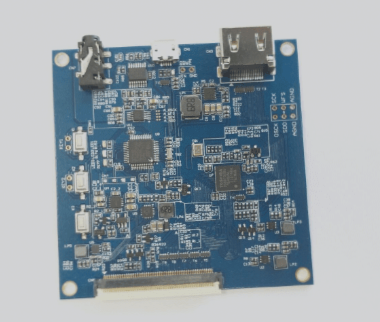

Rigid PCB Prototypes: Essential for Testing and Validation

A rigid PCB prototype serves as a crucial sample of a printed circuit board (PCB) created before the final product’s manufacturing stage. Its primary function lies in allowing designers to test and validate the functionality of their design before mass production. By utilizing methods like breadboarding, solderless breadboarding, or virtual prototyping through PCB design software, designers can ensure the efficiency of their PCB designs. This early testing phase helps in detecting and rectifying any design flaws, ultimately saving both time and money in the production process.

PCB Manufacturing Process: From Design to Assembly

- Design: The initial step involves designing the circuit board using specialized software to create a schematic layout of components and traces.

- Fabrication: The PCB design is then transferred to a copper-clad board, followed by chemical etching to remove excess copper.

- Drilling: Holes for components and vias are drilled into the board post-etching.

- Plating: A thin layer of metal, usually copper, is plated onto the board to create conductive traces.

- Soldermask: Application of a solder mask to protect copper areas and prevent solder bridges.

- Silkscreen: Components are labeled using a silk screen for identification.

- Assembly: Components are assembled onto the board either manually or using automated equipment.

The PCB manufacturing process demands expertise and precision to ensure the final product’s reliability and functionality.

PCB Testing: Ensuring Functionality and Reliability

PCB testing is a critical process that verifies the functionality and reliability of a printed circuit board before integration into a device or product. It involves visual inspection, electrical testing, and functional testing to meet required specifications and ensure correct performance. Testing is conducted at various stages, including after fabrication, component attachment, and final assembly, to detect faults early and enhance product quality.

Utilizing tools like visual inspection and automated optical inspection (AOI) ensures the quality and reliability of PCBs, meeting regulatory requirements and industry standards. Thorough testing is essential for product success and customer satisfaction.