Sensor Technology in SMT Placement Machines

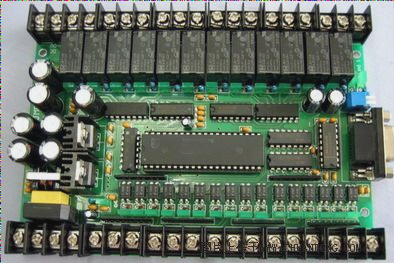

When it comes to SMT placement machines, sensors play a crucial role in ensuring smooth operations. Let’s explore some key sensors used in these machines:

- Pressure Sensor: Monitors air pressure levels to ensure proper machine operation.

- Negative Pressure Sensor: Controls component pick-up using negative pressure.

- Position Sensor: Essential for accurate transmission and positioning of PCBs.

- Image Sensor: Provides real-time feedback on the machine’s working status.

Best Practices for Patch Processing in SMT

SMT chip processing is a vital part of electronics assembly, and following these tips can help ensure a successful outcome:

- Tin one end of SMD RC components before soldering to the PCB.

- Apply flux before soldering to prevent poor tinning or oxidation.

- Keep the soldering iron tip parallel to the pin for precise soldering.

- Handle PQFP chips carefully to avoid pin damage during placement.

- Use flux to clean solder residues after completing the soldering process.

By following these guidelines, you can improve the efficiency and quality of your SMT assembly process.