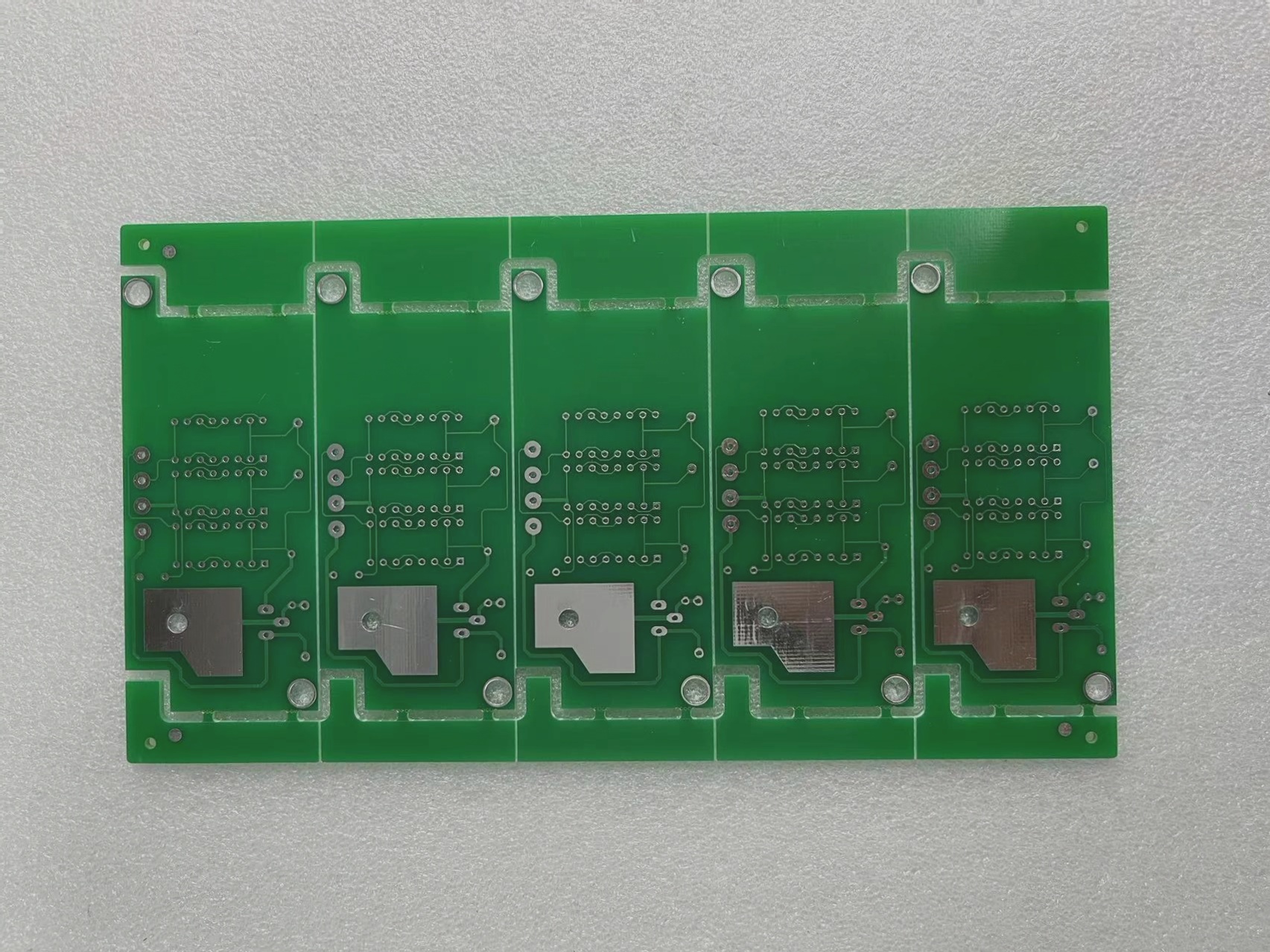

1. Simulated back welding

Generally, the downstream PCBA assembly process has about five stages of heating, including:

(1) Printing of solder paste and dispensing on the front, followed by hot-air soldering.

