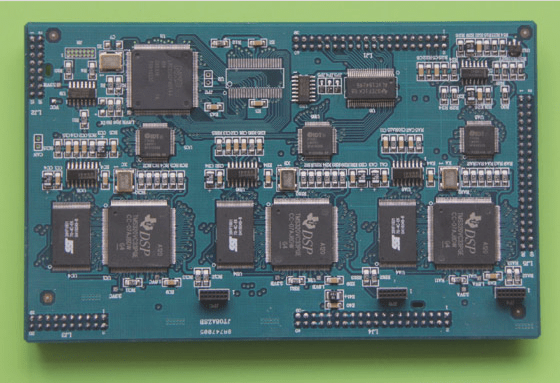

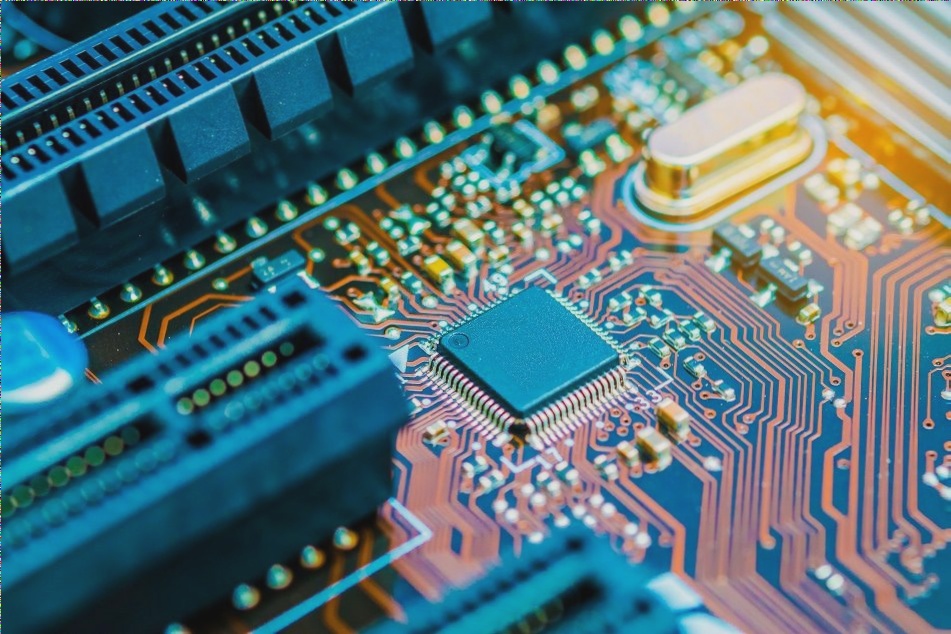

Properties and uses of copper plating:

The copper plating layer of a PCB board is a beautiful rosy color, soft, malleable, easy to polish, and has good thermal and electrical conductivity. However, it is prone to oxidation in the air and quickly loses its luster, making it unsuitable as a surface layer for protective-decorative coatings.

Copper plating is primarily used as the bottom layer in multi-layer plating of steel parts, and it is also commonly used as the base layer in tin plating, gold plating, and silver plating. Its main function is to enhance the bonding strength between the base metal and the surface or intermediate coating, facilitating the deposition of the surface coating. A non-porous copper plating layer can improve the corrosion resistance of the surface plating layer. For instance, the thick copper and thin nickel plating process in protective-decorative multilayer plating can help save precious nickel metal.

The properties and uses of nickel plating:

Nickel metal exhibits strong passivation ability, quickly forming a thin passivation film on the part’s surface that resists atmospheric corrosion and certain acids, giving nickel coatings excellent stability in the air. In a simple nickel salt electrolyte, a very fine crystalline coating can be achieved with outstanding polishing characteristics. Polished nickel coatings maintain a mirror-like luster for an extended period in atmospheric conditions and also offer high hardness and wear resistance.

Based on the characteristics of nickel plating, it is commonly employed as the bottom layer, middle layer, and surface layer in protective-decorative plating applications such as nickel-chromium plating, nickel-copper-nickel-chromium plating, copper-nickel-chromium plating, and copper-nickel plating.

Due to the high porosity of nickel plating, it only becomes non-porous when the plating layer thickness exceeds 25μm. Therefore, nickel plating layers are typically not utilized as protective plating layers.

The production of nickel plating is substantial, with about 10% of the world’s total nickel production being consumed by nickel plating processes.

The copper plating layer of a PCB board is a beautiful rosy color, soft, malleable, easy to polish, and has good thermal and electrical conductivity. However, it is prone to oxidation in the air and quickly loses its luster, making it unsuitable as a surface layer for protective-decorative coatings.

Copper plating is primarily used as the bottom layer in multi-layer plating of steel parts, and it is also commonly used as the base layer in tin plating, gold plating, and silver plating. Its main function is to enhance the bonding strength between the base metal and the surface or intermediate coating, facilitating the deposition of the surface coating. A non-porous copper plating layer can improve the corrosion resistance of the surface plating layer. For instance, the thick copper and thin nickel plating process in protective-decorative multilayer plating can help save precious nickel metal.

The properties and uses of nickel plating:

Nickel metal exhibits strong passivation ability, quickly forming a thin passivation film on the part’s surface that resists atmospheric corrosion and certain acids, giving nickel coatings excellent stability in the air. In a simple nickel salt electrolyte, a very fine crystalline coating can be achieved with outstanding polishing characteristics. Polished nickel coatings maintain a mirror-like luster for an extended period in atmospheric conditions and also offer high hardness and wear resistance.

Based on the characteristics of nickel plating, it is commonly employed as the bottom layer, middle layer, and surface layer in protective-decorative plating applications such as nickel-chromium plating, nickel-copper-nickel-chromium plating, copper-nickel-chromium plating, and copper-nickel plating.

Due to the high porosity of nickel plating, it only becomes non-porous when the plating layer thickness exceeds 25μm. Therefore, nickel plating layers are typically not utilized as protective plating layers.

The production of nickel plating is substantial, with about 10% of the world’s total nickel production being consumed by nickel plating processes.