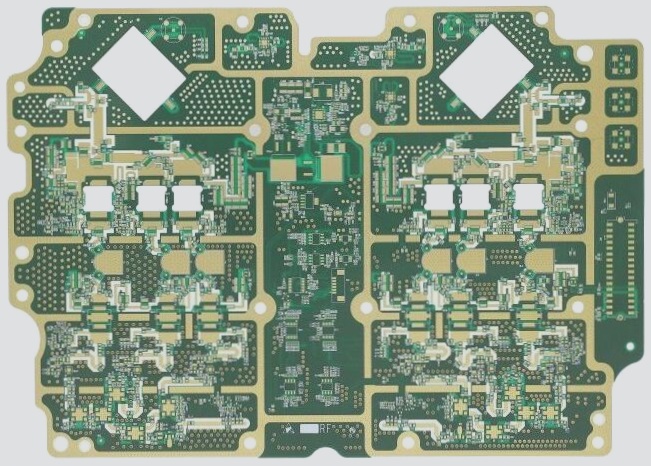

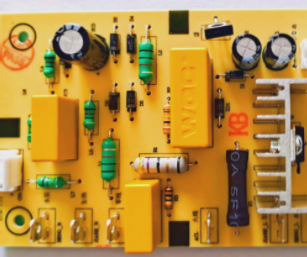

Circuit Board Soldering Advancements

- Circuit boards and PCB soldering technology have advanced significantly in recent years with the growth of the electronic industry.

- Reflow soldering technology is on the rise, including through-hole reflow soldering for traditional components.

- Reflow soldering offers simultaneous solder joint completion, reducing production costs.

- Temperature-sensitive components limit reflow soldering applications for both through-hole and SMD parts.

- Selective soldering is gaining attention as a follow-up to reflow soldering in many applications.

Quality Inspection Methods for PCB Soldering

- Inspection methods for PCB soldering quality include visual inspection, infrared detection, online testing, and more.

- Visual inspection is the most economical and widely used method, known for its cost-effectiveness and simplicity.

- Other methods like infrared detection and X-ray perspective offer higher inspection reliability but require specific equipment.

Defect Detection Methods

- Visual inspection tools range from magnifying glasses to camera-type screen display inspectors with adjustable magnification.

- Infrared detection method monitors heat release curves to detect voids within solder joints, suitable for automated soldering.

- X-ray perspective reveals solder thickness, shape, and quality distribution, especially effective for hidden solder joints.

Stay updated on the latest advancements in PCB soldering technology to ensure efficient and reliable electronic production processes.

Online PCB Testing Methods

The online testing method for PCBs involves the use of an online tester, which connects the test points on the circuit board to the tester through a signal connection component known as the “bed of needles.” This setup allows for the detection of open circuits, short circuits, faulty components, and verification of component functions such as resistance, capacitance values, and transistor polarity.

For evaluating the IC’s dummy solder pins, the IC floating pin test method can be employed. In situations where the circuit board has a high component density, making it difficult to establish the necessary test points, boundary scan technology can be utilized. This technology consolidates the test points through a designed test circuit to the edge connector of the soldering, facilitating the measurement of required points across various locations by the online tester.

Electrical Signal Testing for PCB Soldering

The online test method serves as an electrical signal testing technique to evaluate the soldering status of PCBs. This inspection closely resembles real-world conditions, where circuit board welds tested online can be integrated into machines. However, it does not offer definitive quality results for soldering, and the reliability of solder joints cannot be intuitively verified.

Should you require any further modifications or additional details, please do not hesitate to reach out!