Evolution of Printed Circuit Boards (PCBs)

- In 1936, Paul Eisler introduced printed circuit boards (PCBs) in radios, marking the beginning of a revolutionary technology.

- By 1943, the US military widely adopted PCBs for radios, showcasing their effectiveness and reliability.

- In 1948, the United States officially sanctioned the commercial use of printed circuit boards, paving the way for their widespread application.

- During the mid-1950s, PCBs started gaining popularity, replacing direct wire interconnections in electronic devices.

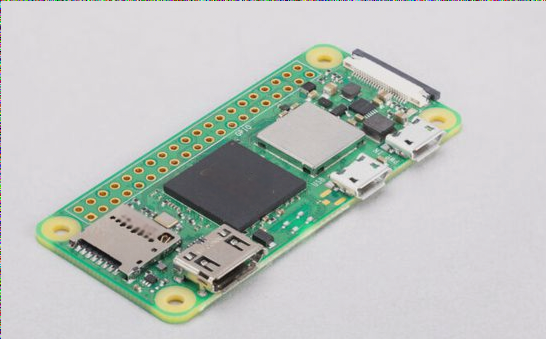

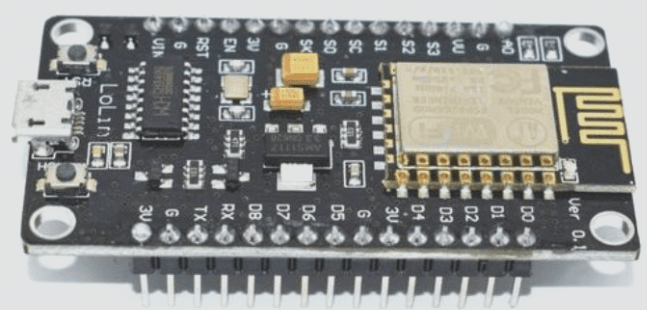

- Today, printed circuit boards dominate the electronics industry, with wires mainly reserved for laboratory testing purposes.

- The use of multilayer boards with multiple layers has enabled increased wiring density and improved functionality.

With the advancement of technology, the manufacturing process of PCBs has evolved:

- Copper clad laminate, a crucial substrate material for PCBs, facilitates electrical connections and insulation among components.

- Technological advancements in the early 20th century laid the foundation for copper clad laminates, the most prevalent PCB substrate material.

- PCB manufacturing involves lamination, where inner layers, prepregs, and copper foils are pressed together to create multilayer boards.

- Drilling processes for multilayer PCBs are carried out in stages, including copper immersion and non-plated holes for various features.

- PCB manufacturing utilizes a photosensitive film to create circuit patterns on the board’s surface through exposure to ultraviolet light.

- Solder mask, like green oil, safeguards conductive areas on PCBs, preventing short circuits and enhancing longevity.

- Computer motherboards, typically four or six-layer PCBs, vary in design to optimize performance and reduce electromagnetic interference.