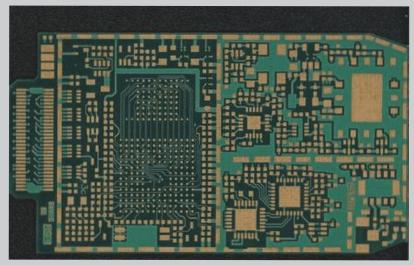

Understanding Signal Reflow and Cross-Segmentation in High-Speed PCB

What is Signal Reflow and Cross-Segmentation?

Signal reflow and cross-segmentation play crucial roles in high-speed PCB design. In this context, IC1 serves as the signal output terminal, while IC2 acts as the signal input terminal. The third layer functions as the ground layer, with both IC1 and IC2 connecting to this common ground plane. Additionally, a power plane in the top layer connects to the positive terminal of the power supply. Decoupling capacitors C1 and C2 are strategically placed to support the respective ICs.

Impact at Low and High Frequencies

At low frequencies, the current loop flows from the power supply through IC1 to IC2 and back. However, at high frequencies, the PCB’s distribution characteristics significantly affect the signal. Ground return issues arise due to increased current in the signal line, inducing reverse currents in nearby conductors.

Minimizing External Interference

To minimize external interference, a complete ground plane and power plane are essential. By creating the smallest current loop, energy radiation externally is reduced, enhancing signal integrity. Decoupling capacitors play a vital role in stabilizing power distribution and minimizing signal path disruptions.

Addressing Crosstalk Challenges

For high-speed signals like clock signals accompanied by data lines, crosstalk can disrupt signal integrity. Proper matching of signal paths is crucial to mitigate crosstalk effects. Understanding the rate of current change and load characteristics is key to managing crosstalk in PCB designs.

Conclusion

Effective signal reflow and cross-segmentation are essential in high-speed PCB designs to ensure signal integrity and minimize external interference. By strategically designing current paths and addressing crosstalk challenges, PCB designers can optimize performance and reliability in electronic systems.

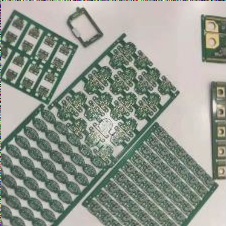

Maximizing PCB Signal Return Paths

Adjacent power planes can serve as return paths for signals when equipped with suitable capacitors at both ends to ensure a low-reactance connection to ground. In typical setups, decoupling capacitors ranging from 0.01 to 0.1 µF are placed between each power supply and ground, enhancing the return effect of the power plane.

However, utilizing other power planes for return flow may lead to challenges, as these planes often lack low-reactance paths to ground. In such cases, induced current in the adjacent plane will seek the nearest capacitance to return to ground, potentially causing common ground interference similar to crosstalk.

For scenarios involving cross-supply splitting, incorporating capacitors or high-pass filters can be beneficial. Tailoring the values to your signal type can establish a high-frequency return path on the PCB while isolating low-frequency crosstalk between planes.

When using alternative planes for return flow, consider adding multiple small capacitors to ground at both signal ends to facilitate the return path. This may pose challenges due to space constraints near terminals occupied by matching resistors and decoupling capacitors.

If you require PCB manufacturing services or have any inquiries, feel free to contact us.