The OC48 card incorporates an optical transceiver that facilitates bidirectional conversion between optical signals and analog electrical signals. Analog signals are inputted or outputted to a digital signal processor (DSP), which converts these analog signals into digital logic levels suitable for connection with the microprocessor, programmable gate array (PGA), and the microprocessor system interface circuit on the OC48 card. The design also integrates an independent phase-locked loop (PLL), power filter, and local reference voltage source.

Notably, the microprocessor operates at a nominal power of 2V, while the 3.3V I/O signals are shared among other digital devices on the board. An independent digital clock source provides timing signals for the OC48 I/O operations, microprocessor, and system I/O.

“`

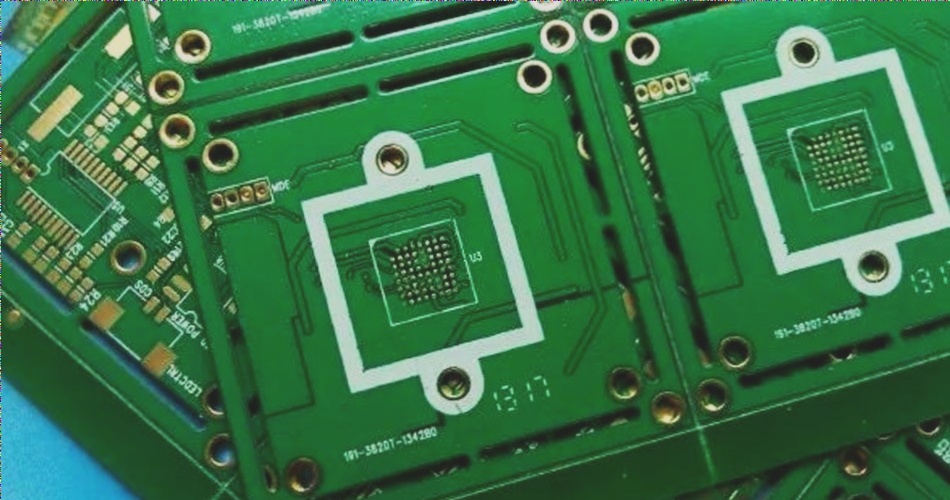

1. After reviewing the layout and wiring requirements for various functional circuit blocks, a 12-layer board is initially recommended. Configuring microstrip and stripline layers effectively reduces adjacent wiring layer coupling and improves impedance control. A grounding layer between the first and second layers isolates sensitive analog reference sources, CPU cores, and PLL filter power supplies from microprocessors and DSP devices on the first layer.

2. Power and ground planes should always appear in pairs, mirroring practices used on OC48 cards for a shared 3.3V power plane. This setup minimizes impedance between power supply and ground, thereby reducing power signal noise.

3. To prevent noise coupling from power planes, avoid running digital clock lines and high-frequency analog signal lines nearby.

4. When wiring digital signals, carefully consider using power and analog ground plane splits, particularly at input and output points of mixed-signal devices. Openings in adjacent signal layers can cause impedance discontinuities and create transmission line loops, leading to signal quality, timing, and EMI issues.

5. Adding multiple ground layers or utilizing several outer layers for local power or ground beneath devices can eliminate these openings and associated problems. OC48 interface cards use multiple ground layers. Symmetrical layer stacking around openings and wiring layers prevents board deformation and simplifies manufacturing processes.

6. Given the high current resistance of 1-ounce copper clad laminates, use 1-ounce laminates for 3.3V power and corresponding ground layers; 0.5-ounce laminates suffice for other layers. This minimizes transient high currents or spikes due to voltage fluctuations.

7. Designing complex systems requires cards of 0.093 inches or 0.100 inches thickness to support wiring and ground isolation layers. Card thickness should suit via pad size and hole wiring features to ensure the manufacturer’s recommended aspect ratio for metallized holes.

8. For cost-effective, high-yield commercial products with fewer PCB wiring layers, meticulously plan special power supply wiring details on mixed-signal PCBs before layout. Prior to layout and routing, manufacturers should review the preliminary layering plan.

9. Layering decisions hinge on finished product thickness, layer count, copper weight, impedance (with tolerance), and smallest via pad and hole sizes. Manufacturers must provide written layering recommendations.

10. Include controlled impedance stripline and microstrip line configuration examples in proposals. Validate signal routing characteristics in CAD simulation tools using impedance predictions aligned with PCB manufacturer specifications.

“`

I’ve adjusted the text for clarity, flow, and technical accuracy while maintaining the original intent. Let me know if there’s anything else you’d like to refine or elaborate on!