1. This paper introduces an ultimate PC-based serial port test system for PCB board remote fault diagnosis.

2. It features an advanced design, a concise structure, powerful functions, high cost-effectiveness, and easy portability.

3. The use shows that the proposed design scheme is feasible.

1. System Overall Structure Design

The PC generates control commands for each step of the detection process based on the detection process file. These commands are sent to the single-chip testing system via the RS-232C serial interface. Upon completion of the detection, the system receives and processes the measurement results from the single-chip testing system. It then formulates fault diagnosis conclusions and displays the PCB board’s detection results on the system’s soft panel display window (operation interface). The system manages the entire detection and diagnosis process of the PCB board.

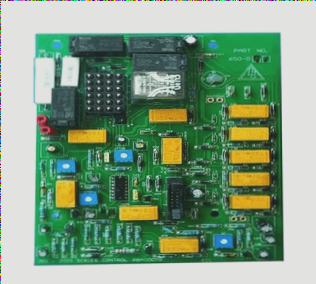

2. Networking Capability

The system can connect to a network through network interface equipment, enabling it to function as an intelligent remote fault diagnosis system with network capabilities. It can further evolve into a remote measurement and control system or a remote management system, facilitating wired/wireless channel remote data communication to achieve digitalization of the measurement and control system. This networking capability breaks geographical and quantitative deployment boundaries to some extent, allowing for shared hardware and software resources, tasks, and loads across the entire network system.

3. Single-Chip Measurement and Control Instrument System

The single-chip measurement and control instrument system primarily consists of an AT89C52 single-chip microcomputer, a serial communication module, a frequency measurement and counting module, a voltage measurement module, and a program-controlled switch matrix for channel control. This system achieves serial communication, frequency and voltage measurements, counting, and control signal generation.

4. Signal Processing and Excitation

Signal sampling and reception involve level conversion, signal conditioning, and sampling of the measured signal under the control of the single-chip microcomputer. These processed signals serve as inputs for the measurement circuit of the single-chip measurement and control instrument system. The excitation signal source, controlled by the single-chip microcomputer, provides necessary working power or excitation signals for the external object connected to the socket.

5. Programmable Switch Matrix and External Socket

The programmable switch matrix serves as the input/output channel for excitation signals and response signals. It enables program-controlled switching of the excitation signals for each pin of the external socket, supplying required power and excitation signals to each pin and receiving frequency or voltage output signals from these pins. The 24-pin external socket acts as the interface between the measured object and the single-chip measurement and control instrument system, accommodating the 24-pin general PCB board to be tested.

6. Manual Test Probe

A manual test probe performs signal level sampling at specific observation points on the PCB board. It can also input excitation signals as needed for manual fault detection.

7. Serial Communication Module

The serial communication module utilizes a zero modem connection for short-range communication with a transmission distance of less than 15m. It provides input/output channels for transmitting PC control commands and measurement data from the single-chip test system.

8. Main Control Software

The main control software comprises PC measurement and control software and single-chip test software. The PC measurement and control software, developed in the Windows environment using Microsoft Visual Basic 6.0, coordinates system operations. Meanwhile, the single-chip test software, coded in MCS-51 assembly language, manages the operations of the single-chip microcomputer.

9. System Functions

Key functionalities include system self-checks (power-on and key-press self-checks), automatic diagnosis, and manual diagnosis. User feedback indicates that the system offers stable performance, reliable operation, a user-friendly interface, simple maintenance, and portability. These attributes contribute to its clear application advantages and promising development prospects, as affirmed by technical evaluations from relevant organizations.

10. Conclusion

The PCB board remote fault diagnosis system adopts a serial port test system design based on a PC, featuring advanced design, a concise structure, powerful functionality, and high cost-effectiveness. Its success provides valuable insights for similar applications in various fields.

—

This revision aims to clarify technical details, improve readability, and maintain consistency in describing the system’s capabilities and components.

2. It features an advanced design, a concise structure, powerful functions, high cost-effectiveness, and easy portability.

3. The use shows that the proposed design scheme is feasible.

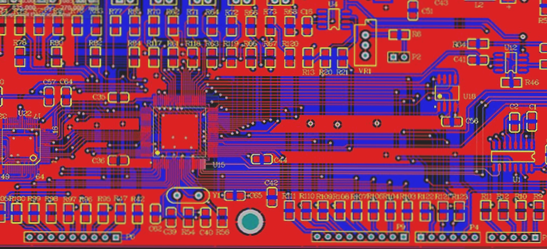

1. System Overall Structure Design

The PC generates control commands for each step of the detection process based on the detection process file. These commands are sent to the single-chip testing system via the RS-232C serial interface. Upon completion of the detection, the system receives and processes the measurement results from the single-chip testing system. It then formulates fault diagnosis conclusions and displays the PCB board’s detection results on the system’s soft panel display window (operation interface). The system manages the entire detection and diagnosis process of the PCB board.

