Enhancing Anti-Interference Capabilities in RF Circuit PCB Design

Radio frequency (RF) PCBs face challenges such as skin effect, coupling, and interference. Balancing factors like mutual interference, power supply noise, and grounding disruptions is crucial for successful PCB design. Here are some techniques to enhance anti-interference capabilities:

Component Layout on Multilayer Boards

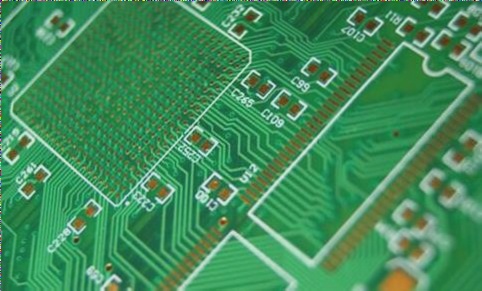

- Secure components along the RF path to minimize its length.

- Position input away from output and maintain separation between high-power and low-power circuits.

- Isolate sensitive analog signals from high-speed digital and RF signals.

Component Layout Techniques

- Linear Layout for RF Main Signal Components: Opt for a linear layout whenever possible. Avoid U-shaped layouts to maintain a separation of at least 1.5cm between input and output.

- One-Line Layout: Strategically place components for signal integrity, thermal management, and ease of assembly. Minimize signal paths to reduce interference and enhance efficiency.

- Thermal Management: Position heat-generating components strategically for effective dissipation.

- 45-Degree Layout: Arrange devices at a 45-degree angle to minimize RF line length.

Wiring Requirements

For optimal performance:

- Keep RF signal traces short and straight.

- Minimize abrupt changes in line direction.

- Reduce the number of vias and avoid intersections with other signal lines.

- Add ground vias around RF signal lines when possible.

Consider these optimization methods to enhance your RF circuit PCB design.

Additional Information

For more insights on PCB fabrication and design, visit wellcircuits.com.

Arc Line Design for PCB Layout Optimization

When designing a PCB layout, if the radio frequency line cannot be straight, consider treating it as an arc line. This approach can help reduce external radiation and mutual coupling of the RF signal. Experiments have shown that bending the corners of the transmission line at right angles can minimize return loss.

Ground Wire and Power Plane Considerations

- Make the ground wire as thick as possible to ensure effective grounding.

- Extensively ground each layer of the PCB and connect them to the main ground.

- Use additional ground vias to minimize ground impedance.

- Avoid dividing the power supply of the RF circuit into planes to reduce radiation and susceptibility to interference.

- Route power lines in an elongated strip shape tailored to current requirements.

Optimizing Signal Routing

- Ensure power lines and ground lines run parallel to the RF signal direction without overlapping.

- Use a vertical cross configuration at intersections of power and ground lines.

- Isolate RF signals and IF signals with a ground whenever possible.

Effective Signal Processing and Isolation

Packetizing the processing of radio frequency signals, interference sources, and other critical signals enhances signal immunity to interference. It’s crucial to ensure effective isolation between RF units of different modules with cavities.

Copper Foil Processing and RF Line Width

- Maintain a smooth and uniform surface for copper foil processing.

- Ensure the RF line has a minimum width of 3W measured from the adjacent ground plane.

Optimal Spacing and Shielding Cavities

For optimal performance, ground RF lines within the same layer and maintain proper spacing between holes. Shielding cavities should be fashioned into a regular shape with arc-shaped corners for ease of casting.

Shielding Cavity Design

- Seal the periphery of the shielding cavity and introduce interface lines using strip or microstrip lines.

- Process the joints of different cavities with grooves for better integration.

- Reinforce support by placing equally spaced metalized holes along the cavity.

By following these design principles and optimization techniques, you can enhance the performance and reliability of your PCB layout for radio frequency applications.