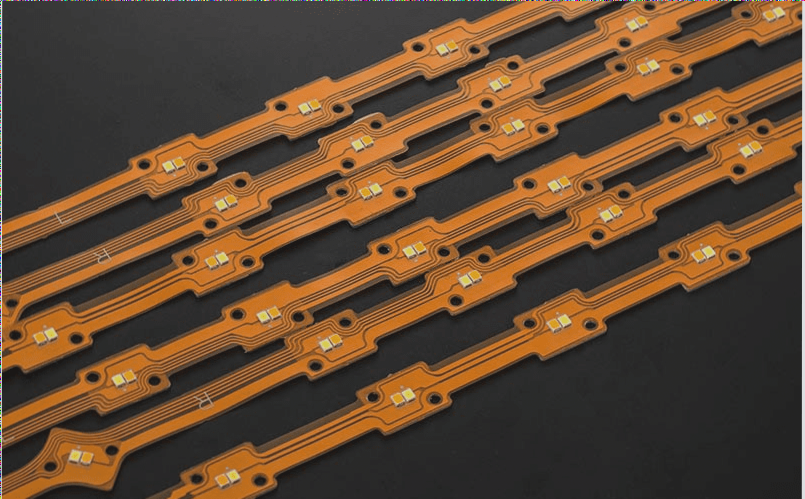

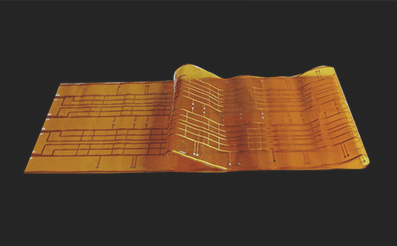

2. Common materials for rigid PCBs include phenolic paper laminate, epoxy paper laminate, polyester glass mat laminate, and epoxy glass cloth laminate. Flexible PCBs, on the other hand, typically use materials such as polyester film, polyimide amine film, and fluorinated ethylene propylene (FEP) film.

3. When classified by the number of circuit layers, PCBs are divided into single-sided, double-sided, and multi-layer boards. The most common multi-layer boards are typically 4-layer or 6-layer, though more complex designs can feature dozens of layers.

4. **Single-Sided Boards**

Single-sided PCBs have components placed on one side, with the wiring concentrated on the other side (in designs where SMD components share the same side as the wiring, the through-hole components will be on the opposite side). Because the wiring is restricted to a single side, this type of PCB is referred to as single-sided. Due to the constraints on circuit design—since only one side is available for routing and no overlapping of traces is allowed—this type of PCB was primarily used in earlier circuits.

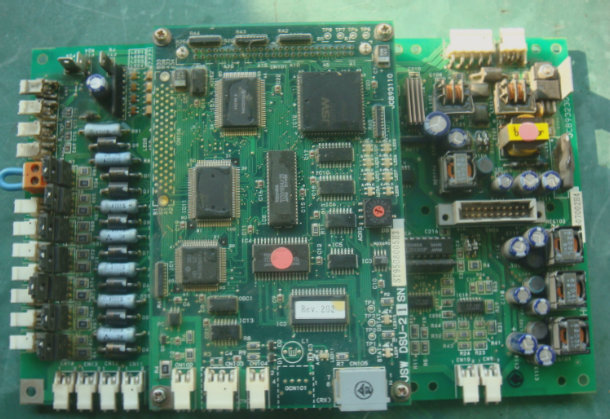

5. **Double-Sided Boards**

**PCB Double-Sided Board**

This type of circuit board features wiring on both sides. To use wiring on both surfaces, there must be an appropriate connection between the two sides. The “bridge” that connects these circuits is called a via. A via is a small hole filled or coated with metal, allowing for electrical connections between the two sides of the PCB. Since the area of a double-sided board is twice as large as that of a single-sided board, it helps overcome the challenge of interlacing wires on a single-sided board (by routing the connection to the other side through vias). This makes it better suited for more complex circuits than a single-sided board.

—

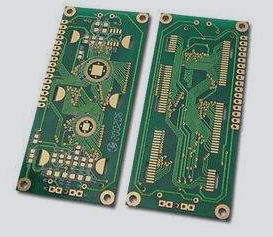

**Multilayer Board**

**Multilayer Boards**

To increase the available wiring area, multilayer boards incorporate multiple single- or double-sided wiring layers. Typically, a double-sided board is used as the inner layer, while two single-sided boards serve as the outer layers. In some cases, two double-sided boards are used as the inner layers with two single-sided boards as the outer layers. These layers are alternately bonded with insulating material and interconnected based on the design requirements, forming four-layer or six-layer printed circuit boards, commonly referred to as multilayer PCBs. The number of layers in a PCB does not always correspond to the number of independent wiring layers, as sometimes void layers are included to control the board’s thickness. Typically, multilayer boards have an even number of layers, including the outer two. Most motherboards feature 4 to 8 layers, though technically, PCBs can have up to 100 layers. High-end supercomputers often use very high-layer-count motherboards, but due to the rise of cluster-based computing, these super-multilayer boards have become less common. Since the various layers are tightly integrated, it’s generally difficult to discern the exact number of layers, though a careful inspection of the motherboard may reveal them.

—

**Features**

The widespread use of PCBs can be attributed to their numerous unique advantages, which can be summarized as follows:

– **High Density:** Over the decades, the high density of printed boards has advanced in tandem with improvements in integrated circuit technology and mounting techniques.

– **High Reliability:** With rigorous inspection, testing, and aging processes, PCBs can operate reliably over long periods, often up to 20 years.

– **Design Flexibility:** PCB designs can be tailored to meet specific performance requirements (electrical, physical, chemical, mechanical, etc.) through standardization and optimization, enabling quick and efficient development.

– **Manufacturability:** Modern management practices enable the mass production of PCBs using standardized, automated processes, ensuring consistent product quality.

– **Testability:** A comprehensive set of testing methods, standards, equipment, and instruments are available to assess the eligibility and lifespan of PCB products.

– **Assembly Compatibility:** PCBs facilitate standardized component assembly, supporting automation and large-scale production. They can also be integrated with other components to form larger systems, even complete machines.

– **Maintainability:** Due to the large-scale production and standardization of PCB components, replacement parts can be quickly and easily swapped out, allowing for fast system restoration. Additional benefits include system miniaturization, weight reduction, and enhanced high-speed signal transmission.