The emergence of lead-free PCB boards has introduced new challenges for in-circuit testing (ICT). This paper explores the current PCB surface treatment processes and assesses their impact on ICT. It emphasizes that the key factor affecting ICT is the reliability of probe and ICT contact points. Specific adjustments required during PCB construction to meet ICT standards are outlined. Traditionally, the primary concern of test engineers has been ensuring the efficacy of their test programs in production. “In-Circuit Test (ICT)” remains a highly effective method for identifying manufacturing defects. Advanced ICT systems can enhance test functionality by enabling programming of Flash memory, PLD, FPGA, and EEPROM during testing. The Agilent 3070 system is widely used in ICT. ICT continues to play a crucial role in the manufacturing and testing of printed circuit board assemblies (PCAs), but how will the shift towards lead-free PCBs impact the ICT phase? The push for lead-free soldering technology has sparked significant research into PCB surface treatment methods. However, these studies primarily focus on technical performance during PCB construction, often overlooking the effects of different surface treatment techniques on the testing phase beyond contact resistance. This article will delve into the observed impacts on ICT and the necessity to address and comprehend these changes.

The purpose of this article is to share experience in PCB board surface treatment and to train engineers to implement changes in ICT PCB production process requirements. This article will address the issue of surface preparation on lead-free PCBs, especially at the ICT stage of the manufacturing process, and reveal that successful testing of lead-free surfaces also relies on the beneficial contributions of the PCB construction process. A successful ICT test is always on the physical properties of the contact points between the test probes of the bed of needles fixture and the test pads on the PCB. When a very sharp probe touches a soldered test point, the solder will sink because the contact pressure of the probe is much higher than the yield strength of the solder. As the solder is recessed, the probe passes through any impurities on the surface of the test pad. The uncontaminated solder underneath now touches the probe to make good contact with the test point. The depth of probe insertion is a direct function of the yield strength of the target material. The deeper the probe penetrates, the better the contact. An 8-ounce (oz) probe can apply contact pressures ranging from 26,000 to 160,000 psi (pounds per square inch), depending on the surface diameter. Because the yield strength of the solder is about 5,000 psi, the probe contacts are better for this relatively soft solder.

Selection of PCB surface treatment process

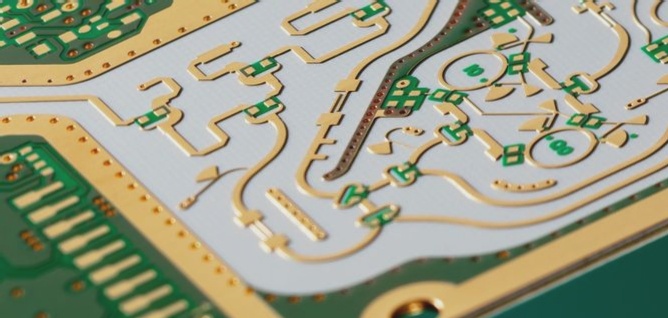

Before we understand the cause and effect, it’s important to describe the types of PCB surface treatments available and what they can offer. All printed circuit boards (PCBs) have copper layers on the board that will oxidize and be damaged if left unprotected. There are a variety of different protective layers that can be used, the common ones are Hot Air Solder Levelling (HASL), Organic Solder Protection (OSP), Electroless Nickel Gold Immersion (ENIG), Silver Immersion, and Tin Immersion.

Hot Air Solder Levelling (HASL)

HASL is the predominant leaded surface treatment process used in industry. The process is formed by immersing the circuit board in a lead-tin alloy, and the excess solder is removed by the “air knife”, which is the hot air blowing on the surface of the board. For the PCA process, HASL has many advantages: it is a PCB board, and the surface layer can be soldered after repeated reflow, cleaning, and storage. For ICT, HASL also provides automatic solder coverage of test pads and vias. However, the HASL surface is poor in flatness or coplanarity compared to existing alternative methods. There are some lead-free HASL replacement processes, which are becoming more and more popular due to the natural replacement characteristics of HASL. HASL has been used with good results over the years, but with the advent of “environmentally friendly” green process requirements, the days of this process are numbered. In addition to lead-free issues, increasing board complexity and finer pitches have exposed many limitations of the HASL process. Advantages: Cost PCB surface technology, maintains solderability throughout the manufacturing process, and has no negative impact on ICT. Disadvantages: Lead-based processes are often used, which are now limited and will eventually be eliminated by 2007. For fine pin pitch (<0.64mm) cases, solder bridging, and thickness issues may result. Surface unevenness can cause homogeneity problems in the assembly process.

