Flex PCB Prototype Manufacturer | Quick-turn Flexible PCB Prototyping

| Stock Material for flexible PCB | Dielectric Thickness | Copper Thickness |

|---|---|---|

| Measure | mil | μm (oz/ft2) |

Adhesiveless Flexible Laminates | 1mil/2mil/3mil/4mil | 1/3oz, 1/2oz, 1oz, 2oz |

| 2mil/3mil/4mil/5mil | 1/3oz, 1/2oz, 1oz, 2oz | |

all polyimide laminate | 4.0 / 3.0/ 2.0 | 18 (0.5) |

all polyimide laminate | 3.0/ 4.0 | 35 (1.0) |

Dk 2.9 Df 0.002 @14GHz | 1/2/3/4/5 | 1/2oz, 1/3oz, 1/4oz |

Flex PCB Prototype

We have completed over 800+ flexible PCB prototyping projects for customers around the world, across various industries. Among these orders, 2/4/6/8/10 layers are the structure we mainly fabricate. Below are some examples :

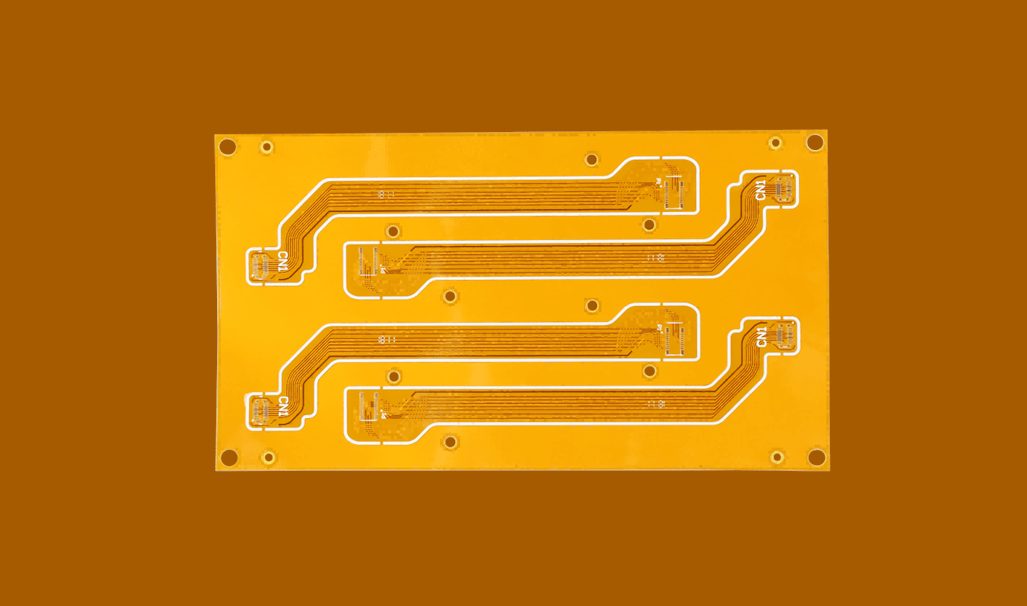

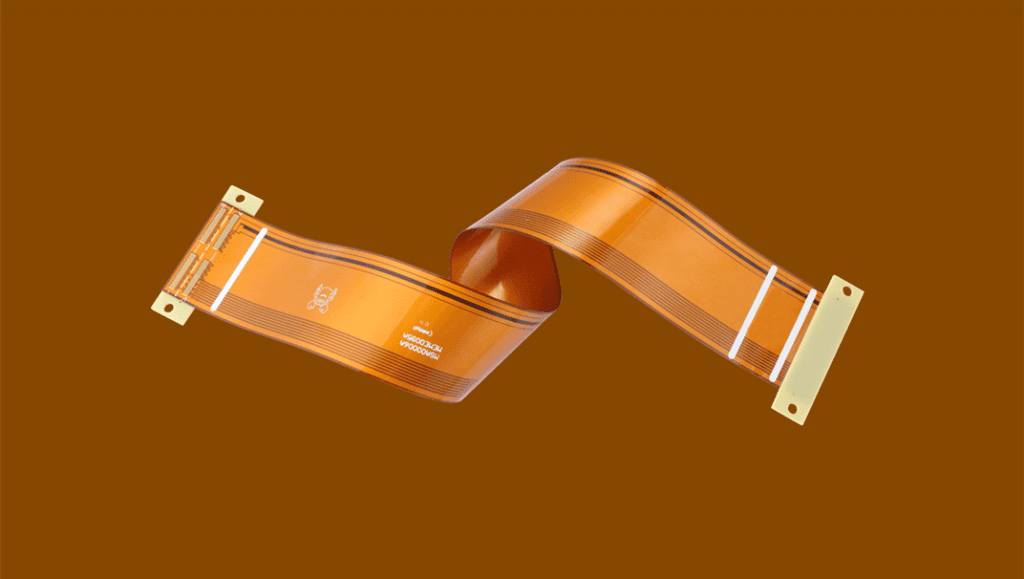

