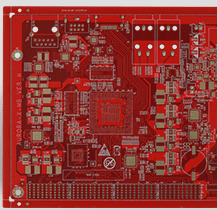

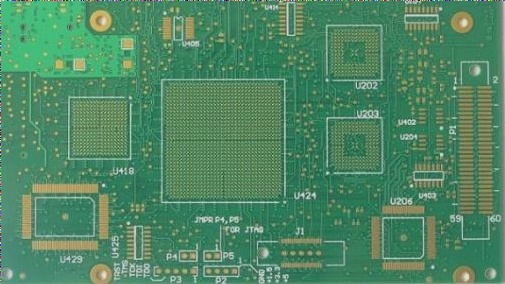

PCB Boards Overview

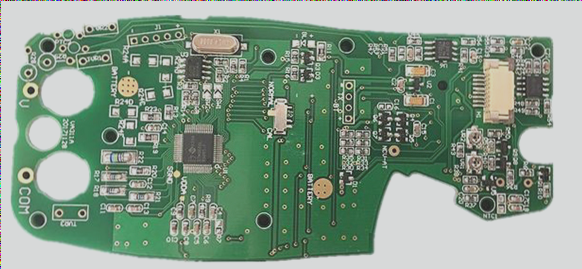

- PCB boards come in single-layer, double-layer, and multi-layer options.

- Single-layer PCBs have components on one side and wiring on the other.

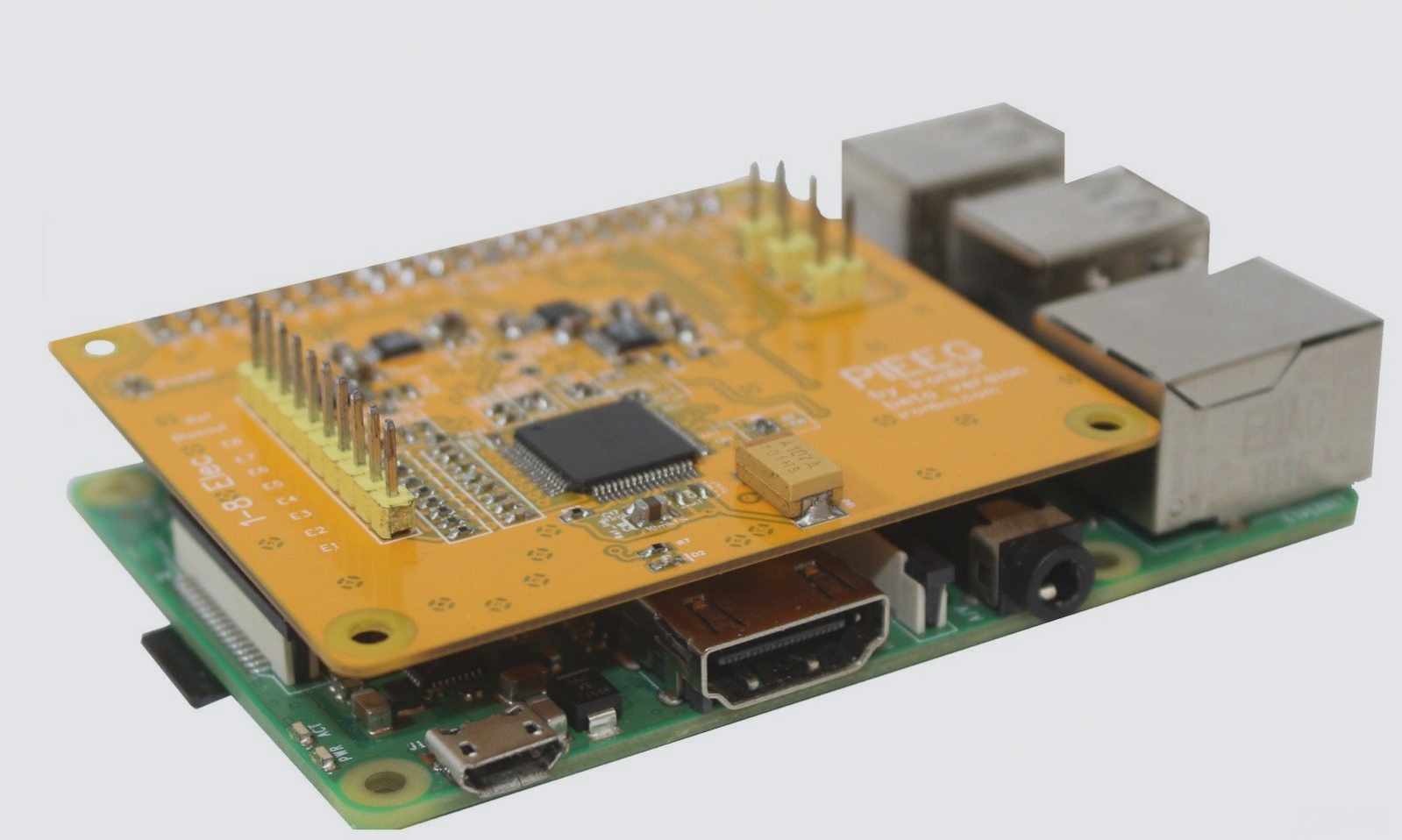

- Double-layer PCBs are two single-layer boards stacked together.

- Multi-layer PCBs have multiple layers with vias connecting them.

Types of PCB Layers

- Single-layer PCB: Components on one side, wiring on the other.

- Double-layer PCB: Components and wiring on both sides.

- Multi-layer PCB: More layers for complex circuits, with ground and power layers.

Manufacturing Process

- Complex manufacturing process involving rolling, cutting, etching, and more.

- Layers include component surface, power layer, ground layer, and solder pressure layer.

- Quality checks ensure proper bonding and avoid short circuits.

Copper Wiring Process

The copper wiring process involves transferring the working film onto the metal conductor using various methods:

- Negative film transfer method: Applies copper foil and removes excess material.

- Positive photoresist method: Uses sensitizer and UV light to create wiring patterns.

- Etching: Removes exposed copper to form the final wiring layout.

PCB Design Best Practices

1. Trace Width and Current Handling

- Minimum trace width should be at least 0.2mm (8mil).

- For high-density PCBs, aim for a trace pitch and width of around 0.3mm (12mil).

- With a copper foil thickness of approximately 50µm, the trace width should range from 1–1.5mm (60mil) to support currents up to 2A.

- Commonly, 80mil traces are used, especially in applications involving microprocessors.

2. High-Speed PCB Frequency Considerations

- A signal is deemed high-speed when its rise/fall time is less than 3–6 times the signal’s transmission time.

- For digital circuits, focus on the steepness of the signal edge, particularly the rise and fall times.

- Referencing *High-Speed Digital Design*, a signal is high-speed if it rises from 10% to 90% of its maximum amplitude in less than six times the trace delay.

- Even an 8kHz square wave can be high-speed if the signal edges are sharp, requiring application of transmission line theory during routing.

3. Power and Ground Layout Tips

- Keep power traces short and direct, ideally in a tree structure rather than a loop.

- Ground loop issues in digital circuits typically result in minimal voltage drops, usually not affecting circuit operation adversely.

- Utilizing a 2Gsps oscilloscope to measure ground currents reveals insights into pulse width and potential differences between ground points.

- Separating analog ground loops on the PCB can mitigate frequency interference from space and improve circuit performance.

- Addressing humming in amplifier outputs may involve cutting ground loops, as observed in high-end “Hi-Fi” devices.

If you require PCB manufacturing services or have any inquiries, feel free to contact me.