(2) Flipping the board over and performing back soldering with solder paste.

(3) Wave soldering of pin parts.

(4) Potential 1-2 times of rework and repair soldering.

Therefore, most assembly manufacturers require that the empty boards from FR4 plate manufacturers undergo more than five simulated reflows according to a specific reflow curve, as a reference standard for their ability to withstand intense heat. However, even if the blank multilayer boards can pass the test of five simulated back welds, it is still difficult to ensure the safety of the assembler during back welding operations, and there may still be a certain rate of board bursting during actual installation. This is mainly due to the additional stress from the components on the board.

FR4 Plate

The upwind temperature of the hot-air back-welding furnace is usually about 50-60 ℃ higher than the downwind temperature of the plate. The purpose of the downwind is to maintain the basic heat of the plate, and it is not necessary to maintain the same heat with the upwind at all, in order to avoid unnecessary energy waste and damage to the plate. Additionally, when the reverse side is welded for the second time, it can also reduce the strong heat injury to the person who has been welded on the first side and the possibility of falling parts. However, these differences in heat between the upper and lower plates will inevitably lead to differences in thermal expansion of both sides of the FR4 plate, resulting in a slight humped arc bulge of the plate surface during back welding. This can lead to tensile stress between the compact assembly and the FR4 PCB. Furthermore, the huge heat obtained by integrating the reflow temperature and time has not only far exceeded the Tg of the plate, but also transitioned the plate from a glass state lower than Tg α-1 to a soft rubber state higher than Tg α-2. At this point, if there is a lot of local stress, it will cause blistering and bursting from the surface of the thick multilayer plate.

The Weakness of the Rubber Knee of the Plate

When the board is equipped with several large BGA or QFN front temples, the thermal expansion rate (CTE) of the chips inside the board is only 3-4 ppm/℃, which will force the thermal expansion rate of X and Y axes to 15 ppm/℃. This will cause the carrier plate of the FR4 plate to be pulled up and warped during back welding. The upward warping of these carrier plates and the downward bending of the FR4 PCB motherboard will inevitably damage the solder joint and the expanded plate if they are pulled against each other. There is an unwritten heating principle for plates, that is, the resin would double the energy of reaction when the temperature was raised by 10 ℃, and the volume and mass were the largest in the process of hot-air reflow. The degree of heating is also much higher than that of various components on the board. In fact, the FR-4 plate is below Tg α in the glass state, CTE of the Z axis is up to 55-60 ppm/℃, which is far more than 14-15 pm/℃ in the X and Y directions clamped by the glass fiber cloth. Once in α-2, in the rubber state, the CTE of its Z axis is higher than 250 pm/℃, and any local uneven stress on the plate surface may cause blistering or bursting of the outer layer.

Location and Cause of Easily Exploded Plate

1) Large Copper Surface Area of Inner Layer

Because the thermal expansion coefficient (CTE) of copper (CTE is only 17pm/℃) and resin Z direction is too far away, the large copper surface area is easy to explode in strong heat. The solution is to deliberately arrange a few non-functional through-holes in the large copper area as rivets, which can help heat dissipation and reduce the explosion disaster of multi-layer thick plates. However, the quality of PTH hole copper must be good enough, and its elongation should be controlled above 20% to make sense. In the future, under the pressure of the prevalence of lead-free soldering, the minimum specification of elongation will rise to 20%. There are still many suppliers whose quality is far behind the current requirements for thick plates. Of course, the management of the on-site copper plating bath and the inspection of the hole copper quality of the FR4 PCB should not be sloppy, to reduce the expansion and cracking of the plate in the lead-free reflow. In the event of plate bursting in the large copper surface area, it can be clear whether the crack is caused by the blackening layer of the copper foil through a detailed examination.

