1. PCB Size

[Background Description]

The dimensions of the PCB are constrained by the capabilities of the electronic manufacturing equipment. Therefore, it’s essential to consider the suitable PCB size when designing the product system.

(1) The largest PCB size that can be accommodated by SMT equipment is dictated by standard PCB material dimensions, with most being 20″*24″, equivalent to 508mm*610mm (rail width).

(2) The recommended dimensions align with the capabilities of SMT production line equipment, enhancing the production efficiency of each machine and minimizing bottlenecks.

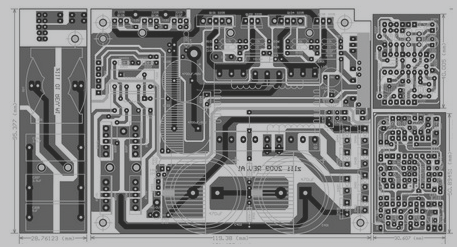

(3) For smaller PCBs, they should be designed in an imposition layout to boost the overall production efficiency of the line.

【Design Requirements】

(1) Generally, the maximum PCB dimensions should be restricted to a range of 460mm*610mm.

(2) The advised size range is (200~250)mm*(250~350)mm, with an aspect ratio of <2.

(3) For PCBs sized <125mm*125mm, an appropriate size configuration should be established.

2. PCB Shape

[Background Description]

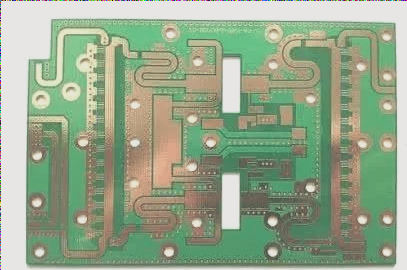

SMT production equipment utilizes guide rails for transporting PCBs, which limits their capability to handle irregularly shaped PCBs, particularly those with corner gaps.

[Design Requirements]

(1) The PCB shape should be a regular square with rounded corners.

(2) To ensure stable transmission, irregular PCB shapes should be standardized into a square format, with corner gaps filled to prevent jamming during the wave soldering process.

(3) For pure SMT boards, gaps are permissible but must not exceed one-third of the adjacent side’s length. Exceeding this requires filling during design.

(4) Besides chamfering the insertion side, the golden fingers should also feature a (1~1.5)*45° chamfer on both sides to facilitate insertion.

3. Transmission Side

[Background Description]

The conveying edge size is determined by the requirements of the equipment’s guide rail. Typically, printing machines, placement machines, and reflow soldering furnaces require a conveying edge of at least 3.5mm.

[Design Requirements]

(1) To minimize PCB deformation during soldering, the long side of non-imposed PCBs should generally align with the transmission direction; imposed PCBs should follow the same guideline.

(2) Typically, the two sides of the PCB aligned with the transmission direction serve as the transmission side, with a minimum width of 5.0mm. No components or solder joints should be present on either side of the transmission edge.

(3) There are no restrictions for the non-transmission side regarding SMT equipment, but it’s advisable to maintain a 2.5mm component exclusion zone.

4. Positioning Hole

[Background Description]

Accurate PCB positioning is crucial for processes like imposition, assembly, and testing, necessitating the inclusion of positioning holes.

[Design Requirements]

(1) Each PCB should feature at least two positioning holes: one circular and one elongated for guiding. Positioning apertures can be tailored to factory specifications, with recommended diameters of 2.4mm and 3.0mm. These holes should be non-metallized; for punched PCBs, use a hole plate to enhance rigidity. The length of the guide hole should generally be twice its diameter. Positioning holes must be more than 5.0mm from the transmission edge and spaced as far apart as possible, ideally located at opposite corners of the PCB.

(2) For mixed PCBs (PCBA with installed plug-ins), the positioning holes should align to allow shared tooling design for both sides, such as using the same screw bottom bracket for the plug-in tray.

5. Positioning Symbol

[Background Description]

Modern placement machines, printing machines, and optical inspection equipment (AOI) rely on optical positioning systems, necessitating the design of optical positioning symbols on the PCB.

[Design Requirements]

(1) Positioning symbols are categorized into global positioning symbols (Global Fiducial) for whole board alignment and local positioning symbols (Local Fiducial) for imposition sub-boards or fine-pitch components.

(2) Optical positioning symbols can be square, diamond-shaped, cross, or tic-tac-toe, with a height of 2.0mm. A Ø1.0mm round copper definition pattern is recommended, ensuring a non-soldering area 1mm larger than the symbol itself, free of any characters. Consistency in copper foil presence beneath each symbol on the inner layer is essential.

(3) On PCBs with SMD components, it’s advisable to position three optical symbols at the board corners for three-dimensional alignment (three points define a plane, aiding in solder paste thickness detection).

(4) For imposition, in addition to the three global optical symbols, it’s beneficial to include two or three for imposition at each unit board’s diagonal corners.

