At this stage, non-ODS cleaning processing technology can be utilized, including water-based cleaning, semi-aqueous cleaning, organic solvent cleaning, and no-clean processing. The decision should be based on the requirements of the electronic equipment, the necessity of cleaning quality, and the specific conditions of the processing plant.

Water-based cleaning

1.1 Water-based cleaning processing technology

Water-based cleaning processing technology employs water-based cleaning materials. To enhance cleaning effectiveness, a small amount of surfactants, cleaning modifiers, desulfurizers, and other compounds can be added to the water (generally 2%≤10%). The details of environmental pollution with different characteristics on printed circuit boards can be utilized as preservatives in water-based cleaning agents, broadening their cleaning applications. Water-based cleaners are effective for water-soluble stains.

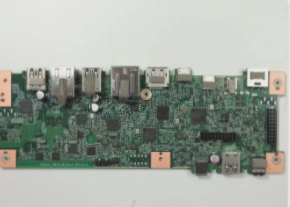

The common metal PCB consists of an aluminum core combined with standard FR-4. In essence, it features a three-layer metal core. Since the aluminum-based PCB includes a heat rejection layer, the operating temperature of the components can be reasonably lowered, thereby enhancing the lifecycle of the products. Compared to traditional FR-4 boards, aluminum-based PCB circuit boards exhibit superior thermal conductivity. The metal layer of the aluminum-based PCB rapidly dissipates the heat generated by the components, effectively reducing the heat transfer coefficient and offering excellent thermal conductivity.

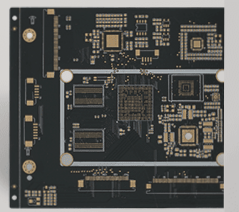

The PCB board exhibits high density. Over the past few decades, the increasing density of PCBs has coincided with advancements in integrated circuit chip processing speeds and mounting technology. This ensures high reliability. Through a series of inspections, testing, and aging assessments, the long-term service life of a PCB is guaranteed to be 20 years, enabling dependable operation and design solutions. The various characteristics of PCB, including physical, organic, chemical, and mechanical properties of electrical equipment, can be designed in accordance with standardized design plans, resulting in shorter timeframes and higher efficiency.

Lead-free tin spraying is an environmentally friendly process that poses minimal harm to humans. The current guideline stipulates that the lead content in lead-free tin should not exceed 0.5%. Lead-free tin will dissolve at a higher rate, resulting in stronger solder joints. Essentially, lead spray and lead-free spray are similar processes, differing primarily in the purity of lead used. Lead-free tin is safer for the natural environment, aligning with future development trends. This article details the characteristics and disadvantages of both lead spray tin and lead-free tin spray. Given concerns about safety and environmental impact, it is recommended to adopt lead-free tin spraying, which is non-toxic and harmless. This approach is also the metal surface treatment technology currently promoted.

—

Let me know if you need any further adjustments!