Rapid Prototyping Assembly Services for Accelerated Product Development

Shorten Lead Times with Rapid Prototyping

Are you eager to bring your new product idea to life but concerned about long manufacturing lead times? Rapid prototyping assembly offers a solution to expedite the process. Learn how these services can help you launch your innovative design faster while maintaining top-notch quality.

Early Design Validation is Key

Validating your design through prototyping is a critical step in product development. Traditionally, this phase could take weeks due to lengthy PCB fabrication times. However, with rapid PCB assembly services, like those offered by WellCircuits LIMITED, prototype PCBs can now be assembled in as little as 3 business days. This rapid turnaround time allows engineers to iterate on designs quickly, making multiple revisions in a fraction of the usual time.

Receive Faster Feedback and Minimize Risk

Rapid prototyping enables quicker design validation, providing essential feedback earlier in the process. By identifying and addressing defects before full-scale production, you can significantly reduce the risk of costly errors down the line. This not only saves time but also ensures the final product meets the highest quality standards.

Accelerated Development Process

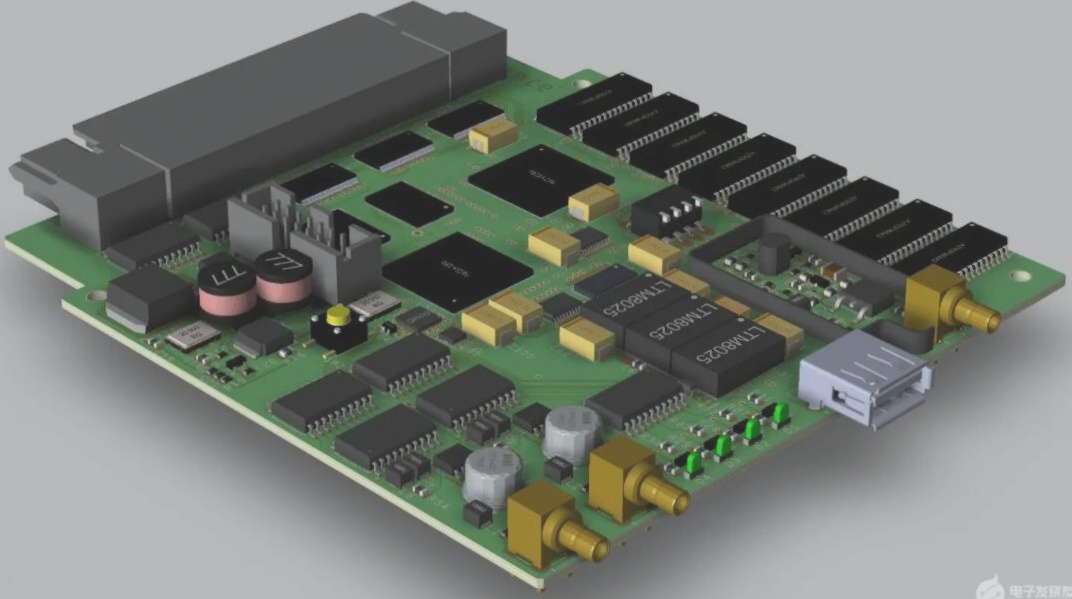

Once your initial PCB design is verified, incorporating additional components allows for the assembly of functional prototypes for comprehensive testing. Contract manufacturers specializing in rapid prototyping can deliver system-level prototypes within 1-2 weeks, facilitating smoother navigation through certification requirements. Functional prototypes bring products closer to market while meeting compliance standards.

Customized Solutions for Unique Challenges

While quick-turn services typically offer fixed turnaround times, certain projects may require accelerated schedules. Industry leaders like WellCircuits LIMITED understand the need for flexibility and provide guidance on the fastest development path based on specific requirements. Their expertise covers low to high quantities, ensuring timely deliveries even under tight deadlines.

Streamlined Development Process

As development progresses, fully assembled engineering samples become essential for testing before tooling. Contract manufacturers streamline this process with integrated supply chain management, delivering assembled prototypes within 10 working days. Early reliability testing identifies design weaknesses quickly, optimizing designs ahead of formal production.

Drive Innovation with Quick-Turn Services

Efficient quick-turn services compress product development cycles, allowing engineers to iterate designs faster and improve quality early in the process. This accelerated timeline enables innovative technologies to reach the market swiftly, giving companies a competitive edge.

The Benefits of Quick-Turn Prototype Services in PCB Development

- Accelerated Time-to-Market: Prototypes allow for faster iteration, risk mitigation, and optimization before scaling up for full production.

- Seamless Transition to Manufacturing: Retaining the same manufacturer from prototyping to production ensures lessons learned are integrated for consistent quality.

- Competitive Advantage: Companies can reduce development time, minimize risks, and bring innovative products to market faster.

Industry Expertise in Rapid Prototyping Assembly

Industry pioneers in rapid prototyping assembly services offer exceptional value with extensive experience serving high-technology sectors globally. Customers benefit from optimized assembly technologies, seamless supply chain integrations, and global manufacturing partnerships.

Collaborative Prototyping Specialists

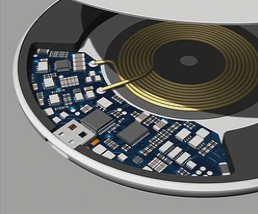

Leading prototyping specialists promote open collaboration to streamline product development cycles. They offer co-innovation labs, electronic/mechanical/thermal profiling, simulation, DFM analysis, and quick-turn PCB fabrication for complete solutions.

Custom Rapid Prototyping Services for Growth

Forward-thinking OEMs and startups leverage custom rapid prototyping services for exponential growth opportunities. These services empower ambitious projects with military-grade quality control, rapid timelines, and the ability to handle complex multi-board assembly architectures.

Revolutionizing Product Development with Rapid Prototyping Assembly

Rapid prototyping assembly services compress development cycles through faster design validation, iterations, and certifications. Strategic partnerships with global leaders ensure superior quality, minimize risks, accelerate time-to-market, and fuel continuous innovation.

Rapid Prototyping Assembly Services: Revolutionizing Product Development

Rapid prototyping assembly services have revolutionized the product development process, bringing about faster innovation, improved quality, and greater flexibility. By leveraging strategic global partnerships, ongoing technological advancements, and collaborative approaches, these services enable businesses to streamline their product development efforts, mitigate risks, and expedite time-to-market.

Enhanced Custom Solutions

Custom solutions, such as non-recurring engineering and multi-board assembly architectures, further elevate the capabilities of rapid prototyping services. These tailored solutions empower companies to introduce complex products to the market at unprecedented speeds, giving them a competitive edge in today’s rapidly evolving technological landscape.

Accelerating Commercial Success

Ultimately, rapid prototyping empowers companies to transform ambitious ideas into commercial success quickly. By offering significant competitive advantages, rapid prototyping services play a crucial role in helping businesses thrive in the fast-paced world of technology.