Organic Solder Protective Agent

Organic Solder Preservatives (OSPs) are used to create a thin, uniform protective layer on the copper surface of a PCB board. This coating protects the circuit from oxidation during storage and assembly operations. This process has been around for a long time, but only recently gained popularity with the search for lead-free technology and fine pitch solutions. OSP has better performance on PCA assembly than HASL in terms of coplanarity and solderability but requires significant process changes to the type of flux and the number of thermal cycles. Careful handling is required because its acidic character degrades OSP performance and makes copper susceptible to oxidation. Assemblers prefer to work with metal surfaces that are more flexible and can withstand more thermal cycling cycles. With the OSP surface treatment, if the test points are not soldered, it will cause contact problems with the bed of needles fixture at the ICT. Simply changing to a sharper probe type to go through the OSP layer will only cause damage and puncture the PCA test vias or test pads. Studies have shown that switching to higher probing forces or changing probe types has little effect on yield. Untreated copper has an order of magnitude higher yield strength than leaded solder, and as a result, will damage the exposed copper test pads. All testability guidelines strongly advise against probing exposed copper directly. When using OSP, a set of OSP rules needs to be defined for the ICT phase. Important rules require that the stencil be opened at the beginning of the PCB process to allow solder paste to be applied to those test pads and vias that the ICT needs to contact. Advantages: Comparable to HASL in unit cost, good coplanarity, lead-free process, improved solderability. Disadvantages: The assembly process requires major changes, probing raw copper surfaces will be detrimental to ICT, over-pointed ICT probes may damage the PCB, require manual precautions, limit ICT testing and reduce test repeatability.

Electroless Nickel Gold Immersion

Electroless Nickel Gold Immersion (ENIG), a coating that is successfully used on many circuit boards, has a flat surface and excellent solderability despite its high unit cost. The main disadvantage is that the electroless nickel layer is fragile and has been found to crack under mechanical stress. This is known in the industry as “black lumps” or “mud cracks”, which has led to some negative press from ENIG. Advantages: good solderability, flat surface, long shelf life, and can withstand multiple reflow soldering. Disadvantages: High cost (about 5 times HASL), “black block” problem, the manufacturing process using cyanide, and some other harmful chemicals.

Silver Immersion

Silver immersion is an added method of surface preparation for PCB boards. Mainly used in Asia, it is being promoted in North America and Europe. During the soldering process, the silver layer melts into the solder joint, leaving a tin/lead/silver alloy on the copper layer that provides a very reliable solder joint for BGA packages. Its contrasting color makes it easy to inspect, and it is also a natural alternative to HASL for welding treatments. Silver immersion is a very promising surfacing process, but as with all new surfacing technologies, end users are very conservative about it. Many manufacturers refer to this process as an “under investigation” process, but it is likely to be the lead-free surface process of choice. Advantages: Good weldability, smooth surface, natural alternative to HASL immersion. Cons: Conservative attitude of end-users means a lack of relevant information in the industry.

Tin Immersion

This is a newer surface treatment process with many similar properties to the silver immersion process. However, there are significant health and safety issues to consider due to precautions against thiourea (possibly a carcinogen) used in the tin immersion process during PCB manufacturing. In addition, migration (the “tin burr” effect) is of concern, although anti-migration chemistries can achieve some success in controlling this problem. Advantages: good weldability, smooth surface, relatively low cost. Cons: Health and safety concerns, the limited number of thermal cycling cycles.

