Reverse Engineering and Repair Techniques in PCBA Assembly

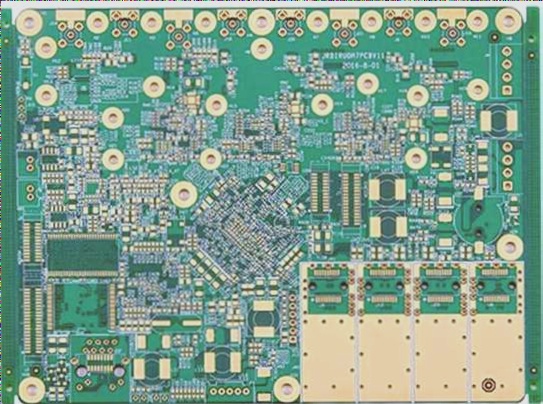

Reverse engineering is the process of dissecting a product to understand its inner workings, enabling the recreation or enhancement of the original design. In the realm of PCBA assembly, this method is utilized to pinpoint component functions, map out schematic diagrams, and effectively troubleshoot and rectify any potential issues.

Repair Techniques

- Component Identification: Repair involves the identification of faulty components, employing soldering and desoldering methods, and utilizing diagnostic tools like multimeters and oscilloscopes.

- Technical Expertise: Repair technicians must possess a profound grasp of electronics and the ability to decipher schematics to diagnose and resolve problems accurately.

Key Aspects of PCBA Assembly

Aside from technical prowess, successful reverse engineering and repair in PCBA assembly demand meticulous attention to detail, patience, and a systematic approach. Technicians are urged to meticulously document their findings and repair procedures to ensure comprehensive analysis and favorable outcomes.

Component Replacement

In scenarios where components require replacement, meticulous removal of the defective part and precise soldering of a new component are essential steps in the repair process.

Trace Repair

When traces on the PCB are damaged, meticulous rerouting of connections using solder or conductive ink can effectively restore functionality.

Cleaning and Inspection

Post-repair, thorough cleaning of the PCB to eliminate flux residue and contaminants is crucial. A detailed inspection should follow to confirm the success of the repair and detect any lingering issues.

Additional Steps in Repair

- Troubleshooting: Utilizing test equipment like multimeters and oscilloscopes is vital to pinpoint and resolve circuit issues.

- Cleaning and Maintenance: Regular cleaning and maintenance are imperative to extend the lifespan of electronic devices.

- Firmware Upgrade: In some cases, firmware updates are necessary to address issues and boost device performance.

- Data Backup and Recovery: Safeguarding data integrity through backup and recovery processes is essential for devices with storage capabilities.