(5) Local optical symbols should be placed at diagonal corners for components like QFP with lead center distances ≤0.5mm and BGA with ≤0.8mm.

(6) If components are mounted on both sides, optical symbols must be placed on each side.

(7) If no positioning hole exists on the PCB, the optical symbol’s center should be more than 6.5mm from the transmission edge. If a positioning hole is present, the symbol should be positioned near the center of the PCB on the side of the hole.

[Background Description]

The dimensions of the PCB are constrained by the capabilities of the electronic manufacturing equipment. Therefore, it’s essential to consider the suitable PCB size when designing the product system.

(1) The largest PCB size that can be accommodated by SMT equipment is dictated by standard PCB material dimensions, with most being 20″*24″, equivalent to 508mm*610mm (rail width).

(2) The recommended dimensions align with the capabilities of SMT production line equipment, enhancing the production efficiency of each machine and minimizing bottlenecks.

(3) For smaller PCBs, they should be designed in an imposition layout to boost the overall production efficiency of the line.

【Design Requirements】

(1) Generally, the maximum PCB dimensions should be restricted to a range of 460mm*610mm.

(2) The advised size range is (200~250)mm*(250~350)mm, with an aspect ratio of <2.

(3) For PCBs sized <125mm*125mm, an appropriate size configuration should be established.

2. PCB Shape

[Background Description]

SMT production equipment utilizes guide rails for transporting PCBs, which limits their capability to handle irregularly shaped PCBs, particularly those with corner gaps.

[Design Requirements]

(1) The PCB shape should be a regular square with rounded corners.

(2) To ensure stable transmission, irregular PCB shapes should be standardized into a square format, with corner gaps filled to prevent jamming during the wave soldering process.

(3) For pure SMT boards, gaps are permissible but must not exceed one-third of the adjacent side’s length. Exceeding this requires filling during design.

(4) Besides chamfering the insertion side, the golden fingers should also feature a (1~1.5)*45° chamfer on both sides to facilitate insertion.

3. Transmission Side

[Background Description]

The conveying edge size is determined by the requirements of the equipment’s guide rail. Typically, printing machines, placement machines, and reflow soldering furnaces require a conveying edge of at least 3.5mm.

[Design Requirements]

(1) To minimize PCB deformation during soldering, the long side of non-imposed PCBs should generally align with the transmission direction; imposed PCBs should follow the same guideline.

(2) Typically, the two sides of the PCB aligned with the transmission direction serve as the transmission side, with a minimum width of 5.0mm. No components or solder joints should be present on either side of the transmission edge.

(3) There are no restrictions for the non-transmission side regarding SMT equipment, but it’s advisable to maintain a 2.5mm component exclusion zone.

4. Positioning Hole

[Background Description]

Accurate PCB positioning is crucial for processes like imposition, assembly, and testing, necessitating the inclusion of positioning holes.

[Design Requirements]

(1) Each PCB should feature at least two positioning holes: one circular and one elongated for guiding. Positioning apertures can be tailored to factory specifications, with recommended diameters of 2.4mm and 3.0mm. These holes should be non-metallized; for punched PCBs, use a hole plate to enhance rigidity. The length of the guide hole should generally be twice its diameter. Positioning holes must be more than 5.0mm from the transmission edge and spaced as far apart as possible, ideally located at opposite corners of the PCB.

(2) For mixed PCBs (PCBA with installed plug-ins), the positioning holes should align to allow shared tooling design for both sides, such as using the same screw bottom bracket for the plug-in tray.

5. Positioning Symbol

[Background Description]

Modern placement machines, printing machines, and optical inspection equipment (AOI) rely on optical positioning systems, necessitating the design of optical positioning symbols on the PCB.

[Design Requirements]

(1) Positioning symbols are categorized into global positioning symbols (Global Fiducial) for whole board alignment and local positioning symbols (Local Fiducial) for imposition sub-boards or fine-pitch components.

(2) Optical positioning symbols can be square, diamond-shaped, cross, or tic-tac-toe, with a height of 2.0mm. A Ø1.0mm round copper definition pattern is recommended, ensuring a non-soldering area 1mm larger than the symbol itself, free of any characters. Consistency in copper foil presence beneath each symbol on the inner layer is essential.

(3) On PCBs with SMD components, it’s advisable to position three optical symbols at the board corners for three-dimensional alignment (three points define a plane, aiding in solder paste thickness detection).

(4) For imposition, in addition to the three global optical symbols, it’s beneficial to include two or three for imposition at each unit board’s diagonal corners.

(5) Local optical symbols should be placed at diagonal corners for components like QFP with lead center distances ≤0.5mm and BGA with ≤0.8mm.

(6) If components are mounted on both sides, optical symbols must be placed on each side.

(7) If no positioning hole exists on the PCB, the optical symbol’s center should be more than 6.5mm from the transmission edge. If a positioning hole is present, the symbol should be positioned near the center of the PCB on the side of the hole.