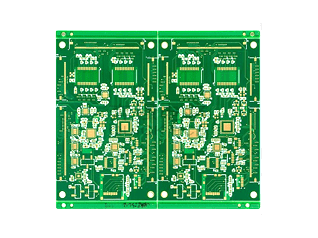

The production and processing of automotive display board PCBs involve many technical requirements due to the special nature of the automotive environment, which demands that PCBs must have high reliability and durability. Here are some of the main technical challenges:

High-temperature tolerance: Automotive PCBs need to withstand a wide range of temperatures, from extreme heat to cold, which requires the materials and processes used to adapt to such temperature changes without affecting performance.

Vibration and impact resistance: Vehicles generate vibrations and impacts during operation, and PCBs must be able to withstand these mechanical stresses without damage or affecting electrical connections.

Corrosion and moisture resistance: The interior of a car may contain corrosive gases and moisture, so PCBs require good corrosion and moisture resistance, which necessitates taking special protective measures in design and manufacturing.

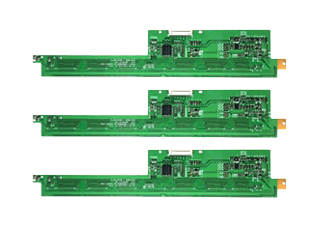

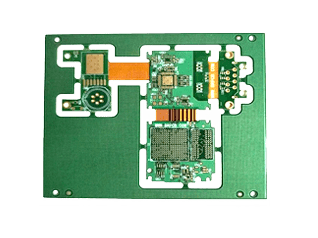

High density and refinement: With the trend towards miniaturization of automotive electronic devices, PCBs also need to be increasingly dense and refined, which requires higher precision and finer processes in manufacturing.

Electromagnetic compatibility (EMC): Automotive electronic devices need to coexist with other devices in a limited space, so PCB design must consider electromagnetic compatibility to avoid interference or being interfered with.

Traceability and maintainability: To ensure product quality and safety, automotive PCBs need to have good traceability and should be easy to repair and replace parts.

Environmental requirements: With the increasing awareness of environmental protection, PCB production needs to comply with strict environmental protection standards and regulations, such as RoHS and REACH.

Rapid and mass production: The automotive manufacturing industry requires efficient production lines, and PCB manufacturers need to have the ability to produce on a large scale and quickly to meet delivery times.

To overcome these technical challenges, PCB manufacturers usually need to invest a lot of R&D resources, adopt advanced production equipment and processes, and implement strict quality control systems. In addition, close cooperation with automotive manufacturers and understanding specific application scenarios and requirements is also crucial.

Get Instant Quote Now

WellCircuits ADVANTAGES

- In-house engineering

- Turnkey FPC & Assembly Solution

- Quick-turn up to 48hrs

- In-house assembly lines

- Support Prototype | Series Production