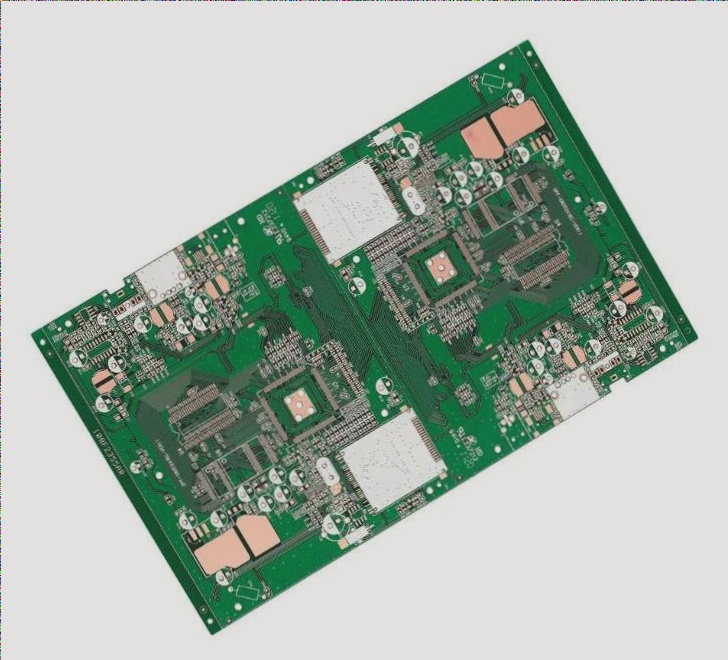

The Importance of Vias in PCB Design

Vias are crucial components in multi-layer PCBs, with drilling costs typically making up a significant portion of the overall manufacturing cost. A via consists of a drill hole and a pad area, determining its size and impact on the circuit design.

Design Considerations for Vias

- For high-speed, high-density PCB designs, smaller via holes are preferred to maximize wiring space and reduce parasitic capacitance.

- However, reducing via size increases costs and is limited by drilling and plating processes.

- Recommended via hole diameters are 0.2mm (inner) and 0.4mm (outer), with common sizes following X*2±2mil.

- Avoid using buried blind vias for BGA designs above 0.65mm to control costs.

- Place vias at a distance from pads to prevent solder paste issues and tombstone phenomena.

- Maintain a minimum hole spacing of 0.5mm to prevent drilling issues.

- Vias ≤0.5mm, except for heat dissipation, should be plugged to prevent short circuits.

- Ensure equidistant positioning of vias from BGA pads to avoid engineering problems and welding quality issues.

- Use fixed pads with vias for earphone terminals, buttons, and FPCs to enhance stability.