PCB Coating Methods and Pre-Baking Process

- Coating Methods:

- Screen Printing: A cost-effective method with low equipment requirements, suitable for small and medium manufacturers.

- Roller Coating: Enables simultaneous coating on both sides, ideal for high-volume production.

- Curtain Coating: Ensures even coating thickness but requires high equipment standards.

- Considerations for Coating Operation:

- Ensure a clean environment with yellow light, room temperature 23-25°C, and humidity 55±5%.

- Watch out for pinholes, adjust coating thickness, and prevent ink from entering holes.

- Maintain uniform coating thickness of 8-15um and good ventilation due to solvent content.

- Pre-Baking Process:

- Pre-Baking Methods: Drying tunnel and oven, with oven drying being more common.

- Control temperature and time: 80±5°C for 10-15 minutes for the first side, and 15-20 minutes for the second side.

- Importance of Pre-Baking: Ensures consistent development effect, faster development, and good graphic quality.

- Precautions for Pre-Baking:

- Air-cool the board after pre-baking before exposure to negative film.

- Avoid natural drying to prevent poor exposure; aim for a film hardness of HB~1H.

Important Tips for PCB Manufacturing Process

- If using an oven for pre-baking, ensure it has blast air and constant temperature control for uniform temperature. Keep the oven clean to prevent impurities from damaging the film surface.

- After pre-baking, avoid exceeding 48 hours from coating to developing. In high humidity conditions, aim to expose and develop within 12 hours.

- For different types of liquid photoresists, carefully read the instructions and adjust process parameters like thickness, temperature, and time based on production practices.

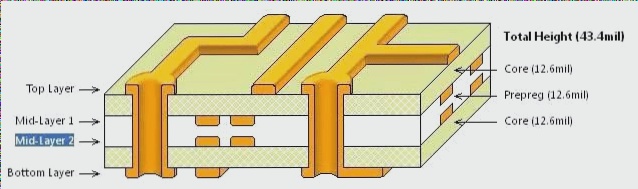

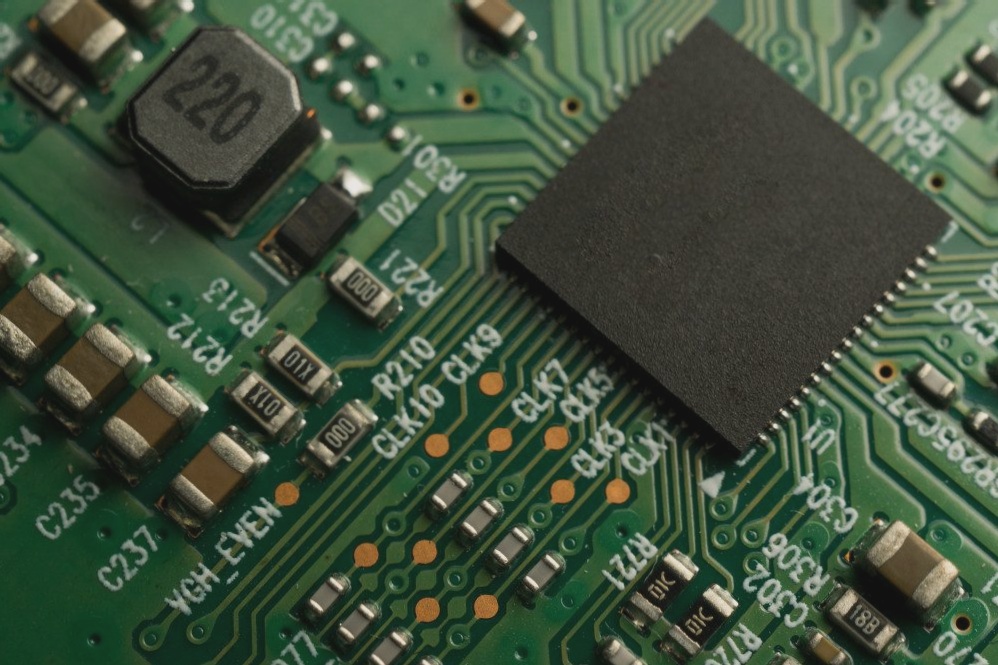

Challenges in High-Density Interconnect Technology (HDI)

As the use of HDI technology expands, PCB manufacturers face challenges in resolution and positioning. Higher circuit density requires more precise positioning methods, including:

- Visual Positioning: Align a Diazo film with the printed board hole through the pattern for accurate alignment. This method is effective for both Diazo and Silver Films.

- Movable Pin Positioning: Utilize a photographic film puncher and a double-hole de-pin locator for precise alignment during drilling and exposure.

- Fixed Pin Positioning: Employ two pin systems to fix the photographic plate and the PCB, adjusting positions for proper alignment.