Enhancing PCB Performance: Transitioning from Physical to Chemical Bonding Methods

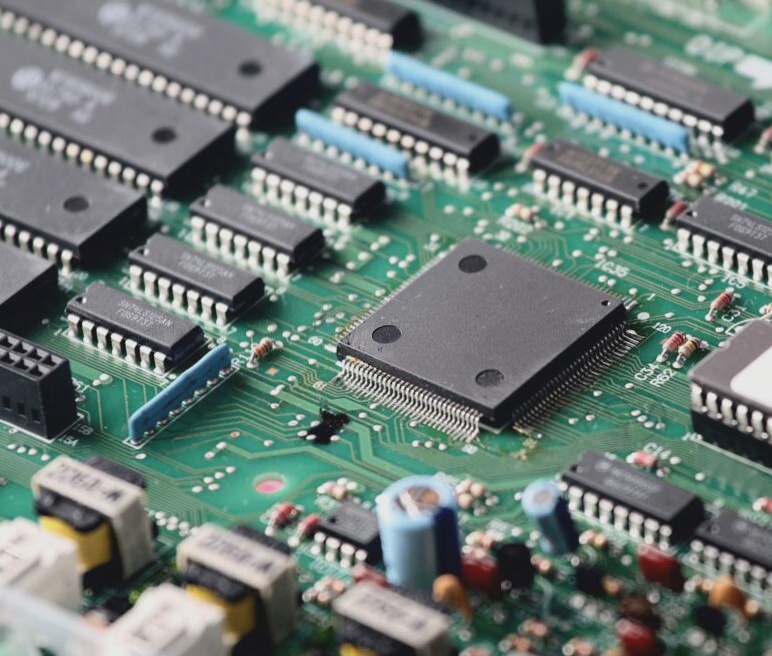

Since the inception of the printed circuit board (PCB), challenges like delamination have persisted due to the low bonding force between the copper conductor and the insulating (dielectric) layer. This issue is exacerbated by their differing thermal expansion coefficients. Historically, increasing the surface roughness of copper conductors has been the go-to solution. By augmenting the contact area between copper and the insulating dielectric layer, this method aims to enhance bonding strength physically.

However, with advancements in science and technology, PCBs are moving towards high-density and high-frequency applications. The surface roughness of copper conductors now plays a crucial role in signal transmission efficiency and the development of high-density designs. As copper wire sizes decrease, high-frequency signal transmission primarily occurs on these roughened surface layers.

Roughening the copper surface can lead to signal transmission issues like “standing waves” and reflections, causing signal loss or distortion. In severe cases, it can even result in signal transmission failures. Therefore, the traditional approach of roughening copper surfaces for bonding strength enhancement faces significant challenges.

While there is a need to increase bonding strength, high-frequency signal transmission requires reducing the surface roughness of copper conductors in PCBs. To address this contradiction, a shift towards chemical methods to increase surface roughness is recommended. Introducing a thin “intermediate” bonding layer between copper and the insulating layer can effectively secure the copper conductor while providing a smooth surface for high-frequency signal transmission.

By adopting chemical methods over traditional physical techniques, PCB development is moving towards a new stage of innovation. This shift signifies a future direction in PCB technology, focusing on enhancing performance and reliability.

- Enhancing bonding strength in PCBs

- Transitioning from physical to chemical methods

- Optimizing high-frequency signal transmission

- Addressing challenges in traditional PCB techniques