Rogers Corporation (NYSE:ROG) is a global technology leader in engineered materials to power, protect, and connect our world. With more than 180 years of materials science experience, Rogers delivers high-performance solutions that enable clean energy, Internet connectivity, advanced transportation, and other technologies where reliability is critical.

In high-frequency PCB production, Rogers laminate is the most popular choice by engineers owing to its low Dk/Low loss comes in various dielectric thicknesses.

Below are popular Roger laminate materials:

RT 5870 & 5880 Laminate

RT/duroid 5870 and 5880 laminates have a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain the Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Features

- Dk or 2.20 +/- .02

- Dissipation factor of .0009 at 10GHz

- Low moisture absorption

- Isotropic

RT 5870 & 5880 Laminate

RO4835 laminates are a low loss material that offer low cost circuit fabrication, compatible with standard epoxy/glass (FR-4) processes. These laminates are available with Rogers proprietary LoPro® Reverse treated copper foil, ideal for applications requiring low insertion loss.

Features

- RoHS compliant for applications requiring UL 94 V-0

- IPC-4103 compliant

- Dielectric constant (Dk) of 3.48 +/- .05

- Dissipation factor of 0.0037 at 10 GHz

- Isotropic

RO3000 Laminate

RO3000 Series laminates are circuit materials with consistent mechanical properties, regardless of the dielectric constant (Dk) selected. This allows the designer to develop multi-layer board designs that use different dielectric constant materials for individual layers, without encountering war-page or reliability problems. Additionally, the RO3000 series’ dielectric constant is stable over a wide temperature range.

Benefits

- Lowest loss commercial laminates

- Available in a wide range of Dk (3.0 to 10.2)

- Available both with and without woven glass reinforcements

- Low Z-axis CTE provides plated through-hole reliability

RT6202 Laminate

RT/duroid 6202 high frequency laminates offer electrical and mechanical properties essential in designing complex microwave structures that are mechanically reliable and electrically stable. Excellent dimensional stability (0.05 to 0.07 mils/inch) is achieved by the addition of limited woven glass reinforcement. This often eliminates double etching to achieve tight positional tolerances.

Features

- Dielectric constant (Dk) of 2.90 +/- .04

- Low dissipation factor of .0015 at 10GHz

- Low thermal coefficient of Dk at 5 ppm/°C

- Tight thickness control

Benefits

- Low loss for excellent high frequency performance

- Isotropic

TC600 Laminate

TC600 laminates best-in-class thermal conductivity and mechanical robustness enable printed circuit board (PCB) size reduction. The increased thermal conductivity provides higher power handling, reduces hot-spots and improves device reliability. Features

- Dielectric constant (Dk) of 6.15

- High thermal conductivity of 1.0W/mK

- Stable Dk across wide temperature range of -75ppm/°C from -40°C to 140°C

- Low loss tangent of .002 at 10 GHz

- Low coefficient of thermal expansion on X,Y and Z axis (9, 9 and 35 ppm/°C)

RT6035 Laminate

RT/duroid 6035HTC laminates are an exceptional choice for high power applications. The laminates have a thermal conductivity of almost 2.4 times the standard RT/duroid 6000 products, and copper foil (ED and reverse treat) with excellent long term thermal stability. Additionally, Rogers advanced filler system enables excellent drill-ability, reducing drilling costs as compared to standard high thermally conductive laminates that use alumina fillers.

Features

- Dielectric constant of 3.50 +/- .05

- Dissipation factor of .0013 at 10GHz

- Thermal conductivity of 1.44 W/m/K at 80°C

- Thermally stable low profile and reverse treat copper foilTC600 Laminate

- Isotropic

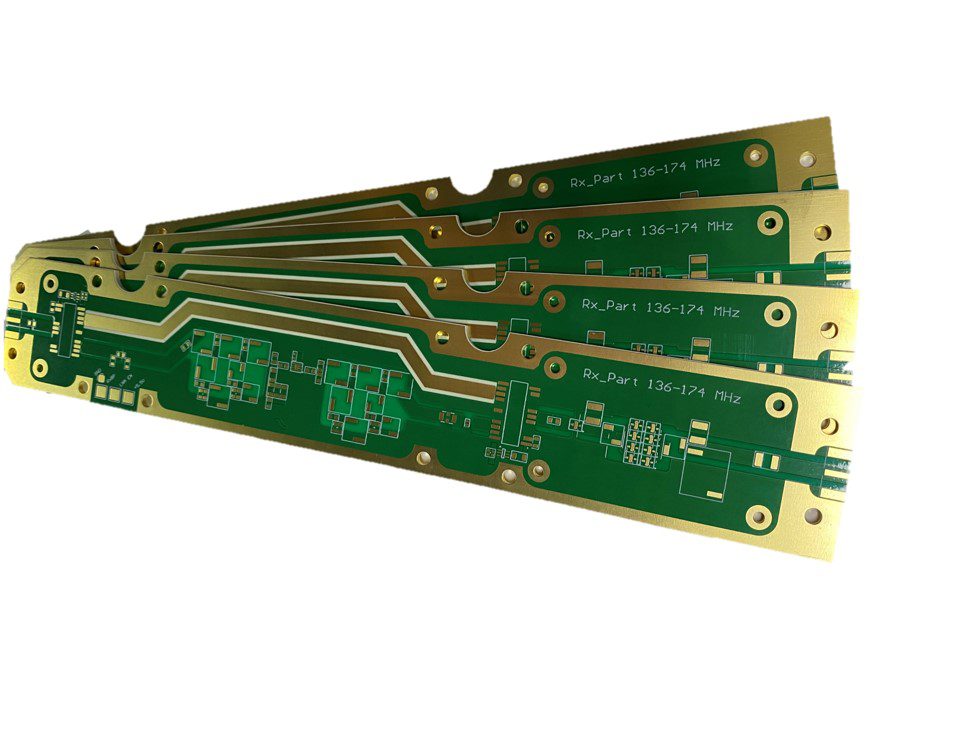

At WellCircuits, we fabricate best-in-class Roger PCB with rogers laminate material. Because of low loss, stable Dk, and high thermal requirements for Rogers PCB product, we put in extra care in each step of making rogers PCB. AOI and visual inspection are strictly implemented by skillful staffs before shipment. Professional CoC report will be provided for the customer’s review. If you are looking Rogers PCB fabrication and assembly service, you are now in one of the best hand, upload your Gerber file below now to get instant quote!

Get Instant Quote Now

WellCircuits ADVANTAGES

- In-house engineering

- Turnkey FPC & Assembly Solution

- Quick-turn up to 48hrs

- In-house assembly lines

- Support Prototype | Series Production

Reviews

There are no reviews yet.