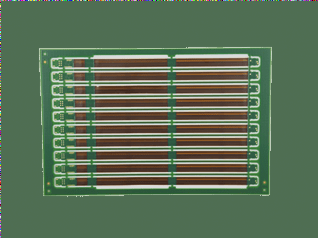

2. **Via Design**

The size, shape, and placement of vias need to be carefully planned to ensure optimal signal and power stability.

3. **Grounding and Shielding**

Effective grounding strategies and shielding techniques in multi-layer boards can significantly reduce noise and interference.

4. **Thermal Management**

High-speed circuits may lead to higher power consumption, so thermal design needs to be considered to maintain component stability.

To manufacture a 16-layer high-speed back-drilled PCB, you need to contact Wellcircuits PCB manufacturer. Wellcircuits PCB will provide a quote based on your design requirements and offer production services. When choosing a manufacturer, Wellcircuits PCB fully meets customer needs in terms of technical expertise, production equipment, quality control, delivery time, and pricing.

SKU: bc55515ad44e Categories: IOT & IIOT PCB, PCB Fabrication, Rigid PCB Tags: flex pcb, gerber viewer, PCBA, RF PCB

IOT & IIOT PCB, PCB Fabrication, Rigid PCB