1. Simply put, when it comes to boosting, only DC/DC can be utilized, as LDOs are voltage drop types and cannot perform boosting.

Selection of LDO:

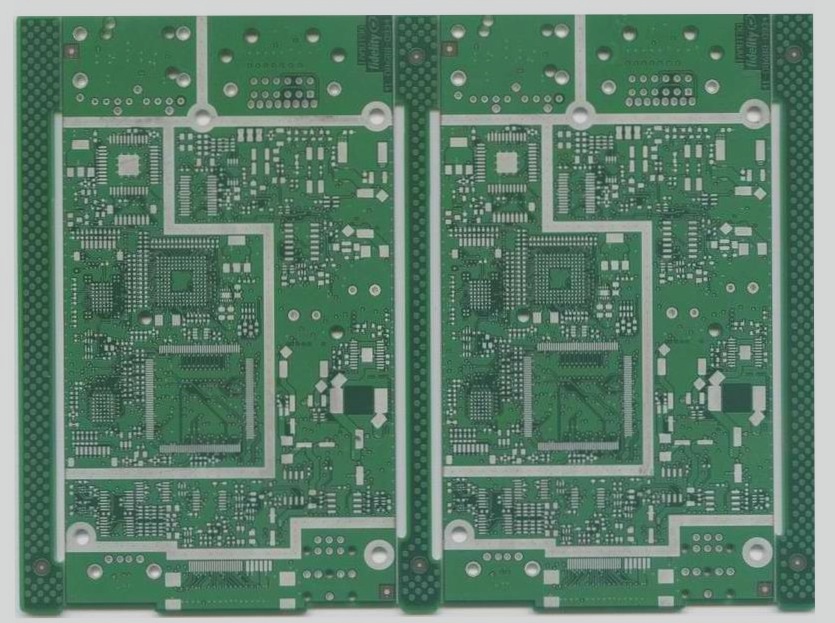

When the designed circuit necessitates shunt power supply with the following requirements, LDO emerges as the most suitable choice to fulfill various demands of product design.

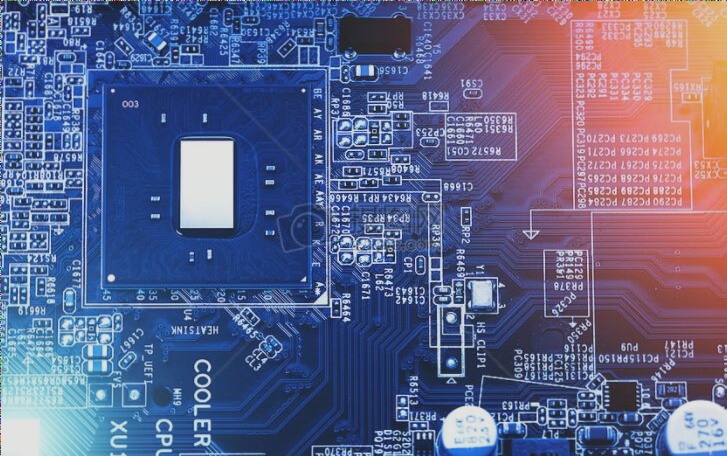

DC/DC: High efficiency with high noise; although it boasts high conversion efficiency and large current capacity, it also introduces significant output interference and relatively large volume.

LDO: Low noise with low quiescent current; compact size, minimal interference. However, its conversion efficiency diminishes notably when faced with substantial input-output voltage differentials.

Hence, in scenarios entailing a considerable voltage drop, DC/DC is preferred due to its efficiency, whereas LDO would incur substantial efficiency losses. Conversely, when encountering a relatively minor voltage drop, selecting LDO is advantageous for its low noise, clean power supply, simplified peripheral circuits, and cost-effectiveness.

LDO, or low dropout regulator, signifies a low dropout linear regulator, contrasting with traditional linear regulators like the 78xx series chips. Traditional linear regulators necessitate the input voltage to surpass the output voltage by 2V~3V for proper functioning. However, in cases like 5V to 3.3V conversion, where the input-output pressure difference is merely 1.7V, such conditions prove too stringent. To address this, LDO type power conversion chips are introduced.

LDO Linear Step-Down Chip: Operates akin to a resistor divider for step-down, incurring significant energy loss converted into heat. The chip’s heat generation amplifies with higher pressure differences and load currents during step-down. These chips typically feature larger packages, aiding heat dissipation.

Examples include 2596 and L78 series chips.

DC/DC Step-Down Chip: Exhibits relatively minimal energy loss during step-down, resulting in less noticeable chip heating. These chips come in smaller packages and support PWM digital control.

Examples include TPS5430/31, TPS75003, MAX1599/61, TPS61040/41.

In PCB design, DC/DC is the standard choice for step-up applications. However, for step-down applications, the selection between DC/DC and LDO hinges upon cost, efficiency, noise, and performance, emphasizing the importance of tailored analysis for specific applications.