2) Through-hole Dense Area

For example, if the ball pad and the dense through-holes connected with the inner layer of the belly bottom of the large BGA are not blocked before back-welding, a large amount of heat energy from the downwind will enter into the air, causing the heat from the upper and lower parts to be added and difficult to dissipate. This may cause local plate explosion during the double suffering. In addition, when the plate is turned over for secondary re-welding, it may also cause the remelting or strength reduction of the previous solder joint. As for multi-pin connectors, it will bring extra stress and is prone to burst, which is also a very difficult problem. Blocking these holes with green paint to isolate the hot air is a challenging task, and the use of special resin as filler is too expensive for general circuit board manufacturers.

3) Local Blisters of Outer Layer

The heating rate and heat of the outer layer in the back-welding must be much higher than the inner core plate. Therefore, if the back-welding furnace is not ideal, or its back-welding curve still continues the old and improper lead-containing practice, it will inevitably lead to a considerable number of bursting plates. Most of these local outer blisters are near the large BGA or QFN, especially the low and legless QFN. Other areas with dense through-holes such as edges and corners of plates are also high-risk areas.

4) Multiple Plate Bursts Due to Repeated Strong Heat

Lead-free soldering of FR4 PCB will continue the previous practice, mainly by double-sided SMT solder paste reflow, plus a transmission wave soldering or partial selective surge soldering. If the multilayer board is placed for too long, resulting in the accumulation of stress energy, or if it is not baked after pressing to eliminate the stress, the CTE differences between the plate members and other members will gradually emerge and the stress release behavior will occur. Baking before reflow can reduce the occurrence of plate bursting. If there is other strong heat after the above three conventional welding, it may cause plate explosion, and the operator cannot handle it carelessly. According to the long-term experience of the production line, the damage of lead-free reflow to multilayer plates is about 2-3 times more than that of lead-free wave soldering. Therefore, manual soldering should be used as far as possible to replace the reflow and wave soldering to reduce the occurrence of plate bursting.

Generally, the downstream PCBA assembly process has about five stages of heating, including:

(1) Printing of solder paste and dispensing on the front, followed by hot-air soldering.

(2) Flipping the board over and performing back soldering with solder paste.

(3) Wave soldering of pin parts.

(4) Potential 1-2 times of rework and repair soldering.

Therefore, most assembly manufacturers require that the empty boards from FR4 plate manufacturers undergo more than five simulated reflows according to a specific reflow curve, as a reference standard for their ability to withstand intense heat. However, even if the blank multilayer boards can pass the test of five simulated back welds, it is still difficult to ensure the safety of the assembler during back welding operations, and there may still be a certain rate of board bursting during actual installation. This is mainly due to the additional stress from the components on the board.

FR4 Plate

The upwind temperature of the hot-air back-welding furnace is usually about 50-60 ℃ higher than the downwind temperature of the plate. The purpose of the downwind is to maintain the basic heat of the plate, and it is not necessary to maintain the same heat with the upwind at all, in order to avoid unnecessary energy waste and damage to the plate. Additionally, when the reverse side is welded for the second time, it can also reduce the strong heat injury to the person who has been welded on the first side and the possibility of falling parts. However, these differences in heat between the upper and lower plates will inevitably lead to differences in thermal expansion of both sides of the FR4 plate, resulting in a slight humped arc bulge of the plate surface during back welding. This can lead to tensile stress between the compact assembly and the FR4 PCB. Furthermore, the huge heat obtained by integrating the reflow temperature and time has not only far exceeded the Tg of the plate, but also transitioned the plate from a glass state lower than Tg α-1 to a soft rubber state higher than Tg α-2. At this point, if there is a lot of local stress, it will cause blistering and bursting from the surface of the thick multilayer plate.

