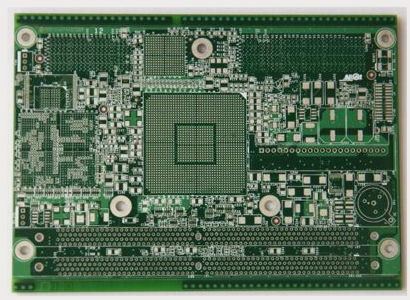

The Importance of Process Edges in PCB Manufacturing

During the PCB manufacturing process, reserving process edges is crucial for subsequent SMT chip processing. These edges assist in producing the plug-in board and are essential for wave soldering on two or four sides of the PCB. While they are not part of the final PCB and can be removed after manufacturing, their proper design is vital for efficient production.

Key Considerations for PCB Process Edges

- Process edges consume additional PCB material and increase costs, so balancing economic efficiency and operability is essential in their design.

- For uniquely shaped PCBs, simplification can be achieved using a splicing method, especially for boards wider than 350mm.

- It is crucial to maintain a process edge of about 2-5mm to prevent components from being picked up by the SMT nozzle during operation.

- Ensuring the flatness of process edges is critical to avoid misalignment issues during assembly.

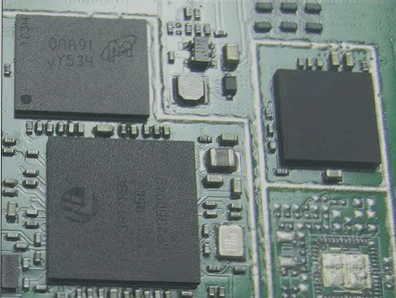

Advantages of Automotive Circuit Board PCBs

PCB circuit boards play a vital role in electronic devices, providing power and enabling the operation of connected equipment. Some key advantages of PCBs include:

- Support for high-density designs that evolve with integrated circuit technology advancements.

- High reliability achieved through rigorous inspections, tests, and aging assessments.

- Design flexibility to meet various performance requirements efficiently.

- Manufacturability benefits from modern management practices for consistent quality.

- Testability ensured by a range of testing methods to assess product eligibility and lifespan.

- Assemblability for standardized integration of components, supporting large-scale production.

- Maintainability enhanced by standardized production, enabling quick and flexible part replacement.