2 Layer Flex PCB Prototype

Double-sided FPC is the most common structure, widely used as interconnection technology to replace soldered flex cables.

Flex PCB at the right is the typical 2L FPC with connectors assembled at both ends to interconnect rigid PCB.

It comes with 130mm x 32mm size, 4mil/4mil min trace/width and FR-4 stiffeners to support connectors soldering.

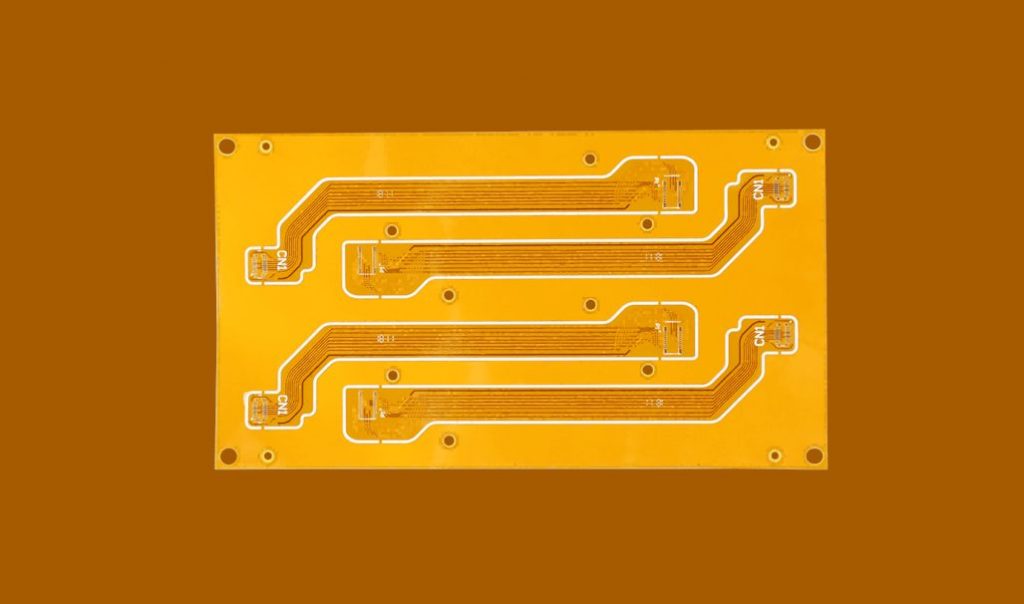

4 Layer Flex PCB Prototype

This 4L flexible PCB is manufactured for vehicle communication applications, featuring 100OHM differential pairs and EMI shielding.

The single pc size is 98mm x 12mm. Min trace/space: 4mil/4mil. ENIG treatment.

To prevent EMI disrupting the performance of an electrical circuit, we recommend to apply EMI shielding foil after coverlay.

