Introduction:

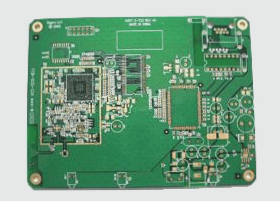

A Printed Circuit Board (PCB) is a crucial element in electronic devices, acting as a platform for electronic components and a conduit for circuits. PCB technology has advanced over time, with single-sided, double-sided, and multi-layer PCBs being common variants. Presently, PCB technology has reached a sophisticated level with ongoing enhancements and refinements.

High-Density Interconnection (HDI) PCB:

In the early 1990s, High-Density Interconnection (HDI) technology emerged, pioneered by Japan and the United States. HDI PCBs utilize double-sided or multi-layer boards as core substrates and employ multi-layer stacking techniques to create densely interconnected printed circuit boards with high integrity.

Key features of HDI PCBs include:

- Miniaturization

- Thinness

- High-frequency operation

- Fine traces and vias

- Efficient heat dissipation

Continuous technological progress drives the evolution of HDI PCBs, with “thinness” serving as a foundational aspect facilitating miniaturization. The capability to produce fine traces, microvias, and effective insulation layers directly impacts the PCB’s suitability for high-frequency operation and optimal thermal performance, crucial for ultra-high-density electronic circuits.

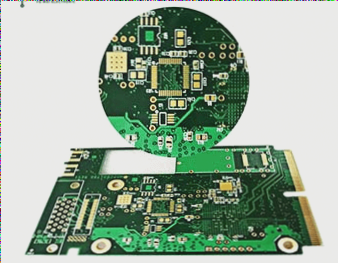

High-Density Any Layer Interconnect PCB:

HDI PCBs with diverse hierarchical structures necessitate complex manufacturing processes. The more layers and connections involved, the higher the manufacturing complexity. Key connection methods for these PCBs include ladder connection, staggered connection, and span connection. Ultra-high-density interconnect PCBs represent the forefront of PCB technology and find increasing application in compact, lightweight, and multifunctional products like smartphones, laptops, digital cameras, and LCD TVs.

Integrated Printed Circuit Board:

Integrated PCB technology integrates electronic components directly into the PCB structure, enhancing functionality, reliability, and signal transmission performance of electronic systems. This integration reduces production costs and aligns with eco-friendly manufacturing practices, playing a crucial role in shrinking electronic systems and offering substantial market potential.

Metal Substrates with High Heat Dissipation:

For more efficient heat dissipation, metal substrates are utilized in PCBs. This feature is essential for electronic devices that generate significant heat during operation, ensuring optimal performance and longevity.

Metal PCBs for Efficient Heat Dissipation

- High thermal conductivity metal substrates are crucial for dissipating heat from high-power components.

- Efficient heat dissipation is influenced by the multi-chip package layout and component packaging reliability.

- Metal PCBs compatible with Surface Mount Technology (SMT) offer advantages like reduced product sizes, lower costs, and greater rigidity compared to ceramic substrates.

- These features make metal PCBs highly competitive for various applications.

High-Frequency and High-Speed PCBs

High-frequency and high-speed PCBs have been essential since the late 20th century, initially for military applications. The demand for these PCBs has surged with the transition of high-frequency communication bands to civilian use, driving advancements in information transmission technologies. They play a critical role in long-distance communication, telemedicine, and logistics warehouse automation.

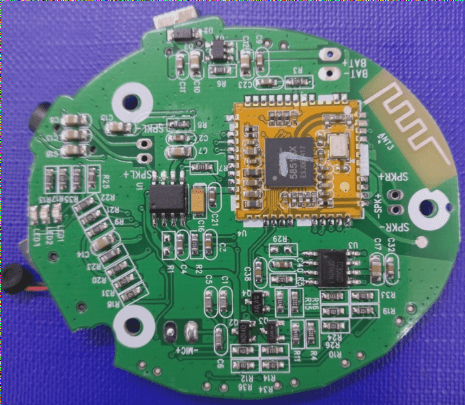

Rigid-Flex PCBs for Compact Devices

The increasing demand for high-performance, multi-functional, and compact electronic devices has led to a rise in miniaturized and high-density PCBs. Rigid-flex PCBs, combining rigid PCBs and flexible circuits (FPCs), maximize limited space in portable devices like digital cameras, smartphones, and other mobile electronics. These PCBs eliminate the need for connectors, offer excellent mounting properties, and enable more compact designs.

Conclusion: Advanced PCB Technologies

Metal, high-frequency, and rigid-flex PCB technologies represent the most advanced solutions available today. As electronic technologies evolve, further innovations and improvements in PCB manufacturing processes are expected.

If you have any questions about PCBs or PCBA, please don’t hesitate to contact me at info@wellcircuits.com.