Summary of PCB surface treatment

Taking into account some problems with fixtures and processes, users believe that once these problems are dealt with, the pass yield they can obtain is between 80~90%. The above is the main method of lead-free processing of PCB boards. HASL will remain the widely used PCB board processing process, in this case, nothing will change for test engineers. In some countries, HASL has been banned by law and alternatives have been adopted. As PCA manufacturing expands into more different areas, more and more lead-free processes will be seen in ICT testing. Although OSP is not a natural replacement for HASL, it has become an alternative treatment option being investigated by PCA manufacturers. When no process changes were made to allow solder paste on test pads and vias, this would result in actual ICT Test reliability issues The conclusion is that the process of PCB surface treatment is not perfect, and each method has its own problems that need to be considered. Some of these problems are more serious than others, and all of these lead-free PCB surface preparation processes require modifications in process steps to prevent fixture contact reliability issues at ICT. Comparative Considerations of HASL, OSP, and Silver Immersion in the ICT Phase Now I would like to focus on these surface finishing techniques and how they affect the performance of ICT. The finish leaves soft solder “arcs” and exposed vias at the test points, which are ideal for ICT test objects. A property that HASL has that OSP does not have is force absorption, HASL is a eutectic SnPB, which is particularly soft. This soft target has two benefits: adapting to the probe and absorbing energy. There is no such soft target for OSP PCB boards. In contrast, copper surfaces are very hard and cannot absorb as much energy, so the area of direct contact that the probe can “bite into” is reduced. The copper plating on the outer layer is generally between 10 and 50 microns. Combine the copper plating with the OSP cladding and you will see that the probes used to probe the HASL board will not work on the OSP finish board. Studies have shown that OSP creates a very hard “shell” on the test target during the longer transfer time between reflow and ICT. Delivery time to ICT should be less than 24 hours. There are many other process factors that can affect the degree to which OSP is confusing to the test engineer, some of which are: OSP provider type, number of passes in the reflow oven, whether the wave process is removed, nitrogen reflow or air Reflow, and the type of mock testing at ICT. Direct probing of the copper surface coupled with the higher probe force required to penetrate the OSP layer creates a real potential threat of breaking the thin copper layer and causing internal shorts. Therefore, our recommendation is to never probe exposed copper surfaces. Recent examples have shown that board vias or test points can be punctured after 5 to 10 fixture excitations. For some PCA manufacturers, the impact of OSP on ICT is so problematic that they have moved away from OSP altogether. Other manufacturers are starting to learn how to follow the “OSP Rules” listed below. “OSP Rules” for ICT Test Fixtures and Procedures: Has a high impact on Through Yield (FPY); may require changing fixture probes for higher force, e.g. from 2N to 3N; may require changing fixtures Probe type, changed to a more pointed type; may require a “double-click” gripper excitation method, or utilize pneumatics, manipulators; simulation test program constraints may need to be compromised, open, or even ignored; research suggests these asterisked rules With potentially relatively little impact on yield, the way to ensure reliable test contact is to ensure that the test pads are soldered. Some manufacturers see immediate cost savings from OSP and see it as an alternative to lead-free processes. However, some companies have recently taken a complete turnaround and are re-examining their strategies when considering the real costs associated with production disruptions and delays.

Silver Immersion

The silver immersion is a 0.4 to 0.8 micron metal layer on top of the copper layer that provides the “meat” that the test probes can bite into. Silver immersion is not as widely used as HASL or OSP, but initial research suggests that it is a natural alternative to HASL as a manufacturing process. There have been some preliminary studies of ICT reliability, which have shown that etch time (surface roughness/finish) and surface thickness are important considerations for repeatability. There is no problem with the contact reliability of the jig with silver surface treatment in the ICT stage, so the test jig does not need to be adjusted, but the probe or the test software should be adjusted. The etch rate is important for ICT testing because it determines whether the silver finish will be shiny or dull. During the silver deposition step, silver is deposited onto the contours of the copper surface, so if the roughness of the surface increases, and thus the area, it appears as a dull surface, while a surface with roughness appears as a bright surface. Industry research into this surfacing process is very limited but appears technically and commercially promising. Recent experience has shown that this surface treatment presents no problems for ICT. PCB board manufacturers now offer silver finish boards at the same price as HASL products.

