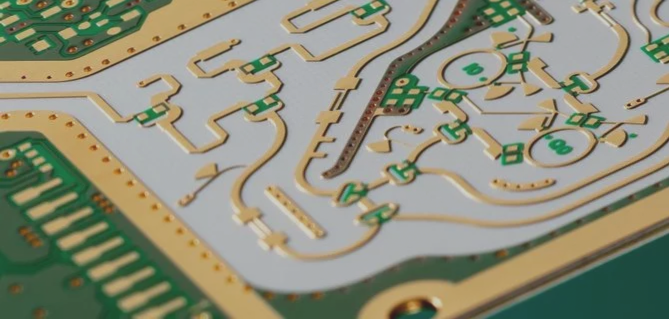

Rogers PCB Board Material: A Modern Solution for High-Performance Electronics

As a PCB expert, I can confidently say that Rogers PCB board material stands out as a modern and high-performance composite material in the electronics industry. Composed of glass fiber reinforcement and aromatic polyimide resin, processed through multi-layer composite processing, Rogers PCB boards offer a cutting-edge solution for various electronic applications.

Key Features of Rogers PCB Board Material:

- Excellent Dielectric Properties

- Good Electromagnetic Performance

- High Mechanical Strength

- High Reliability

Rogers PCB boards excel in high-frequency performance, dielectric strength, shielding capabilities, and long-term stability, making them ideal for advanced electronic devices.

Applications of Rogers PCB Board Material:

Rogers PCB board materials find extensive use in high-end electronic products such as mobile communication equipment, IT devices, aerospace electronics, and satellite navigation systems. In the era of 5G technology, Rogers PCB boards play a crucial role in meeting the high-frequency and high-speed transmission demands of modern communication systems.

Rogers Series Classification:

- RO4003, RO3003, RO4350, RO5880

- RO3000 series: RO3003, RO3006, RO3010, RO3035

- RT6000 series: RT6006, RT6010

- TMM series: TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i

With the continuous advancement in electronic technology, the future application prospects of Rogers PCB board materials are poised to expand further, solidifying their position as a cornerstone in high-end electronic devices.