Inspections of Flexible Printed Circuit Boards (FPC)

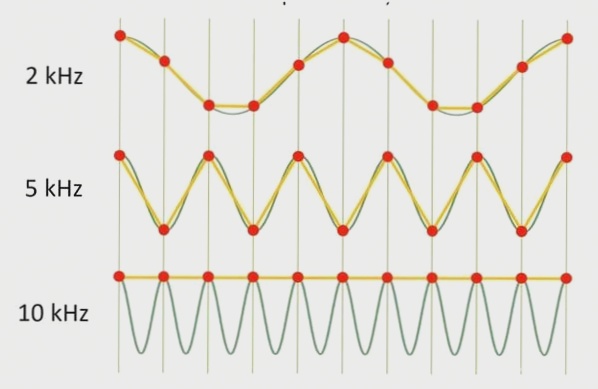

1. With the increasing circuit density, inspections of flexible printed circuit boards (FPC) require higher magnification microscopes, leading to longer inspection times. The need for man-hours in inspecting FPCs is significant and continues to grow with advancements in circuit density. Despite efforts to reduce defect rates, the pass rate for precision pattern circuits may not see substantial improvements.

2. Not all inspection items for FPCs are conducted at the final stage; defects related to circuits and coverage are better identified during the manufacturing process. In-process inspections, while not replacing final inspections entirely, contribute to enhancing overall production efficiency.

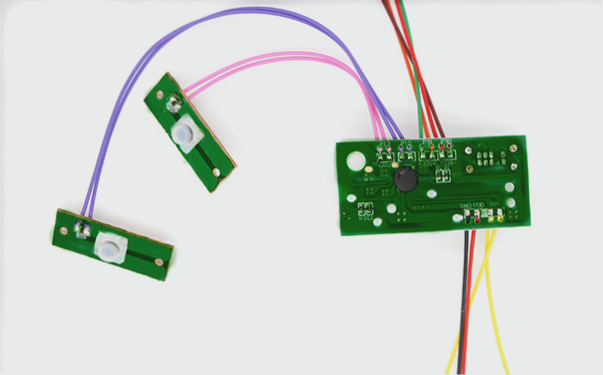

Processing of FPC Reinforced Boards

1. FPC reinforced board processing involves using film-like adhesives protected by release films on both sides. The dimensional accuracy of the reinforcement board may vary based on the materials used. Automated processing of film-like reinforcing plates can reduce manufacturing costs.

2. Aligning and positioning the reinforcement board onto the FPC with processed shapes and holes is a manual operation that significantly impacts processing costs. Simple designs and user-friendly jigs can enhance production efficiency and reduce costs.

Bonding Methods for Reinforced Boards

1. There are two bonding types for reinforced boards: pressure-sensitive (PSA) and thermosetting adhesives, each requiring different levels of labor for processing. Pressure-sensitive bonding is straightforward and requires applying pressure for a short time to achieve the required bonding strength.

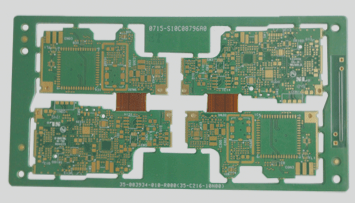

Thermosetting Adhesives in PCB Manufacturing

When it comes to PCB manufacturing, the use of thermosetting adhesives plays a crucial role. These adhesives require specific conditions for bonding, such as a pressure of 3–5 MPa (30–50 kg/cm²) and high temperatures ranging from 160 to 180 degrees Celsius. Maintaining these conditions for 30–60 minutes is essential for a successful bond.

It is important to apply uniform pressure on the reinforced board to prevent any stress on the flexible printed board. Uneven pressure distribution can result in breakage at the ends of the reinforced board, impacting the overall quality of the PCB.

For more advanced applications, double-sided adhesive films with release films on both sides are used to bond flexible printed boards or flexible printed boards to rigid ones. This process effectively creates a composite structure similar to half a rigid printed board. The processing and curing steps for this method closely resemble those used in the lamination process for reinforced boards.

If you are in need of PCB manufacturing services or have any inquiries, feel free to contact us for assistance.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย