The Benefits and Challenges of Flexible Circuit Boards

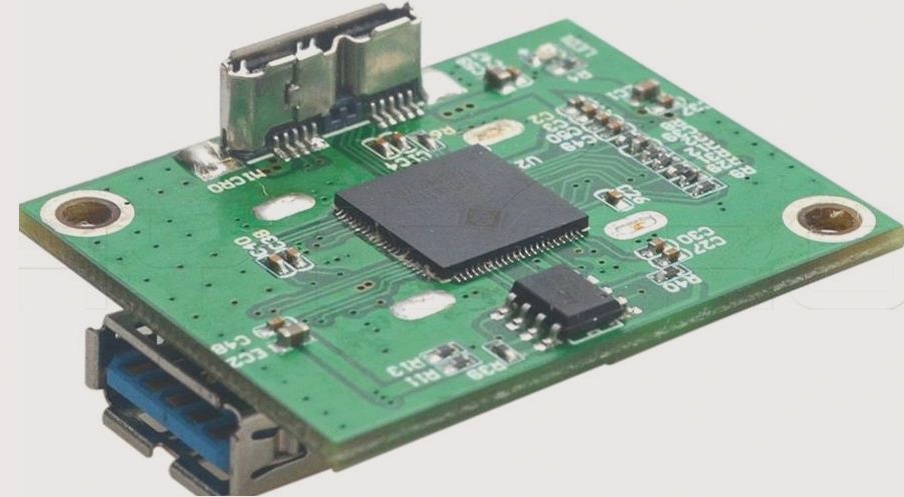

- Flexible circuit boards, also known as FPCs, are lightweight and compact boards made from polyimide or polyester film.

- They offer excellent insulation, sealing properties, radiation resistance, and high-temperature tolerance.

- Advancements in process design now allow for high-density SMT to be applied to FPCs.

- However, due to their flexible nature, the reliability of chip ICs and components on FPCs may be lower than traditional PCBs.

- To enhance reliability, many manufacturers use component dispensing and reinforcement techniques.

Enhancing Reliability with Dispensing and Reinforcement

Many FPC manufacturers are adopting dispensing and reinforcement methods to improve board reliability. Choosing the right dispenser and adhesive is crucial for this process.

Choosing the Right Dispenser

International brands like Musashi, EFD, and Asymtek offer various dispenser types, including controller-based, desktop, semi-automatic, and fully automatic models. Domestic brands like AXXON Axis and Dongguan Anda also provide options. Factors like production capacity and order requirements should influence the choice of dispenser.

Selecting the Proper Adhesive

Single-component epoxy resin glue is commonly used for FPC reinforcement. This adhesive requires a curing agent and heat to initiate the curing process. Once cured, epoxy resin glue offers high bonding strength and resistance to high temperatures, impact, and vibration.

Addressing Common Issues

Bubbles and air pockets are common problems during FPC IC reinforcement dispensing. Methods like autonomous defoaming and passive defoaming can help eliminate bubbles. Proper cleaning of bonding surfaces and careful adhesive application are essential to prevent these issues.

If you have any questions about PCBs, feel free to contact us at info@wellcircuits.com.