The Weakness of the Rubber Knee of the Plate

When the board is equipped with several large BGA or QFN front temples, the thermal expansion rate (CTE) of the chips inside the board is only 3-4 ppm/℃, which will force the thermal expansion rate of X and Y axes to 15 ppm/℃. This will cause the carrier plate of the FR4 plate to be pulled up and warped during back welding. The upward warping of these carrier plates and the downward bending of the FR4 PCB motherboard will inevitably damage the solder joint and the expanded plate if they are pulled against each other. There is an unwritten heating principle for plates, that is, the resin would double the energy of reaction when the temperature was raised by 10 ℃, and the volume and mass were the largest in the process of hot-air reflow. The degree of heating is also much higher than that of various components on the board. In fact, the FR-4 plate is below Tg α in the glass state, CTE of the Z axis is up to 55-60 ppm/℃, which is far more than 14-15 pm/℃ in the X and Y directions clamped by the glass fiber cloth. Once in α-2, in the rubber state, the CTE of its Z axis is higher than 250 pm/℃, and any local uneven stress on the plate surface may cause blistering or bursting of the outer layer.

Location and Cause of Easily Exploded Plate

1) Large Copper Surface Area of Inner Layer

Because the thermal expansion coefficient (CTE) of copper (CTE is only 17pm/℃) and resin Z direction is too far away, the large copper surface area is easy to explode in strong heat. The solution is to deliberately arrange a few non-functional through-holes in the large copper area as rivets, which can help heat dissipation and reduce the explosion disaster of multi-layer thick plates. However, the quality of PTH hole copper must be good enough, and its elongation should be controlled above 20% to make sense. In the future, under the pressure of the prevalence of lead-free soldering, the minimum specification of elongation will rise to 20%. There are still many suppliers whose quality is far behind the current requirements for thick plates. Of course, the management of the on-site copper plating bath and the inspection of the hole copper quality of the FR4 PCB should not be sloppy, to reduce the expansion and cracking of the plate in the lead-free reflow. In the event of plate bursting in the large copper surface area, it can be clear whether the crack is caused by the blackening layer of the copper foil through a detailed examination.

2) Through-hole Dense Area

For example, if the ball pad and the dense through-holes connected with the inner layer of the belly bottom of the large BGA are not blocked before back-welding, a large amount of heat energy from the downwind will enter into the air, causing the heat from the upper and lower parts to be added and difficult to dissipate. This may cause local plate explosion during the double suffering. In addition, when the plate is turned over for secondary re-welding, it may also cause the remelting or strength reduction of the previous solder joint. As for multi-pin connectors, it will bring extra stress and is prone to burst, which is also a very difficult problem. Blocking these holes with green paint to isolate the hot air is a challenging task, and the use of special resin as filler is too expensive for general circuit board manufacturers.

3) Local Blisters of Outer Layer

The heating rate and heat of the outer layer in the back-welding must be much higher than the inner core plate. Therefore, if the back-welding furnace is not ideal, or its back-welding curve still continues the old and improper lead-containing practice, it will inevitably lead to a considerable number of bursting plates. Most of these local outer blisters are near the large BGA or QFN, especially the low and legless QFN. Other areas with dense through-holes such as edges and corners of plates are also high-risk areas.

4) Multiple Plate Bursts Due to Repeated Strong Heat

Lead-free soldering of FR4 PCB will continue the previous practice, mainly by double-sided SMT solder paste reflow, plus a transmission wave soldering or partial selective surge soldering. If the multilayer board is placed for too long, resulting in the accumulation of stress energy, or if it is not baked after pressing to eliminate the stress, the CTE differences between the plate members and other members will gradually emerge and the stress release behavior will occur. Baking before reflow can reduce the occurrence of plate bursting. If there is other strong heat after the above three conventional welding, it may cause plate explosion, and the operator cannot handle it carelessly. According to the long-term experience of the production line, the damage of lead-free reflow to multilayer plates is about 2-3 times more than that of lead-free wave soldering. Therefore, manual soldering should be used as far as possible to replace the reflow and wave soldering to reduce the occurrence of plate bursting.