2. Networking Capability

The system can connect to a network through network interface equipment, enabling it to function as an intelligent remote fault diagnosis system with network capabilities. It can further evolve into a remote measurement and control system or a remote management system, facilitating wired/wireless channel remote data communication to achieve digitalization of the measurement and control system. This networking capability breaks geographical and quantitative deployment boundaries to some extent, allowing for shared hardware and software resources, tasks, and loads across the entire network system.

3. Single-Chip Measurement and Control Instrument System

The single-chip measurement and control instrument system primarily consists of an AT89C52 single-chip microcomputer, a serial communication module, a frequency measurement and counting module, a voltage measurement module, and a program-controlled switch matrix for channel control. This system achieves serial communication, frequency and voltage measurements, counting, and control signal generation.

4. Signal Processing and Excitation

Signal sampling and reception involve level conversion, signal conditioning, and sampling of the measured signal under the control of the single-chip microcomputer. These processed signals serve as inputs for the measurement circuit of the single-chip measurement and control instrument system. The excitation signal source, controlled by the single-chip microcomputer, provides necessary working power or excitation signals for the external object connected to the socket.

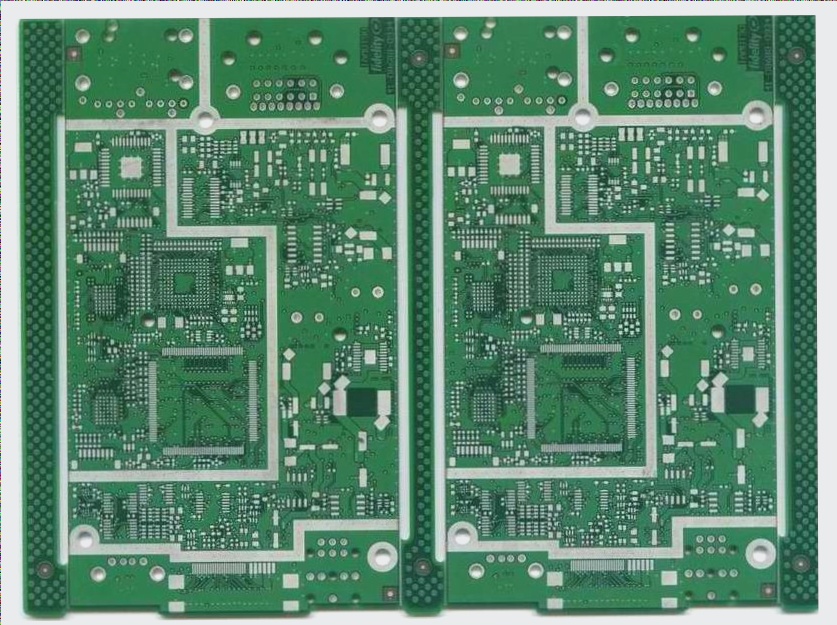

5. Programmable Switch Matrix and External Socket

The programmable switch matrix serves as the input/output channel for excitation signals and response signals. It enables program-controlled switching of the excitation signals for each pin of the external socket, supplying required power and excitation signals to each pin and receiving frequency or voltage output signals from these pins. The 24-pin external socket acts as the interface between the measured object and the single-chip measurement and control instrument system, accommodating the 24-pin general PCB board to be tested.

6. Manual Test Probe

A manual test probe performs signal level sampling at specific observation points on the PCB board. It can also input excitation signals as needed for manual fault detection.

7. Serial Communication Module

The serial communication module utilizes a zero modem connection for short-range communication with a transmission distance of less than 15m. It provides input/output channels for transmitting PC control commands and measurement data from the single-chip test system.

8. Main Control Software

The main control software comprises PC measurement and control software and single-chip test software. The PC measurement and control software, developed in the Windows environment using Microsoft Visual Basic 6.0, coordinates system operations. Meanwhile, the single-chip test software, coded in MCS-51 assembly language, manages the operations of the single-chip microcomputer.

9. System Functions

Key functionalities include system self-checks (power-on and key-press self-checks), automatic diagnosis, and manual diagnosis. User feedback indicates that the system offers stable performance, reliable operation, a user-friendly interface, simple maintenance, and portability. These attributes contribute to its clear application advantages and promising development prospects, as affirmed by technical evaluations from relevant organizations.

10. Conclusion

The PCB board remote fault diagnosis system adopts a serial port test system design based on a PC, featuring advanced design, a concise structure, powerful functionality, and high cost-effectiveness. Its success provides valuable insights for similar applications in various fields.

—

This revision aims to clarify technical details, improve readability, and maintain consistency in describing the system’s capabilities and components.