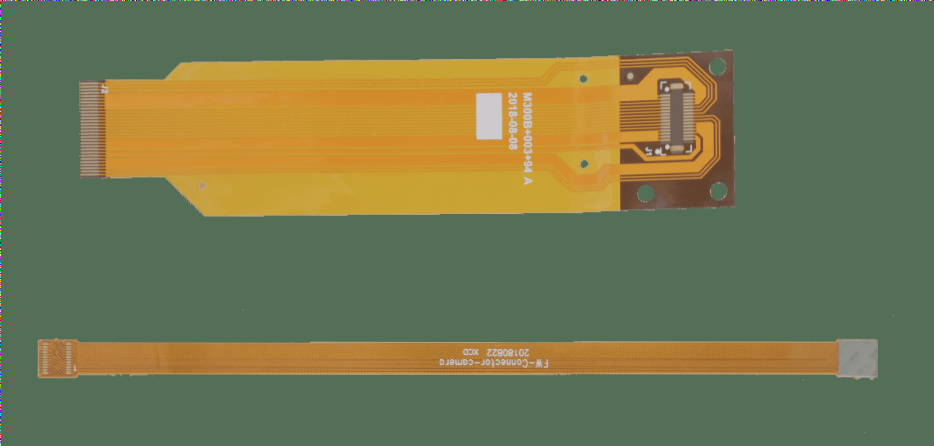

Why Use Stiffeners on Flex PCBs?

- Stiffeners are essential in flexible circuits to provide mechanical support and improve reliability.

- They help maintain appropriate thickness and reduce stress during bending operations.

- Stiffeners are crucial for components, connectors, and compliance with specifications like ZIF thickness.

- They enhance durability and reliability in various flexible circuit designs.

Types of Stiffener Materials

- Polyimide: Commonly used for FPC gold fingers and ZIF connectors.

- FR-4: Prevents bending near components and connectors to avoid damage.

- Aluminum & Stainless Steel: Provide heat dissipation and support in limited space areas.

Benefits of Using Stiffeners

- Keep flexible circuits upright when connecting components.

- Ensure flat and rigid surfaces for components like SMP pads.

- Reduce stress on solder pads for connectors inserted multiple times.

- Enhance durability and reliability in flexible circuit designs.

For more information, visit wellcircuits.com. Contact us for customized solutions to improve your business efficiency and stay ahead in your industry.

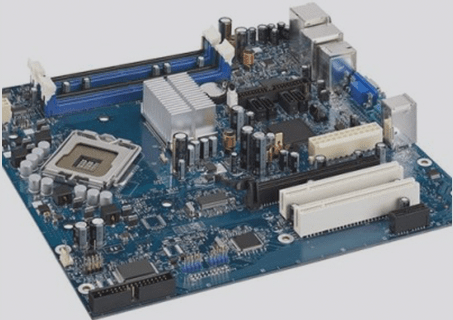

PCB Manufacturing Process

Introduction

PCB (Printed Circuit Board) is an essential component in electronic devices. It provides mechanical support and electrical connections for various electronic components.

PCB Design

The first step in PCB manufacturing is the design process. Designers use specialized software to create a layout that specifies the placement of components and routing of electrical connections.

Material Selection

Choosing the right materials is crucial for the performance and reliability of the PCB. Common materials include FR-4, a type of fiberglass epoxy laminate, and copper for the conductive traces.

Printed Circuit Board Production

During production, a layer of copper is laminated onto the substrate material. The excess copper is then etched away, leaving behind the desired copper traces.

Assembly

Components such as resistors, capacitors, and integrated circuits are then soldered onto the PCB. This process requires precision and accuracy to ensure proper functionality.

Testing

Once assembled, the PCB undergoes testing to verify its functionality and performance. This step is crucial in identifying any defects or issues that may affect the final product.

Conclusion

The PCB manufacturing process is a complex and intricate procedure that requires attention to detail and precision. By following strict guidelines and quality control measures, manufacturers can produce high-quality PCBs for a wide range of electronic devices.