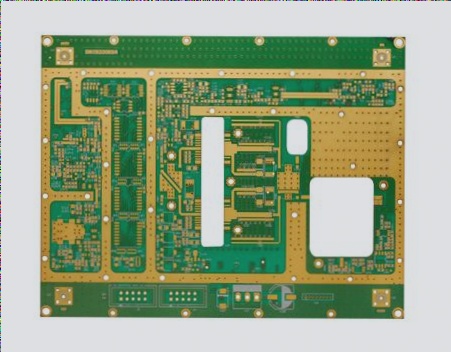

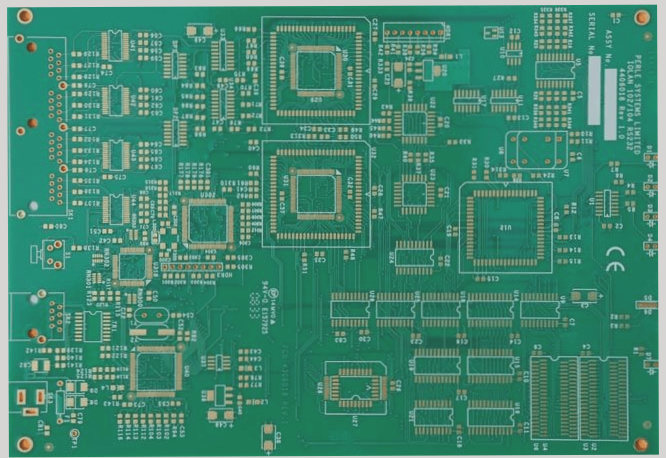

1. Santa Clara, California, USA, August 1, 2007—Verdant Electronics announced today that they are developing a groundbreaking technology poised to transform PCB manufacturing and assembly, significantly enhancing the electronic product manufacturing process. This innovative approach is currently seeking patent protection.

2. This novel method greatly minimizes the steps involved in electronic assembly, streamlining the PCB manufacturing and assembly processes while also reducing costs and boosting reliability.

3. A new supply chain model

4. The core concept of this technology employs a methodology that starkly contrasts with traditional approaches to circuit interconnection assembly and manufacturing.

5. The implications of this alternative manufacturing process for interconnection circuits are profound and far-reaching. Currently, electronic manufacturing encompasses three components: PCB boards, electronic components, and assembly. This new method condenses the entire process into two parts, as PCB manufacturing and assembly merge into a continuous workflow.

6. A breakthrough in environmental protection—lead-free, solder-free assembly

7. Verdant Electronics’ innovative concept eradicates many inefficient steps in PCB manufacturing and assembly. A significant advantage is the removal of solder from the assembly process, aligning with the industry’s ongoing commitment to transition towards lead-free soldering.

1. The new method developed by Verdant Electronics will eliminate the challenges associated with manufacturing lead-free electronic products, while consuming less energy and raw materials. It avoids restricted substances and enables the production of electronic devices that are smaller, lighter, more affordable, and more durable. This technology exemplifies a commitment to green practices, aligning perfectly with the global push for environmentally friendly electronics.

2. In response to industry authority feedback, Joseph (Joe) Fjelstad, founder of Verdant Electronics and the creator of this innovative technology, shared: “The insights from experts who have assessed this technology have truly delighted me. They expressed strong support for this concept, and crucially, they offered valuable opinions and suggestions to further its development and application, leveraging existing materials and equipment.”

3. Fjelstad elaborated: “This technology builds on advancements made by GE and other manufacturers in the 1990s for microelectronics, such as IC and module packaging. Although the original technology faced low yield rates that hindered widespread adoption, the incorporation of tested and sintered IC packages shifts the yield rate issue to align with traditional PCB soldering methods, allowing for a straightforward resolution.”

4. Fjelstad emphasized: “Simplicity is central to this approach. As 14th-century monk philosopher William of Occam stated, ‘Entities should not be multiplied beyond necessity.’ This principle of clarity and simplicity has now become a foundational tenet for Verdant Electronics.”