Summary of this article

It looks like the trend for some companies is that OSP is seen as a natural replacement for HASL. This choice likely stemmed from the recognition of unit cost savings. ICT engineers should pay attention to this trend: OSP-coated PCBs will not perform as well as other alternative lead-free finishes unless the test pads are covered with solder. If the process flow is not changed, the potential savings in initial cost may be offset by the cost of changing fixture probes, fixture maintenance, modifying test software, and scrap that damages the board. We see a lot of the opposite happening in OSP selection. Advice to customers who have not abandoned the leaded HASL process is to consider the advantages and disadvantages of all possible lead-free PCB alternative processes, ensuring that all manufacturing stages are covered in trials, including testing, for silver PCB board we do not have any conclusive results on the impact of surface treatment processes on ICT. We have discussed with customers who use the silver finish and they have not noticed any gripper contact issues using this finish.

The purpose of this article is to share experience in PCB board surface treatment and to train engineers to implement changes in ICT PCB production process requirements. This article will address the issue of surface preparation on lead-free PCBs, especially at the ICT stage of the manufacturing process, and reveal that successful testing of lead-free surfaces also relies on the beneficial contributions of the PCB construction process. A successful ICT test is always on the physical properties of the contact points between the test probes of the bed of needles fixture and the test pads on the PCB. When a very sharp probe touches a soldered test point, the solder will sink because the contact pressure of the probe is much higher than the yield strength of the solder. As the solder is recessed, the probe passes through any impurities on the surface of the test pad. The uncontaminated solder underneath now touches the probe to make good contact with the test point. The depth of probe insertion is a direct function of the yield strength of the target material. The deeper the probe penetrates, the better the contact. An 8-ounce (oz) probe can apply contact pressures ranging from 26,000 to 160,000 psi (pounds per square inch), depending on the surface diameter. Because the yield strength of the solder is about 5,000 psi, the probe contacts are better for this relatively soft solder.

Selection of PCB surface treatment process

Before we understand the cause and effect, it’s important to describe the types of PCB surface treatments available and what they can offer. All printed circuit boards (PCBs) have copper layers on the board that will oxidize and be damaged if left unprotected. There are a variety of different protective layers that can be used, the common ones are Hot Air Solder Levelling (HASL), Organic Solder Protection (OSP), Electroless Nickel Gold Immersion (ENIG), Silver Immersion, and Tin Immersion.

Hot Air Solder Levelling (HASL)

HASL is the predominant leaded surface treatment process used in industry. The process is formed by immersing the circuit board in a lead-tin alloy, and the excess solder is removed by the “air knife”, which is the hot air blowing on the surface of the board. For the PCA process, HASL has many advantages: it is a PCB board, and the surface layer can be soldered after repeated reflow, cleaning, and storage. For ICT, HASL also provides automatic solder coverage of test pads and vias. However, the HASL surface is poor in flatness or coplanarity compared to existing alternative methods. There are some lead-free HASL replacement processes, which are becoming more and more popular due to the natural replacement characteristics of HASL. HASL has been used with good results over the years, but with the advent of “environmentally friendly” green process requirements, the days of this process are numbered. In addition to lead-free issues, increasing board complexity and finer pitches have exposed many limitations of the HASL process. Advantages: Cost PCB surface technology, maintains solderability throughout the manufacturing process, and has no negative impact on ICT. Disadvantages: Lead-based processes are often used, which are now limited and will eventually be eliminated by 2007. For fine pin pitch (<0.64mm) cases, solder bridging, and thickness issues may result. Surface unevenness can cause homogeneity problems in the assembly process.

