Diverse Requirements for PCBs Based on Signal Frequencies

- PCBs operating below 1GHz often utilize FR4 due to cost-efficiency and established multi-layer pressing techniques. However, challenges arise with low impedance signals, necessitating careful consideration of transmission line characteristics and inter-line coupling during wiring.

- For optical fiber communication products above 622Mb/s and small signal microwave transceivers between 1GHz and 3GHz, materials like S1139 offer stable dielectric constants up to 10GHz, albeit at a slightly higher cost than FR4.

- RO4000 series, such as RO4350, cater to microwave circuits below 3GHz requiring robust signal handling, offering stable dielectric constants and heat resistance comparable to FR4.

- Microwave circuits above 10GHz demand high-performance boards akin to F4, especially for applications like power amplifiers and frequency converters.

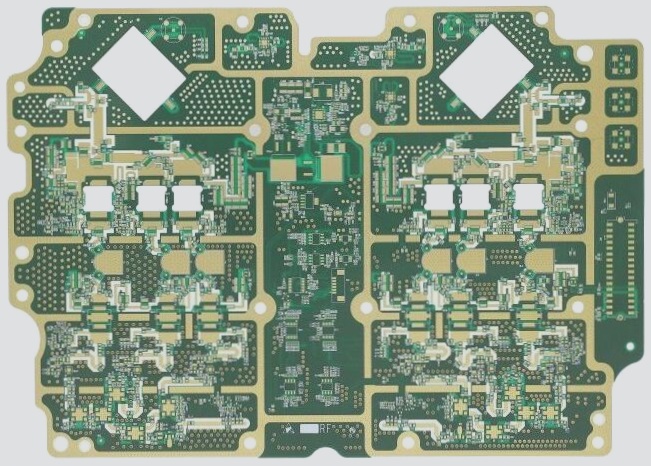

- For multilayer PCBs in wireless mobile phones, substrates with low dielectric constants and high shielding capabilities are preferred, with options ranging from PTFE-based materials to composite laminates combining FR4 and high-frequency boards.

Consider these factors when selecting the appropriate PCB for your specific frequency requirements.