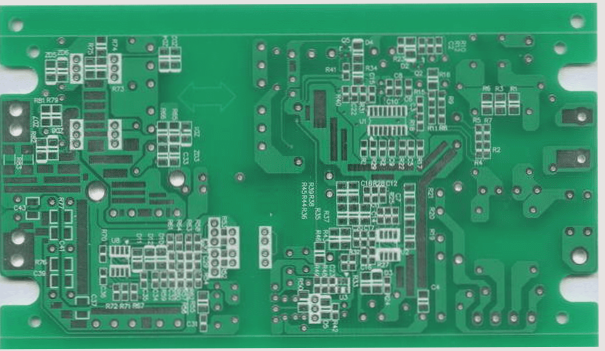

1. The multi-layer PCB process often encounters various complex issues, with process engineers frequently tasked with forensic analysis to determine causes and solutions. This discussion aims to explore these issues in detail, focusing on potential problems related to people, machines, materials, and conditions within the equipment area. Your contributions and insights would be greatly valued.

2. The multi-layer PCB process involves pre-treatment equipment, such as the inner layer pretreatment line, electroplating copper pretreatment line, D/F, and anti-welding (resistance welding) processes, among others.

3. Using the pre-treatment line for anti-welding (resistance welding) of hard board multi-layer PCBs as an example, the process generally includes: brushing and grinding (2 groups) -> water washing -> acid pickling -> water washing -> cold air knife -> drying section -> solar disc receiving -> discharging and receiving.

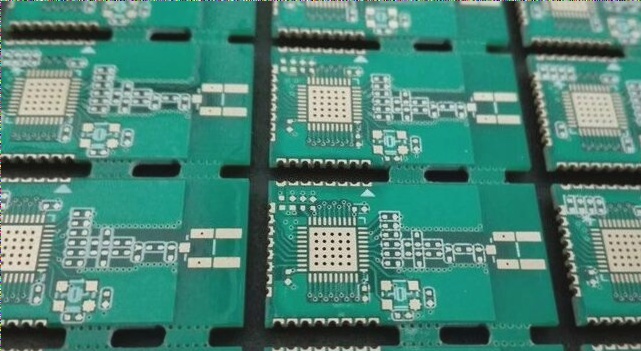

4. In the multi-layer PCB manufacturing process, steel brushes with #600 and #800 brush wheels are commonly used. These can impact the board surface’s roughness and the adhesion between ink and copper. Uneven product placement on the brush wheel can cause dog bones, leading to uneven surface coarsening, line deformation, and color discrepancies between the copper surface and ink. Therefore, a brush mark test is essential before brushing and grinding (including a water breaking test if applicable). Brush mark levels should be around 0.8–1.2mm, depending on the product. After replacing the brush, ensure the brush wheel level is corrected and lubricate it regularly. Insufficient water boiling or inadequate spray pressure during brushing and grinding can lead to copper powder issues, potentially causing micro short circuits or failed high-voltage tests in finished products.

Here’s a refined version of the article with each line retaining its original numbering:

Another common issue in the processing of multilayer PCBs is the oxidation of the board surface, which can result in bubbles or cavitation after H/A.

1. The solid water-retaining roller in the multilayer PCB pretreatment may be misaligned, leading to excessive acid being carried into the water-washing section. If the number of water-washing tanks in the subsequent section is insufficient or the water flow is inadequate, acid residues on the board surface may occur.

2. Poor water quality or impurities in the water-washing section during the multilayer PCB manufacturing process can also cause foreign materials to adhere to the copper surface.

3. If the water absorption roller is either too dry or overly saturated with water, it will be ineffective in removing water from the products. This can lead to excessive residual water on the board surface and in the holes, preventing the wind knife from performing its function effectively. Consequently, most of the resulting cavitation will appear as tears around the edges of the through-holes.

4. When multilayer PCBs are discharged while still at a high residual temperature, they may become folded, causing oxidation of the copper surface.

In the multilayer PCB process, the pH value of the water can be monitored with a pH detector, and the discharge residual temperature of the board surface can be measured using infrared technology. A solar disc retractor should be installed between the discharge and the stack plate retraction to cool the board. The wetting of the water absorption roller should be carefully controlled, ideally using two sets of water absorption rollers alternately. Additionally, the angle of the air knife should be checked before daily operation, and it is important to ensure that the air duct in the drying section is not detached or damaged.

2. The multi-layer PCB process involves pre-treatment equipment, such as the inner layer pretreatment line, electroplating copper pretreatment line, D/F, and anti-welding (resistance welding) processes, among others.

3. Using the pre-treatment line for anti-welding (resistance welding) of hard board multi-layer PCBs as an example, the process generally includes: brushing and grinding (2 groups) -> water washing -> acid pickling -> water washing -> cold air knife -> drying section -> solar disc receiving -> discharging and receiving.

4. In the multi-layer PCB manufacturing process, steel brushes with #600 and #800 brush wheels are commonly used. These can impact the board surface’s roughness and the adhesion between ink and copper. Uneven product placement on the brush wheel can cause dog bones, leading to uneven surface coarsening, line deformation, and color discrepancies between the copper surface and ink. Therefore, a brush mark test is essential before brushing and grinding (including a water breaking test if applicable). Brush mark levels should be around 0.8–1.2mm, depending on the product. After replacing the brush, ensure the brush wheel level is corrected and lubricate it regularly. Insufficient water boiling or inadequate spray pressure during brushing and grinding can lead to copper powder issues, potentially causing micro short circuits or failed high-voltage tests in finished products.

Here’s a refined version of the article with each line retaining its original numbering:

Another common issue in the processing of multilayer PCBs is the oxidation of the board surface, which can result in bubbles or cavitation after H/A.

1. The solid water-retaining roller in the multilayer PCB pretreatment may be misaligned, leading to excessive acid being carried into the water-washing section. If the number of water-washing tanks in the subsequent section is insufficient or the water flow is inadequate, acid residues on the board surface may occur.

2. Poor water quality or impurities in the water-washing section during the multilayer PCB manufacturing process can also cause foreign materials to adhere to the copper surface.

3. If the water absorption roller is either too dry or overly saturated with water, it will be ineffective in removing water from the products. This can lead to excessive residual water on the board surface and in the holes, preventing the wind knife from performing its function effectively. Consequently, most of the resulting cavitation will appear as tears around the edges of the through-holes.

4. When multilayer PCBs are discharged while still at a high residual temperature, they may become folded, causing oxidation of the copper surface.

In the multilayer PCB process, the pH value of the water can be monitored with a pH detector, and the discharge residual temperature of the board surface can be measured using infrared technology. A solar disc retractor should be installed between the discharge and the stack plate retraction to cool the board. The wetting of the water absorption roller should be carefully controlled, ideally using two sets of water absorption rollers alternately. Additionally, the angle of the air knife should be checked before daily operation, and it is important to ensure that the air duct in the drying section is not detached or damaged.