What is Rigid-flex PCB?

Rigid-flex circuits and assemblies are a unique combination of rigid and flexible substrates fused into a single structure. They merge the attributes of a PCB with the benefits of flexible printed circuit (FPC) technology. These boards usually consist of multiple conductive layers, incorporating both flexible and rigid insulation materials. The rigid layers contain conductors, while both rigid and flexible layers feature plated through-holes. This construction allows for versatile design possibilities with elements like exposed pads or covers on the outer layers.

What Advantages Rigid-flex PCB has?

Rigid-flex circuits and assemblies are a fusion of rigid and flexible substrates, creating a singular structure. They combine PCB features with the advantages of flexible printed circuit (FPC) technology. These boards usually consist of multiple conductive layers, incorporating flexible or rigid insulation materials between them. The outer layers might feature exposed pads or covers. Rigid layers host conductors, while both rigid and flexible layers have plated through-holes.

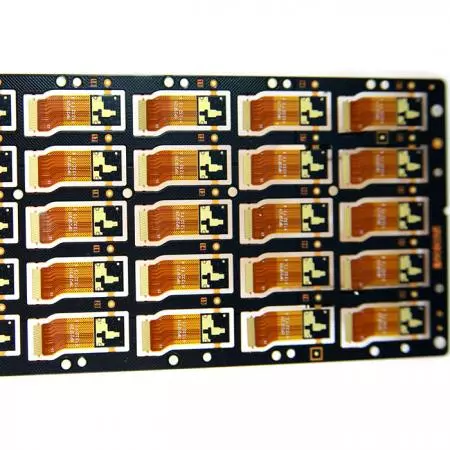

Reliable Rigid-flex PCB Solution

So far, WellCircuits has served numerous clients from diverse sector such as medical, telecommunications and manufacturing with our superior quality Rigid-flex PCB manufacturing services. We have an in-house quality control department to ensure your boards fabricated and assembled properly.

Our extensive experience in Rigid-flex PCB fabrication and advanced equipments enable us to meet various customization requirements as regards all PCB specs, like

- Base material

- Rolled or annealed copper

- Adhesive or adhesiveless core

- Coverlay or soldermask

- Static or dynamic flex

- Coating

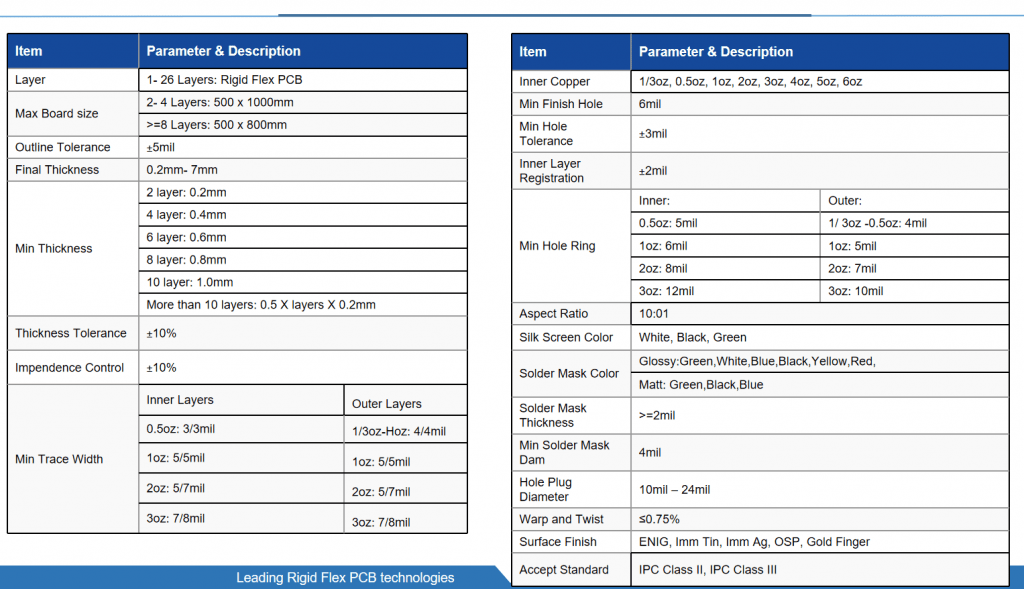

Here is our powerful Rigid-flex capability sheet:

Here is our powerful Rigid-flex capability sheet:

Why Choose WellCircuits For Your Rigid flex PCB Project?

WellCircuits, a prominent PCB manufacturer in China, boasts over a decade of expertise in PCB fabrication, particularly excelling in rigid-flex PCB production. Our highly trained engineering team conducts thorough Design for Manufacturability (DFM) checks before the manufacturing phase. This seamless service, spanning from design verification to meticulous procedure control, has enabled us to achieve a remarkable on-time delivery rate of up to 99% with an impressively low rejection rate of 1% for our rigid-flex PCBs. To begin, kindly complete the inquiry form below.

Get Instant Quote Now

WellCircuits ADVANTAGES

- In-house engineering

- Turnkey FPC & Assembly Solution

- Quick-turn up to 48hrs

- In-house assembly lines

- Support Prototype | Series Production

Reviews

There are no reviews yet.