Common Causes of Copper Foil Shedding on PCBs

Reason 1: Process Factors in PCB Manufacturing

- Copper foil shedding can occur due to manufacturing processes.

- Electrolytic copper foil used in PCB factories is typically single-sided galvanized or copper plated.

- Shedding is common with certain types of copper foil thicknesses.

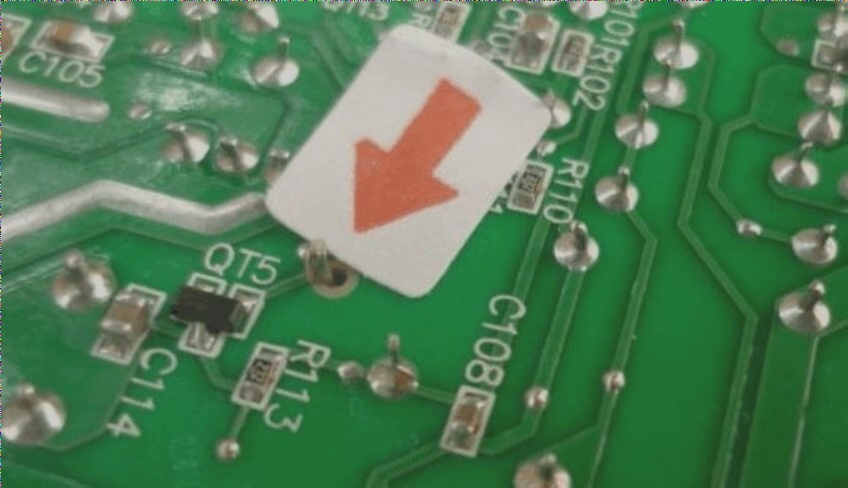

- Issues can arise from changes in copper foil specifications without corresponding adjustments to etching parameters.

- Inadequate washing and drying of PCBs after etching can weaken copper foil adhesion.

One scenario involves zinc-plated copper foil causing over etching of copper lines, leading to detachment. Proper washing and drying processes are crucial to prevent shedding, especially in humid conditions.

Reason 2: Customer’s PCB Design Factors

- Unreasonable PCB line design, such as using thick copper foil for thin lines, can lead to detachment.

Reason 3: PCB Material Related Factors

- Abnormalities in the peak value during copper foil production or plating can result in poor crystal branching, reducing peel strength.

- Compatibility issues between copper foil and resin systems can lead to inadequate adhesion strength of copper traces during assembly.

It’s essential to match the copper foil with the resin system to ensure proper adhesion and prevent shedding during electronic assembly.