Organic Solder Protective Agent

Organic Solder Preservatives (OSPs) are used to create a thin, uniform protective layer on the copper surface of a PCB board. This coating protects the circuit from oxidation during storage and assembly operations. This process has been around for a long time, but only recently gained popularity with the search for lead-free technology and fine pitch solutions. OSP has better performance on PCA assembly than HASL in terms of coplanarity and solderability but requires significant process changes to the type of flux and the number of thermal cycles. Careful handling is required because its acidic character degrades OSP performance and makes copper susceptible to oxidation. Assemblers prefer to work with metal surfaces that are more flexible and can withstand more thermal cycling cycles. With the OSP surface treatment, if the test points are not soldered, it will cause contact problems with the bed of needles fixture at the ICT. Simply changing to a sharper probe type to go through the OSP layer will only cause damage and puncture the PCA test vias or test pads. Studies have shown that switching to higher probing forces or changing probe types has little effect on yield. Untreated copper has an order of magnitude higher yield strength than leaded solder, and as a result, will damage the exposed copper test pads. All testability guidelines strongly advise against probing exposed copper directly. When using OSP, a set of OSP rules needs to be defined for the ICT phase. Important rules require that the stencil be opened at the beginning of the PCB process to allow solder paste to be applied to those test pads and vias that the ICT needs to contact. Advantages: Comparable to HASL in unit cost, good coplanarity, lead-free process, improved solderability. Disadvantages: The assembly process requires major changes, probing raw copper surfaces will be detrimental to ICT, over-pointed ICT probes may damage the PCB, require manual precautions, limit ICT testing and reduce test repeatability.

Electroless Nickel Gold Immersion

Electroless Nickel Gold Immersion (ENIG), a coating that is successfully used on many circuit boards, has a flat surface and excellent solderability despite its high unit cost. The main disadvantage is that the electroless nickel layer is fragile and has been found to crack under mechanical stress. This is known in the industry as “black lumps” or “mud cracks”, which has led to some negative press from ENIG. Advantages: good solderability, flat surface, long shelf life, and can withstand multiple reflow soldering. Disadvantages: High cost (about 5 times HASL), “black block” problem, the manufacturing process using cyanide, and some other harmful chemicals.

Silver Immersion

Silver immersion is an added method of surface preparation for PCB boards. Mainly used in Asia, it is being promoted in North America and Europe. During the soldering process, the silver layer melts into the solder joint, leaving a tin/lead/silver alloy on the copper layer that provides a very reliable solder joint for BGA packages. Its contrasting color makes it easy to inspect, and it is also a natural alternative to HASL for welding treatments. Silver immersion is a very promising surfacing process, but as with all new surfacing technologies, end users are very conservative about it. Many manufacturers refer to this process as an “under investigation” process, but it is likely to be the lead-free surface process of choice. Advantages: Good weldability, smooth surface, natural alternative to HASL immersion. Cons: Conservative attitude of end-users means a lack of relevant information in the industry.

Tin Immersion

This is a newer surface treatment process with many similar properties to the silver immersion process. However, there are significant health and safety issues to consider due to precautions against thiourea (possibly a carcinogen) used in the tin immersion process during PCB manufacturing. In addition, migration (the “tin burr” effect) is of concern, although anti-migration chemistries can achieve some success in controlling this problem. Advantages: good weldability, smooth surface, relatively low cost. Cons: Health and safety concerns, the limited number of thermal cycling cycles.

