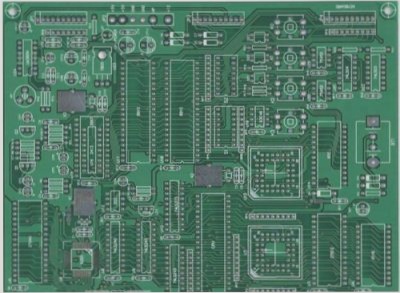

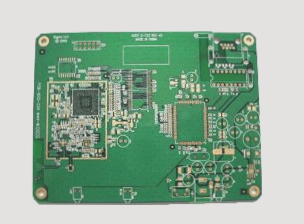

Optimized Pre-Treatment Process for PCB Fabrication

After conducting numerous experiments based on the company’s specific conditions, the pre-treatment process for PCB fabrication has been thoroughly optimized, leading to successful outcomes.

Pre-Treatment Process Flow:

- Water Pre-Soaking

- Pickling

- Water Cleaning

- Brushing

- High-Pressure Water Washing

- Municipal Water Washing

- Water Roller Squeezing

- Cold Air Drying

- Hot Air Drying

Specific Operations and Precautions:

- Water Pre-Soaking: Essential for removing impurities and accelerating pickling. Control machine speed to prevent surface damage.

- Pickling: Use 5-10% sulfuric acid solution for 1 minute to eliminate impurities. Rinse with city water afterward.

- Brushing the Board: Employ 300-mesh and 500-mesh brushes carefully to enhance mechanical action without causing scratches.

- High-Pressure Water Washing: Maintain pressure above 12.5bar to ensure thorough cleaning and insulation resistance.

- Water Squeezing Rollers: Utilize three sets of rollers to remove excess water and prolong their lifespan.

- Cold Air Drying: Prevent oxidation by blowing out water and controlling wind direction.

- Hot Air Drying: Dry board surface and holes at 75-85℃ for proper ink adhesion post-silkscreen solder mask application.

By following these optimized processes and parameters, the PCB pre-treatment ensures high-quality results and efficient production.