Key Considerations for Choosing a Reliable Rigid-Flex PCB Manufacturer

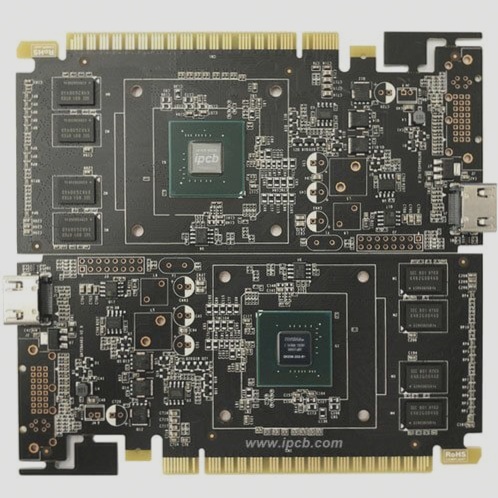

PCB Manufacturing Process

- PCB manufacturing involves fabrication and assembly.

- Rigid-flex PCBs may not have large volume orders like rigid PCBs.

- Collaborating with a fabricator offering turnkey assembly services can expedite delivery and reduce costs.

- Confirm if the fabricator provides assembly services when selecting one.

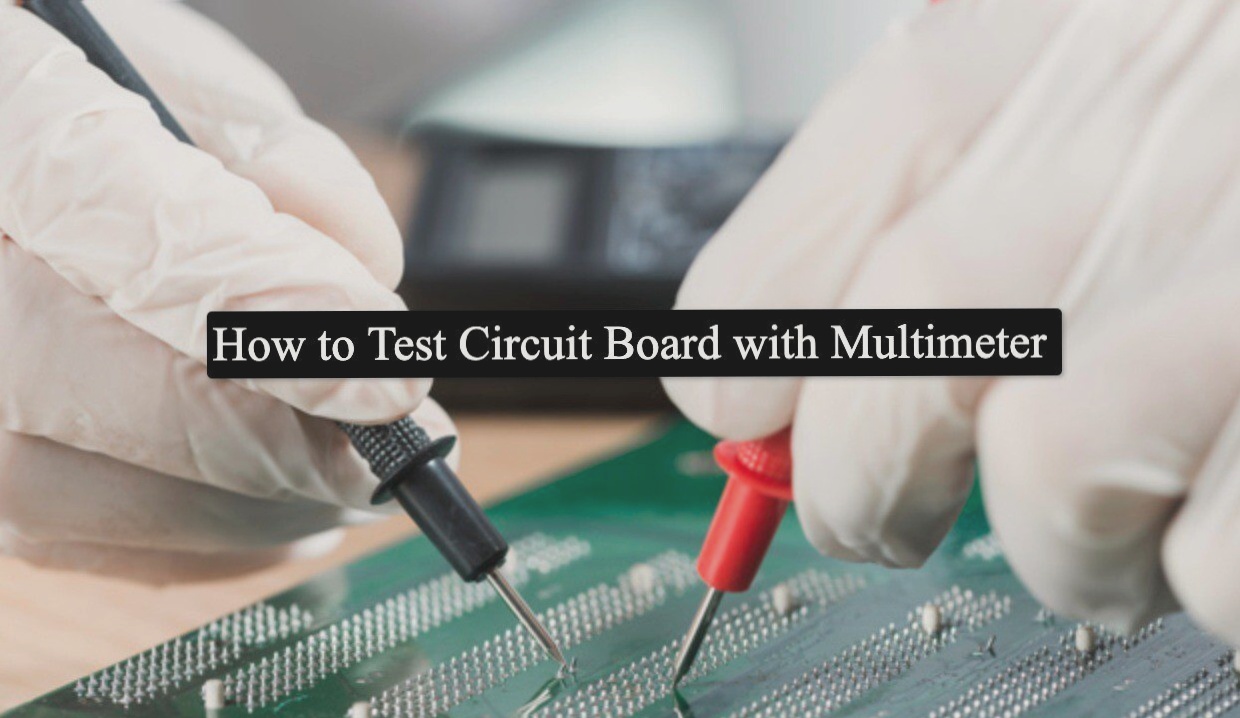

Assessing Manufacturer Capability

- Look for detailed descriptions of key parameters like final thickness, impedance control, and copper thickness.

- Verify the manufacturer’s capacity for volume production to avoid potential disasters.

Effective Communication

- Communication is vital, especially when dealing with international suppliers.

- Regular updates and revisions in PCB projects require clear communication channels.

Elements for Inquiry

- Initiate inquiries with potential rigid-flex PCB suppliers based on the provided elements.

Latest Innovations in Rigid-Flex PCBs

- Featuring 0.1mm buried microvias and a super-thin 0.8mm final thickness for optimal interconnectivity and bending performance.

- 6-layer configuration and 2-tier HDI design for exceptional reliability in demanding environments.

- 8-layer count and HDI design for higher circuitry density.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย