1. The reason why customers choose processing plants to handle SMT patches is that the quantity is large and the price will be relatively cheap. These are all factors that customers consider when making choices. I just want to find an SMT chip processing factory, but in many cases, manufacturers are unwilling to accept this order because small batch orders are not cost-effective unless the order volume is large. In the case of small batches, the so-called loss is significant and also a waste of time. Because the production efficiency is high when processing SMT patches, and there is no waste of time on early preparation work after production.

2. Is the cost of converting small batches of SMT patches too high?

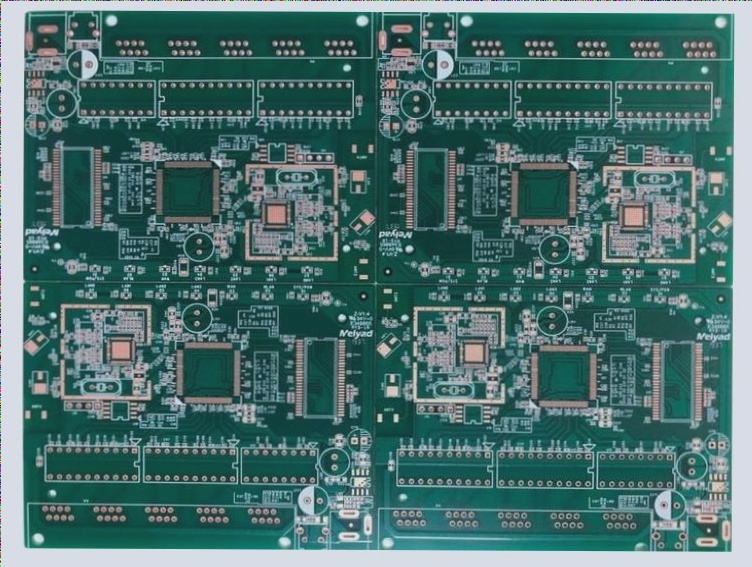

3. The cost of converting small batch SMT patches is indeed too high. The investment of manpower and material resources cannot make up for the cost. For example, if only 100 pieces are produced, the depreciation cost of expensive equipment is indeed not worth it. Unless the customer has a long-term partnership with these factories, the cost issue is obvious. Because before SMT chip processing, whether it is large-scale or small-scale SMT chip processing, the preliminary work is the same, such as programming of SMT chip processing machines, PCB positioning, and initial part confirmation.

2. Some SMT patch processing plants are reluctant to take small orders due to differing processing costs. Certain manufacturers prefer to cater to their own users, while others specialize in serving large customers because they offer higher volumes and more stable orders. Generally, the profit from a single product is not very high. By securing a number of large customers, a processing plant can avoid dealing with scattered orders and their associated factors. Is the high cost of SMT patch processing due to small batch sizes?

3. Anyone familiar with SMT patch processing knows that the cost is generally calculated based on the number of components. One patch (e.g., resistor 0603, 0805, capacitor, diode) is counted as one point, one transistor as 1.5 points, and the four pins of an IC are counted as one point. All patch points on the PCB board are totaled, with the processing fee calculated as points multiplied by the unit price per point. This fee includes costs for red glue, solder paste, washing water, and other auxiliary materials. If the number of SMT patch processing points is very low, the factory’s cost calculations might show a minimum threshold, such as 500 points. Large-volume processing is more appealing to factories because small batches often incur high labor and equipment wear costs, which can lead to inefficient use of time. This is why small batch SMT patch processing and prototyping often incur additional engineering fees.