PCB Circuit Boards Testing and Evaluation

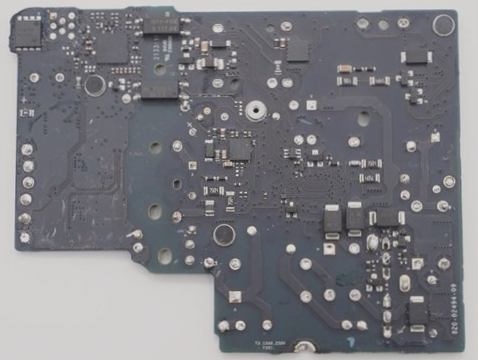

When designing PCB circuit boards, it is crucial to understand the numerical relationships, such as voltage and current, between different test points. During the PCBA processing workflow, which includes PCB manufacturing, component procurement, SMT assembly, DIP insertion, and PCBA testing, issues may arise due to equipment malfunction or improper handling.

Professionally testing the PCBAs is essential to ensure they meet design specifications and are free of quality defects. Rigorous electrical and performance evaluations are conducted before shipping the products to customers.

PCBA Testing Methods

PCBA circuit boards undergo FCT (Functional Testing) and ICT (In-Circuit Testing) of electrical components. Initially, ICT was the dominant testing method, especially for large electronic product design companies in industries like mobile phones.

Shift to FCT Testing

With advancements in the semiconductor industry leading to higher component density, many PCBA manufacturing plants are moving towards FCT functional testing over ICT. FCT testing is cost-effective and tailored to customer design requirements.

ICT equipment costs significantly more than FCT testing, making it less feasible for small to medium-sized enterprises. FCT testing is becoming more customized, with test fixtures and platforms designed according to specific customer needs.

The market trend is shifting towards incorporating FCT capabilities into ICT equipment, but challenges remain in standardizing FCT functions. Customization based on customer models and products is favored, particularly in flexible production scenarios.