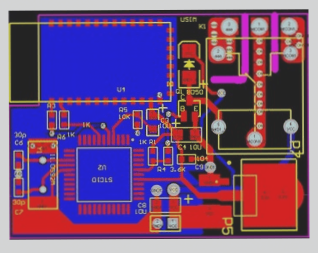

Factors to Consider When Selecting Component Packaging in PCB Design

- Consider the selection of component packaging

When designing a PCB, it is crucial to consider various factors when selecting component packaging. Here are some key points to keep in mind:

1. Electrical and Mechanical Considerations

Component packaging involves not only the electrical pad connections but also the mechanical dimensions (X, Y, and Z) of the component. It is essential to consider the shape of the component body and its pins connected to the PCB. For instance, components like polar capacitors may have height limitations that need to be taken into account during the selection process.

2. Custom Package Creation

If a ready-made package is not available in the database, it is common practice to create a custom package within the design tool.

3. Grounding Methods

Implement effective grounding by incorporating bypass capacitors and ground planes into the design. Placing decoupling capacitors near the power terminal and ground of integrated circuits can enhance electromagnetic compatibility and susceptibility.

4. Virtual Component Allocation

Review virtual components in the bill of materials (BOM) and replace them with packaged components before transitioning to the layout stage.

5. Bill of Materials Data

Ensure that the BOM report contains complete data, including device, supplier, and manufacturer information for all components.

6. Gate Circuit Optimization

Avoid floating input terminals in redundant gate circuits to prevent system failure. Properly utilize all components in ICs to ensure normal operation.

By considering these factors, you can optimize the component selection process in PCB circuit board design.