Summary of PCB surface treatment

Taking into account some problems with fixtures and processes, users believe that once these problems are dealt with, the pass yield they can obtain is between 80~90%. The above is the main method of lead-free processing of PCB boards. HASL will remain the widely used PCB board processing process, in this case, nothing will change for test engineers. In some countries, HASL has been banned by law and alternatives have been adopted. As PCA manufacturing expands into more different areas, more and more lead-free processes will be seen in ICT testing. Although OSP is not a natural replacement for HASL, it has become an alternative treatment option being investigated by PCA manufacturers. When no process changes were made to allow solder paste on test pads and vias, this would result in actual ICT Test reliability issues The conclusion is that the process of PCB surface treatment is not perfect, and each method has its own problems that need to be considered. Some of these problems are more serious than others, and all of these lead-free PCB surface preparation processes require modifications in process steps to prevent fixture contact reliability issues at ICT. Comparative Considerations of HASL, OSP, and Silver Immersion in the ICT Phase Now I would like to focus on these surface finishing techniques and how they affect the performance of ICT. The finish leaves soft solder “arcs” and exposed vias at the test points, which are ideal for ICT test objects. A property that HASL has that OSP does not have is force absorption, HASL is a eutectic SnPB, which is particularly soft. This soft target has two benefits: adapting to the probe and absorbing energy. There is no such soft target for OSP PCB boards. In contrast, copper surfaces are very hard and cannot absorb as much energy, so the area of direct contact that the probe can “bite into” is reduced. The copper plating on the outer layer is generally between 10 and 50 microns. Combine the copper plating with the OSP cladding and you will see that the probes used to probe the HASL board will not work on the OSP finish board. Studies have shown that OSP creates a very hard “shell” on the test target during the longer transfer time between reflow and ICT. Delivery time to ICT should be less than 24 hours. There are many other process factors that can affect the degree to which OSP is confusing to the test engineer, some of which are: OSP provider type, number of passes in the reflow oven, whether the wave process is removed, nitrogen reflow or air Reflow, and the type of mock testing at ICT. Direct probing of the copper surface coupled with the higher probe force required to penetrate the OSP layer creates a real potential threat of breaking the thin copper layer and causing internal shorts. Therefore, our recommendation is to never probe exposed copper surfaces. Recent examples have shown that board vias or test points can be punctured after 5 to 10 fixture excitations. For some PCA manufacturers, the impact of OSP on ICT is so problematic that they have moved away from OSP altogether. Other manufacturers are starting to learn how to follow the “OSP Rules” listed below. “OSP Rules” for ICT Test Fixtures and Procedures: Has a high impact on Through Yield (FPY); may require changing fixture probes for higher force, e.g. from 2N to 3N; may require changing fixtures Probe type, changed to a more pointed type; may require a “double-click” gripper excitation method, or utilize pneumatics, manipulators; simulation test program constraints may need to be compromised, open, or even ignored; research suggests these asterisked rules With potentially relatively little impact on yield, the way to ensure reliable test contact is to ensure that the test pads are soldered. Some manufacturers see immediate cost savings from OSP and see it as an alternative to lead-free processes. However, some companies have recently taken a complete turnaround and are re-examining their strategies when considering the real costs associated with production disruptions and delays.

Silver Immersion

The silver immersion is a 0.4 to 0.8 micron metal layer on top of the copper layer that provides the “meat” that the test probes can bite into. Silver immersion is not as widely used as HASL or OSP, but initial research suggests that it is a natural alternative to HASL as a manufacturing process. There have been some preliminary studies of ICT reliability, which have shown that etch time (surface roughness/finish) and surface thickness are important considerations for repeatability. There is no problem with the contact reliability of the jig with silver surface treatment in the ICT stage, so the test jig does not need to be adjusted, but the probe or the test software should be adjusted. The etch rate is important for ICT testing because it determines whether the silver finish will be shiny or dull. During the silver deposition step, silver is deposited onto the contours of the copper surface, so if the roughness of the surface increases, and thus the area, it appears as a dull surface, while a surface with roughness appears as a bright surface. Industry research into this surfacing process is very limited but appears technically and commercially promising. Recent experience has shown that this surface treatment presents no problems for ICT. PCB board manufacturers now offer silver finish boards at the same price as HASL products.

Summary of this article

It looks like the trend for some companies is that OSP is seen as a natural replacement for HASL. This choice likely stemmed from the recognition of unit cost savings. ICT engineers should pay attention to this trend: OSP-coated PCBs will not perform as well as other alternative lead-free finishes unless the test pads are covered with solder. If the process flow is not changed, the potential savings in initial cost may be offset by the cost of changing fixture probes, fixture maintenance, modifying test software, and scrap that damages the board. We see a lot of the opposite happening in OSP selection. Advice to customers who have not abandoned the leaded HASL process is to consider the advantages and disadvantages of all possible lead-free PCB alternative processes, ensuring that all manufacturing stages are covered in trials, including testing, for silver PCB board we do not have any conclusive results on the impact of surface treatment processes on ICT. We have discussed with customers who use the silver finish and they have not noticed any gripper contact issues using this finish.