The transmission rate of high-speed PCB design and wiring systems is accelerating with the changing times. However, this advancement also brings forth a new challenge: declining anti-interference capability. This trend is primarily driven by the increasing frequency of transmitted information, which makes signals more sensitive while decreasing their energy. Consequently, wiring systems are becoming increasingly susceptible to interference. In common electronic devices like computer screens, mobile phones, motors, and radio broadcasting equipment, cables and devices often interfere with other components or are significantly affected by external sources of interference.

Especially when high-speed PCB data networks are utilized, the time required to intercept a large amount of information is significantly shorter than that needed for intercepting low-speed data transmissions. Twisted pairs in data cables can resist external and inter-pair interference at lower frequencies due to their inherent twist structure. However, at higher frequencies (especially above 250MHz), effective interference suppression cannot be achieved through twisting alone; shielding becomes necessary to counter external interference. As the transmission rates in high-speed PCB designs continue to rise, they introduce increased susceptibility to jamming. This heightened vulnerability stems from the heightened sensitivity of signals as their frequencies increase, coupled with their decreased energy. Consequently, the wiring systems become more prone to interference, whether from adjacent cables, equipment, or external sources like computer monitors, mobile phones, motors, radio relay equipment, and power lines. Moreover, the risks posed by potential eavesdroppers, network criminals, and hackers are escalating due to the substantial damage and losses that can result from intercepting UTP cable transmissions.

The function of cable shielding is akin to a Faraday shield, wherein the shielding layer absorbs interfering signals before they can reach the conductor, ensuring uninterrupted data transmission. Shielded cables emit lower levels of electromagnetic radiation compared to unshielded ones, thereby reducing the risk of interception in network transmissions. Shielding strategies vary depending on the type of interference encountered, primarily electromagnetic interference (EMI) and radio frequency interference (RFI). EMI, predominantly low-frequency interference, originates from sources such as motors, fluorescent lamps, and power lines. RFI, on the other hand, encompasses high-frequency PCB interference from sources like radio and television broadcasts, radar, and wireless communications. Braided shielding proves most effective against EMI due to its low critical resistance, whereas foil shielding is preferred for RFI because of its efficiency in blocking high-frequency signals. In environments where both high and low-frequency interferences are present, a combination of foil and braided shielding provides broad-spectrum coverage.

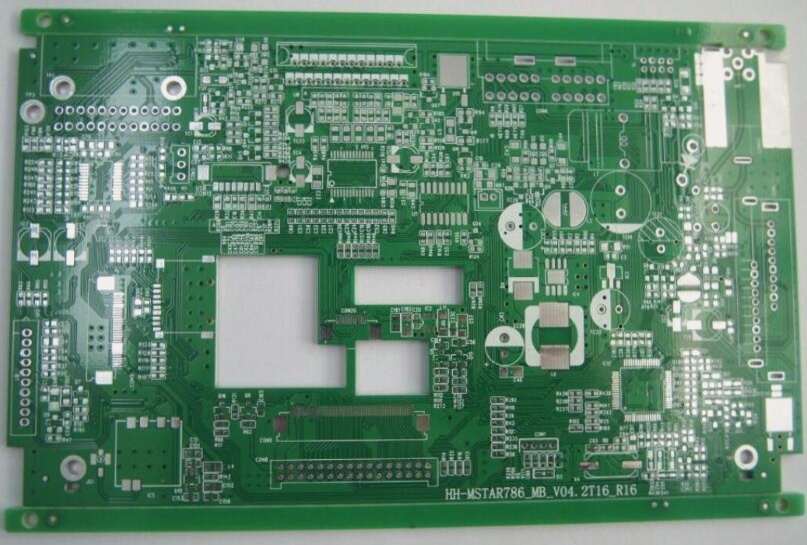

In terms of signal integrity (SI), the ideal scenario in PCB boards involves undistorted signal transmission from the transmitter (Tx) to the receiver (Rx). However, practical considerations such as impedance mismatch, crosstalk, attenuation, reflection, and switching issues result in signal degradation. SI is crucial in high-frequency environments as it assesses and mitigates these distortions through practical solutions. Designing high-speed PCBs requires viewing routing as transmission lines rather than mere wires. Identifying the highest operating frequency aids in identifying critical routing paths that must be treated as transmission lines. Generally, routing lengths exceeding approximately one-tenth of the wavelength of the operating frequency qualify as transmission lines, necessitating both digital and analog analyses.

The choice of PCB substrate material also impacts SI, as each material possesses a unique relative dielectric constant (ε R). This constant influences signal propagation characteristics such as velocity (V p) and propagation delay (t PD), which in turn dictate the length of cable that must be treated as a transmission line to preserve SI. The figure below illustrates how insertion loss increases with signal frequency, highlighting differences between materials like FR-4 (glass epoxy) and high-frequency PCB Rogers RO4350B, where higher insertion loss correlates with greater attenuation.