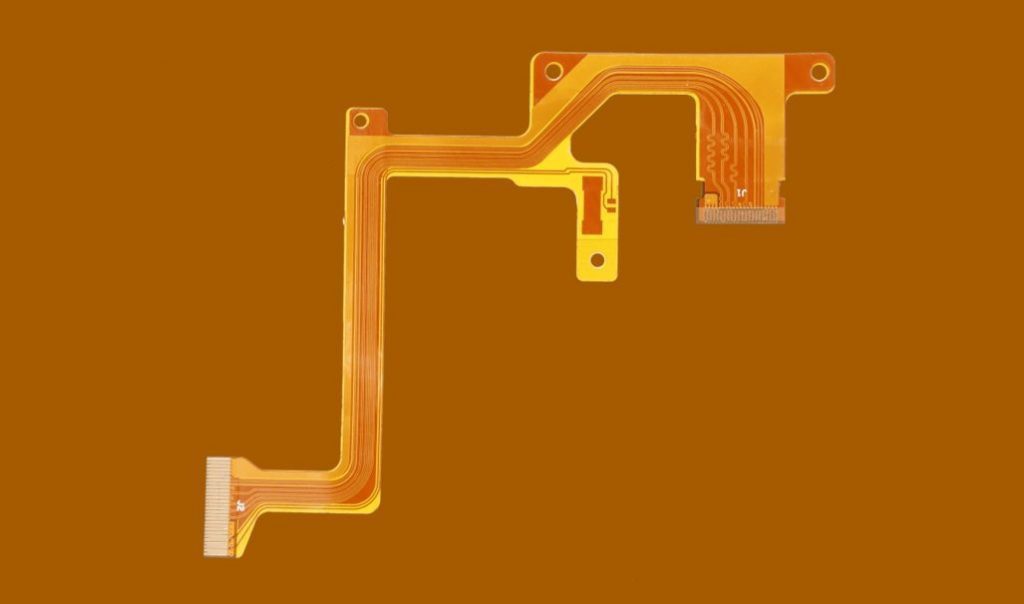

8 Layer Flex PCB Prototype

8 layer is a high layer count for the flexible printed circuit board. A higher layer means a higher possibility of occurring deformation, which will make vias drilling and lamination process harder to control.

That is why few PCB manufacturers are able to mass produce high-layer FPC with consistent quality.

Get Instant Quote Now

Our Flexible Circuit Capability

Flexible Circuit's - Technical Capability

| Item | Specification | ||||

|---|---|---|---|---|---|

| Layer | >=1 | ||||

| Max Size | 20"x40",support customization | ||||

| Substrate | Polyimide; LCP | ||||

| Final Thickness | 0.12-0.4 mm ,support customization | ||||

| Min Trace/Space | 2mil/2mil | ||||

| Via Types | Through vias; Tented vias; Blind vias; Buried vias; Stacked vias; Via in pad | ||||

| Copper Weight(finished) | 25-140um | ||||

| Min Laser Via | 3mil | ||||

| Min Mechanical Hole | 4mil | ||||

| Impedance Control | YES | ||||

| Stifferner Material | FR-4, Polyimide, SUS | ||||

| Surface Finishes | LF HASL, OSP, ENIG, Immersion tin, Gold fingers | ||||

| Available Service | Bare Board Production; Consigned Assembly; Turnkey Assembly | ||||

XPCB ADVANTAGES

- In-house engineering

- Turnkey FPC & Assembly Solution

- Quick-turn up to 48hrs

- In-house assembly lines

- Support Prototype | Series Production

Get Instant Quote Now

TOGETHER, Build Your Flex PCB One-time Success

WellCircuits is a decade-old flex PCB manufacturer & assembler in China. With more than 15 years of experience as a PCB supplier, we are known for our expertise in flex PCB manufacturing & assembly, including flex PCB prototypes, low volume, medium volume, and high volume flexible PCB. Meanwhile, we also provide a one-stop flex PCB assembly service for customers who need affordable and quick turnaround PCBA service.

All of our flex PCB products are IPC standard certified with Class II or Class III as customer needs. It’s our goal to provide top-notch flex PCBs to the department dedicated to electronics development. Whether you are a design company or end product manufacturer, we are more than happy to offer you our professional flex PCB solution.

To maximize the odds of “Right at First Design”, we can provide in-depth engineering support for each stage, from layout drawing, mechanical assemblies, and functions testing to prototype return result analysis and refinement trial. Using our decade of flex PCB manufacturing experience, you can avoid multiple manufacturability & compatibility issues before going to scale production.

Our typical lead time for flex PCB prototype is 2-12 working days. If adding components assembly, lead time would be extended to 14 working days. To check quote, we usually need following info:

1.Gerber file 2.BOM (if need assembly) 3. Qty 4. Manufacturing Instructions