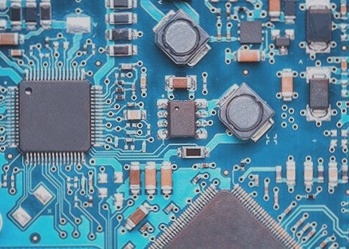

Benefits of Test Points in PCB Design

Adding test points to circuit board design plays a crucial role in ensuring the quality and functionality of the final product. Test points are essential for conducting thorough assessments and identifying potential issues. Here are some key reasons why test points are important:

- Assessment of Soldering Integrity: Test points are used during the In-Circuit Test (ICT) process to evaluate soldering integrity and overall performance compliance after PCB assembly.

- Identification of Circuit Continuity: Test points serve as contact points for testing circuit continuity, helping to detect open or short circuits effectively.

- Protection of SMT Components: By integrating test points along network lines, the risk of damaging delicate Surface Mount Technology (SMT) components during testing with a needle bed is minimized.

- Enhanced Testing Accuracy: Including test points in the design ensures accurate testing without compromising component integrity, leading to reliable performance assessment.

- Adaptation to Modern Challenges: While traditional guidelines suggested adding test points to 90% of networks, modern challenges such as needle size limitations and high-density boards require strategic placement of test points for effective testing.

- Alternative Testing Methods: In cases where space limitations hinder the incorporation of numerous test points, alternative testing methods like JTAG, X-Ray, and AOI provide viable options to supplement ICT testing.

- Comprehensive Testing Strategies: The PCB design service process evolves to incorporate comprehensive testing strategies, ensuring the quality and reliability of the final PCB product.