Formation and Response of Voids

When heating the solder joint, organic materials in the solder paste can become trapped inside, forming gas voids or holes within the joint. This issue is exacerbated when the solder paste absorbs water. These voids are spherical in shape and are known as back-welding voids. It is crucial to differentiate them from voids found in wave soldering.

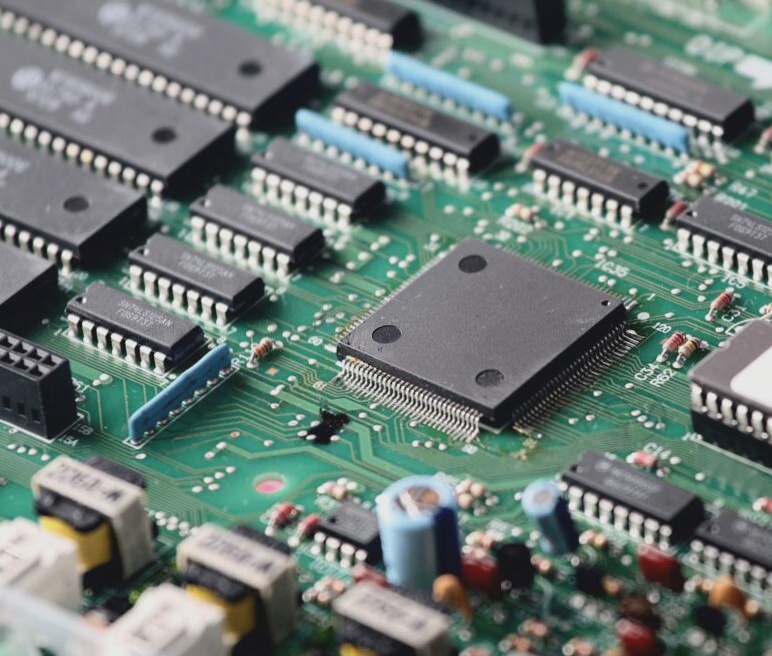

Holes in BGA Pad

The largest and most numerous voids in lead-free solder paste joints are often found in BGA or CSP ball pin solder joints. These voids can be caused by various factors, including the formation of holes in the solder paste during the ball planting process. The prevalence of HDI interconnection technology has introduced new methods that reduce the need for traditional PTH connections, improving signal integrity and reducing noise. Advances in copper electroplating technology have also helped address void issues in solder joints, particularly in BGA areas.

Voids from Surface Treatment

In some cases, voids in solder joints can also be attributed to surface treatment processes. It is important to consider how different surface treatments may impact the formation of voids and take steps to mitigate these issues during PCB manufacturing.

PCBA Surface Treatment Films and Solutions

- High organic content films like I-Ag and OSP can crack into small holes under strong heat, known as “interface microholes”.

- To prevent tarnishing and silver metal migration, a thin organic protective film is applied on the silver-dipped layer.

- Improving surface treatment formula and process can help avoid silver immersion issues.

- New generation OSP films offer improved compactness, protecting copper from oxidation even with a 0.3μm thickness.

- Proper OSP film removal in wave or reflow welding is crucial to prevent cracking and gas formation.

- Using nitrogen in the reflow furnace can significantly improve OSP film performance.

Tin Powder and Flux Oxidation Issues

- Extended heat absorption during reflow can lead to oxidation of tin powder and flux, causing holes in solder joints.

- Choosing flux with good oxidation resistance or using a nitrogen environment in back-welding can help mitigate oxidation problems.

Solder Pad Rejection and Voids on PCB Boards

- Various surface treatments for PCB copper pads can lead to solder rejection and void formation.

- Uneven tin surfaces on BGA ball pads can result in large holes during solder paste reflow.

- Issues with PCB pad treatment often occur in wide-stage BGA ball pins rather than narrow solder joints like QFP.

Preventing Large Holes in PCBs Caused by Organic Matter Failure

When organic matter fails to escape from PCBs, it can lead to the formation of holes. These holes may start small but can expand significantly if the PCB is exposed to moisture after printing the paste. The enlarged holes can even cause adjacent ball feet to be blown and squeezed into a short circuit. This issue is common in both lead and lead-free PCBs.

To prevent this problem, it is crucial to keep the solder paste in a low-temperature and dry environment. If the PCB is exposed to high humidity (90% RH) for just 20 minutes, it can absorb enough water to create large holes. This can result in the splattering of molten tin, leading to additional tin spots on the PCB.

Holes from BGA Upstream Packaging

When it comes to Ball Grid Array (BGA) packaging, solder paste is used for positioning and soldering the ball feet. During the ball planting process in the reflow furnace, the same solder paste welding principle applies, which can also result in holes.

During quality checks, it is essential to inspect the BGA for holes using X-ray fluoroscopy with the abdomen facing up. This step helps to avoid potential issues later on, especially when dealing with the challenges of “easy to break the head and difficult to break the foot” on the FR4 PCB.